The Art of Metal Injection Molding批发, An Insight into the World of Hardware Manufacturing

Metal injection molding, also known as molded metal parts or metal injection molding, is a process used to produce complex metal components. The process involves injecting molten metal into a precision-engineered plastic mold and allowing it to cool before removing the finished part from the mold. This technique has become increasingly popular in the hardware manufacturing industry due to its high accuracy, repeatability, and speed of production. The art of metal injection molding requires skilled technicians who have a deep understanding of the process and are capable of producing parts with precise dimensions and tolerances. The process begins with the selection of a suitable material, such as aluminum or zinc, and the creation of a mold that can withstand the high temperatures involved in the injection process. Once the mold is ready, the molten metal is injected into it, followed by a series of intricate cooling and shaping operations. Metal injection molding has many benefits over traditional manufacturing methods. It allows for rapid prototyping and low-volume production, making it ideal for small businesses and startups looking to bring their products to market quickly. In addition, it offers high strength and durability, making it suitable for use in demanding applications such as aerospace, automotive, and medical equipment. In conclusion, metal injection molding is an essential tool in the hardware manufacturing industry. Its ability to produce complex metal components with high accuracy and speed makes it a valuable asset for businesses looking to improve their production processes and stay ahead of the competition. As technology continues to evolve, it is likely that metal injection molding will become even more prevalent in the manufacturing sector.

Introduction

Metal injection molding (MIM) is a popular manufacturing technique used to create high-quality metal components. This process involves injecting a molten metal alloy into an intricately designed mold, which then solidifies and takes on the shape of the desired part. MIM has revolutionized the manufacturing industry, particularly in the field of hardware production, by enabling the creation of complex shapes and designs that were previously impossible to produce using traditional methods. In this article, we will explore the basics of MIM, its applications in various industries, and the role it plays in the global hardware manufacturing landscape.

