Custom Metal Stampings in Shantou: A Comprehensive Guide to High-Quality Sheetmetal Parts

Shantou is a city renowned for its custom metal stampings. These stampings are used to produce high-quality sheetmetal parts, which are used in various industries such as automotive, aerospace, and consumer goods. The process of creating these parts involves precision cutting, bending, and forming of metal sheets using specialized tools and equipment.The key to producing top-quality sheetmetal parts is the use of advanced technology and skilled craftsmen. Shantou has a long history of producing metal stamps and is known for its ability to create complex shapes and designs with precision.There are many factors to consider when choosing a custom metal stamping company in Shantou, including quality, cost, and delivery time. It is important to work with a company that has a reputation for producing consistent high-quality products while also providing competitive pricing.In conclusion, if you need high-quality sheetmetal parts for your business or project, Shantou is the place to go. With its rich history of custom metal stampings and skilled craftsmen, you can be confident that you will receive top-notch results.

Abstract: This guide explores the world of custom metal stampings in Shantou, focusing on the production process, materials, design considerations, and common applications. With a deep understanding of these aspects, businesses can make informed decisions when selecting a reliable supplier for their metal stamping needs.

Chapter 1: Introduction to Custom Metal Stampings in Shantou

1、1. Definition and Overview of Metal Stampings

Metal stampings refer to the process of shaping metal sheets into functional parts by pressing or molding them using specialized tools and equipment. The term "stamping" comes from the fact that the metal is pressed into its final shape, leaving behind a raised impression known as a die.

1、2. History and Evolution of Metal Stampings

The history of metal stampings dates back to ancient civilizations, where primitive tools were used to shape copper and bronze into jewelry and other artifacts. Modern metal stampings emerged in the early 20th century as a response to the growing demand for mass production of precision parts. Today, they are an integral part of many industrial sectors, including automotive, aerospace, electronics, and consumer goods.

1、3. Key Characteristics and Benefits of Metal Stampings

Some of the key characteristics and benefits of metal stampings include:

* High precision and accuracy due to the use of dies and precision machines

* Wide range of materials available, including steel, aluminum, titanium, and plastics

* Rapid production rates compared to other manufacturing processes

* Cost-effectiveness and scalability for small and large-scale production runs

* Environmentally friendly due to the use of recycled materials and energy-efficient equipment

1、4. Overview of Shantou's Metal Stamping Industry

Shantou, located in southeastern China, is a bustling city known for its vibrant trade culture and strong manufacturing sector. Its metal stamping industry has been thriving since the late 1980s, attracting both local and foreign investment. The city's proximity to major ports and transportation hubs has also contributed to its success as a distribution center for imported materials and finished products. In recent years, Shantou has been working to expand its expertise in high-tech industries such as robotics and automation, further enhancing its position as a leading manufacturer in China.

Chapter 2: Design Considerations for Custom Metal Stampings

2、1. Selection of Material Properties

When designing metal stamps, it is essential to consider the desired properties of the final product, such as strength, stiffness, corrosion resistance, and temperature tolerance. Factors like material cost, availability, and sustainability should also be weighed against these requirements to determine the most suitable material for the project. Common metals used in Shantou's metal stamping industry include stainless steel, carbon steel, aluminum alloys, and plastics.

2、2. Die Design and Setup

The die (or tool) is the primary factor influencing the quality and accuracy of the metal stamping process. A well-designed die can produce precise shapes with minimal waste or defects, while poorly made ones can result in inconsistent or damaged parts. Die design involves creating detailed drawings or models based on the required specifications, selecting appropriate tool materials and construction methods, and testing the die for proper fit and function before production begins. Setup procedures may also vary depending on the specific machine and application, but generally involve aligning the die with the sheet metal feedstock, adjusting pressure settings, and verifying dimensions before starting the press cycle.

