Customizing Hardware Display Shelves: Design, Material, and Process

The process of customizing hardware display shelves involves three key aspects: design, material, and process. The design phase requires careful consideration of the specific requirements and objectives of the display. This includes determining the type of hardware to be showcased, the target audience, and the overall style and theme of the display.The material selection for hardware display shelves is crucial. Common materials include wood, metal, and plastic. Each material has its own unique properties and aesthetic appeal, so it is essential to choose a material that will complement the design and meet the practical needs of the display.Finally, the process of manufacturing the display shelves is important. This includes cutting, shaping, and finishing the material to create a smooth and aesthetically pleasing surface. The manufacturing process should be tailored to ensure that the final product meets all of the design specifications and is durable enough to withstand the weight and use of the hardware being showcased.Overall, customizing hardware display shelves requires a combination of careful design, material selection, and manufacturing process to create a display that will effectively showcase the hardware and engage the target audience.

The world of hardware display shelves is filled with an array of choices and possibilities. From the materials used to the design specifications, every aspect of a hardware display shelf’s creation can be customized to meet the unique needs of a business or individual. In this article, we explore the process of customizing hardware display shelves, focusing on design, material, and process.

Design

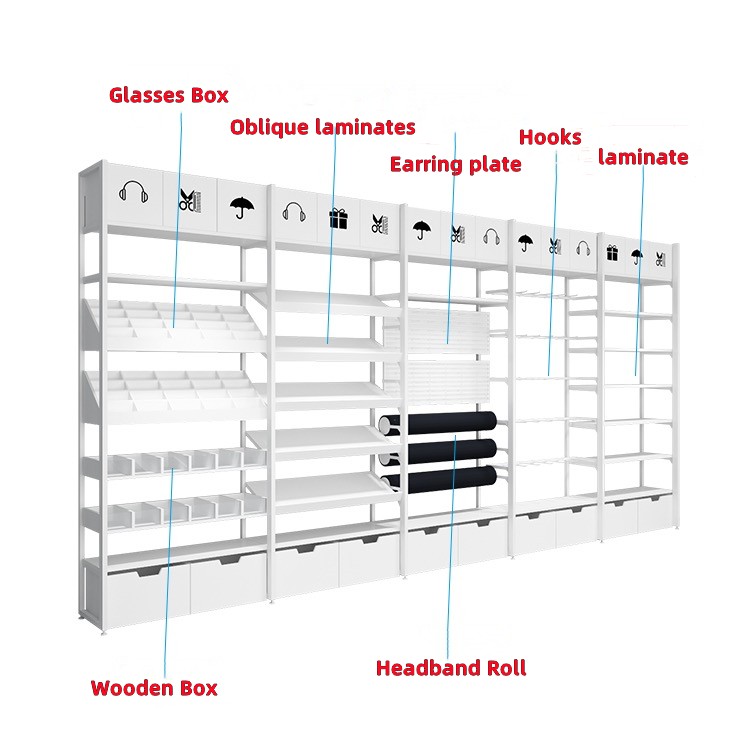

The design phase of a hardware display shelf’s creation is where the vision of its purpose and form are brought together. Whether it’s a simple shelf for storing tools or a complex display system for showcasing products, the design phase involves understanding the requirements of the user and creating a visual representation of the finished product. Customizing the design allows for the creation of a unique piece that not only meets the user’s needs but also enhances their environment. By working closely with the client, designers can create a product that is tailored to their specific requirements, ensuring a perfect fit and maximizing impact.

Material

The material used in the construction of a hardware display shelf is crucial to its durability, longevity, and overall performance. Common materials include steel, aluminum, and wood, each offering its own set of advantages and disadvantages. For example, steel is strong and durable but may rust over time, while aluminum is lightweight and resistant to corrosion but may not be as strong as steel. Wood, on the other hand, is a sustainable and aesthetically pleasing material that can be easily customized but may not be as durable as metal. By understanding the specific requirements of the user and the environment in which the shelf will be used, manufacturers can choose the most appropriate material to ensure a high-quality and cost-effective product.

Process

The process of customizing hardware display shelves involves several key steps. First, the design is created using computer-aided design (CAD) software, allowing for precise measurements and detailed designs. Next, the material is cut and shaped using CNC machining, laser cutting, or waterjet cutting techniques to create the individual components of the shelf. These components are then assembled using welding, bonding, or mechanical fasteners to create the final product. Quality control measures are taken throughout the process to ensure that each shelf meets the specified standards and requirements. Finally, the shelves are packaged and shipped to the customer, ready for installation and use.

Conclusion

Customizing hardware display shelves allows for the creation of unique and tailored products that meet the specific needs of a business or individual. By working closely with the client and understanding their requirements, manufacturers can create a product that not only meets their needs but also enhances their environment. The process of customization involves design, material, and process choices that ensure a high-quality and cost-effective product is created each time. Whether it’s a simple shelf for storing tools or a complex display system for showcasing products, customizing hardware display shelves can help to maximize impact and showcase products in the best possible way.

Articles related to the knowledge points of this article:

Wholesale Custom-made Boards and Hardware for Your Home

Title: Customized Metal Components: The Art of Crafting Perfectly Functional Hardware

Title: Special Prices on Custom Hardware in Yangzhou

Title: Customizing Hardware Intra-Pallet Trays in Hunan Province: A Comprehensive Guide