The Basics of Metal Injection Molding

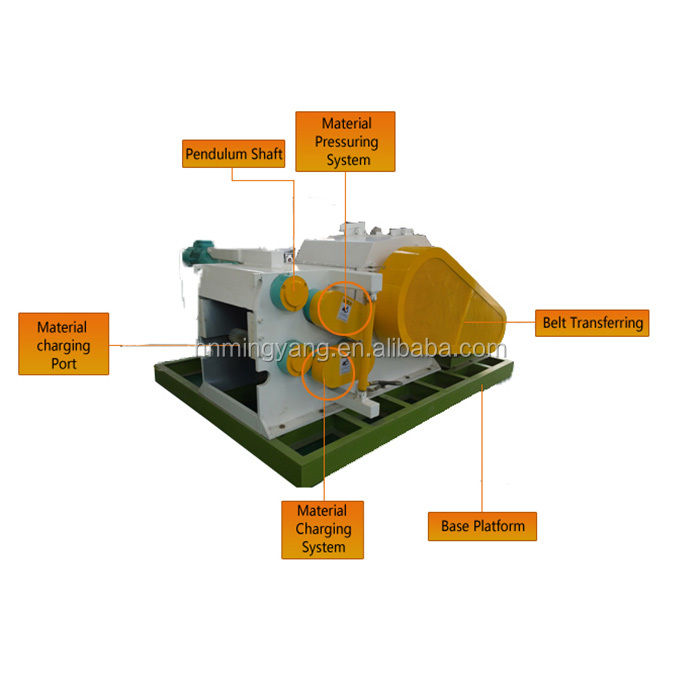

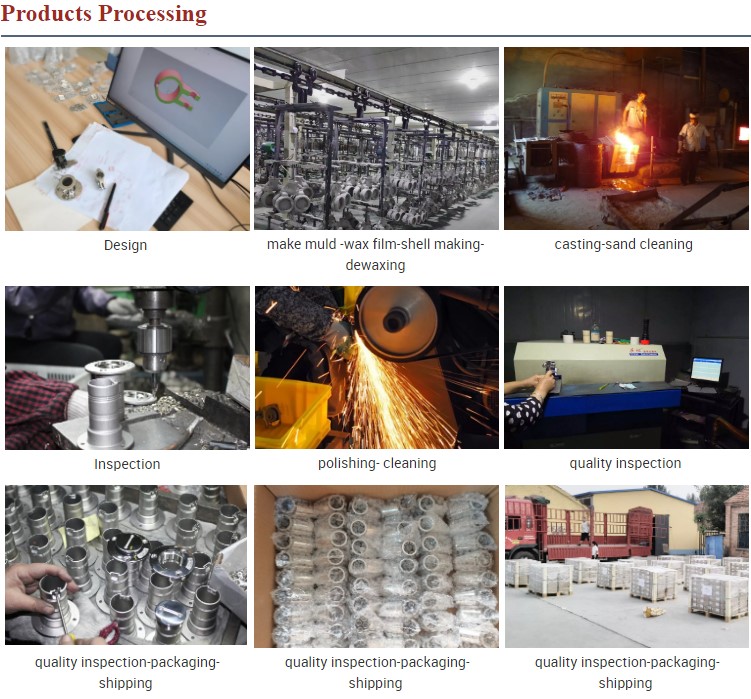

MIM is a type of additive manufacturing process that involves three main stages: the mold design, the material preparation, and the injection molding itself. The mold design is critical as it determines the complexity and accuracy of the final part. The material preparation involves selecting the appropriate metal alloy and preparing it for injection into the mold. Once the mold is ready, the injection molding process begins, where a high-pressure gas or liquid is used to inject the molten metal into the mold cavity. The metal cools and solidifies, taking on the shape of the mold. The finished part is then removed from the mold and subjected to post-mold processing to ensure it meets the required quality standards.

Applications in Various Industries

The versatility of MIM makes it an ideal technology for producing a wide range of metal components across various industries. Some of the most common applications include:

1、Automotive Industry: MIM is widely used in the automotive industry to produce complex parts such as engine components, gearboxes, and suspension systems. These parts require high precision and strength, and MIM enables manufacturers to produce them with exceptional accuracy and efficiency.

2、Electronics Industry: The electronics industry relies heavily on metal components such as printed circuit boards (PCBs), electronic enclosures, and microcontroller chips. MIM allows manufacturers to produce these components with intricate details and precise dimensions, ensuring they meet the demanding performance specifications.

3、Medical Industry: The medical industry requires precision-engineered metal components such as prosthetic limbs, dental implants, and surgical instruments. MIM offers high-quality materials that are biocompatible and suitable for human use, making it an ideal choice for manufacturing these critical components.

4、Aerospace Industry: The aerospace industry demands high-performance metal components such as aircraft engines, fuel systems, and structural components. MIM enables manufacturers to produce these components with exceptional strength, durability, and resistance to corrosion, ensuring their reliability and safety in extreme environments.

5、Defense Industry: The defense industry requires durable metal components for military equipment, vehicles, and weapons systems. MIM allows manufacturers to produce these components with high strength, resistance to wear and tear, and compatibility with various materials used in military applications.

Global Landscape of Hardware Manufacturing

The global hardware manufacturing industry is a significant contributor to economic growth and employment opportunities worldwide. However, it faces several challenges such as increased competition, rising costs, and environmental concerns. To address these challenges, manufacturers are turning to advanced technologies such as MIM to enhance their productivity, efficiency, and product quality.

In recent years, there has been a growing trend towards customization and personalization in hardware manufacturing. This shift has created new opportunities for manufacturers who can offer unique products tailored to customer needs. Additionally, advancements in 3D printing technology have enabled some manufacturers to produce prototypes quickly and at lower costs, further challenging traditional manufacturing methods. As a result, many hardware manufacturers are exploring partnerships with technology companies like Google and Microsoft to incorporate cutting-edge technologies like AI and cloud computing into their operations.

Conclusion

Metal injection molding (MIM) is a powerful technology that has transformed the world of hardware manufacturing by enabling the creation of complex shapes and designs that were previously impossible to produce using traditional methods. With its ability to produce high-precision metal components with exceptional accuracy and efficiency, MIM is becoming increasingly popular in various industries such as automotive, electronics, medical, aerospace, and defense. As manufacturers continue to adopt advanced technologies like MIM in response to market trends and changing customer demands, we can expect to see even more innovation and growth in the global hardware manufacturing landscape in the coming years.

Articles related to the knowledge points of this article:

High-end Bathroom Hardware Wholesale: Quality, Selection, and Savings

Title: Alibaba五金批发网, Your One-Stop Solution for All Metal Products and Components

Title: Exploring the World of Hardware Wholesale in Hebei Province