2、3. Part Design Guidelines

In addition to considering material properties and die design, designers must also adhere to certain guidelines when creating metal stamping parts. These may include factors like surface finish, tolerances, drilling or perforation patterns, packaging instructions, and safety regulations. It is crucial to work closely with your supplier to ensure that all necessary information is conveyed effectively and that any special requirements are met during the manufacturing process.

Chapter 3: Common Applications of Custom Metal Stampings in Shantou

3、1. Automotive Industry

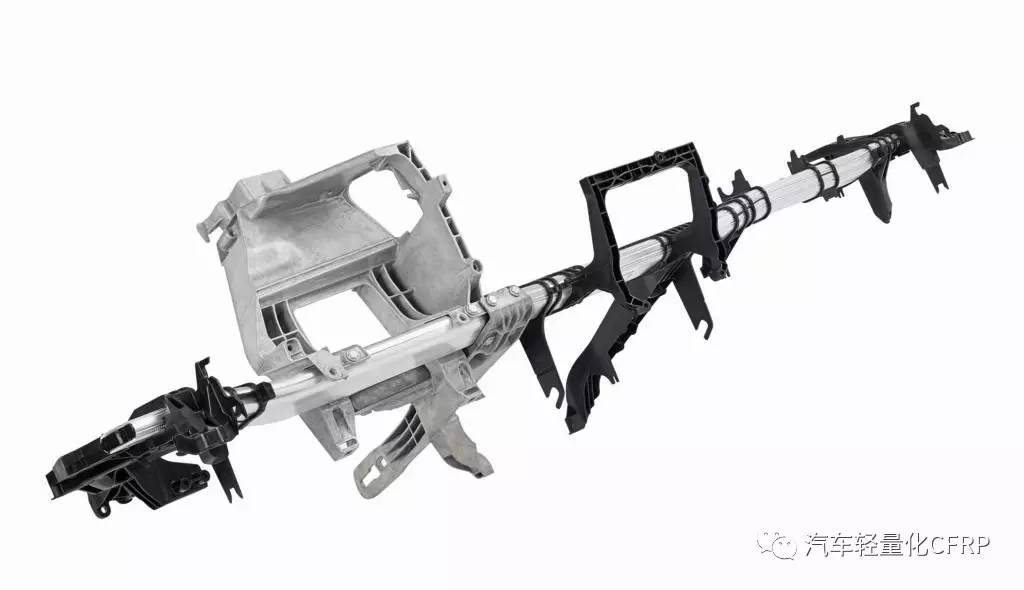

One of the main sectors where Shantou's metal stamping industry excels is the automotive industry, where precision components are needed for everything from engine blocks to door latches. Popular materials used in automotive stampings include stainless steel for high-temperature applications, carbon steel for lightweight components, and aluminum alloys for improved strength and fuel efficiency. Other applications in this field include gearboxes, steering columns, suspension systems, and electrical components.

3、2. Aerospace Industry

The aerospace industry requires high-quality metal stamping parts for aircraft structures, brackets, fasteners, and other mechanical components. Materials commonly used in aerospace stampings include titanium for lightweight and corrosion-resistant components, Inconel for extreme temperatures and pressures, and ductile iron for structural support beams. Other applications in this field include missile launch vehicles, space shuttles, and commercial airplane wings.

3、3. Electronics Industry

Electronic devices rely on precision metal stamping parts for various functions such as circuit boards, connectors, housings, and enclosures. Common materials used in electronic stamped parts include aluminum alloys for lightweight designs and improved heat dissipation, stainless steel for corrosion resistance in harsh environments, and plastic for non-metallic components like switches or buttons. Other applications in this field include computer peripherals, mobile phones, home appliances, and medical devices.

Articles related to the knowledge points of this article:

Smart Hardware for Customized Homes

Title: Customizing Metallic Components in Bengbu: The Ultimate Guide to Rubber Bending

Custom Hardware Manufacturers in Linyi

Custom Hardware Manufacturing in Chongqing: A Detailed Look into the Factory