Custom Large-Scale Metal Product Manufacturing: A Comprehensive Guide

Custom Large-Scale Metal Product Manufacturing is a comprehensive guide that covers everything you need to know about creating high-quality metal products on a large scale. From designing and engineering the product to sourcing raw materials and executing the manufacturing process, this guide provides step-by-step instructions for success. Whether you're a seasoned manufacturer or new to the industry, Custom Large-Scale Metal Product Manufacturing offers valuable insights and practical advice to help you achieve your goals. With its focus on efficiency, quality, and cost-effectiveness, this guide is essential for anyone looking to take their metal product manufacturing business to the next level. By following the guidelines outlined in this guide, you can streamline your operations, reduce waste, and maximize profitability. So if you're ready to take your manufacturing capabilities to the next level and compete in today's competitive market, don't miss out on Custom Large-Scale Metal Product Manufacturing – your ultimate guide to success!

In an increasingly competitive market, businesses are constantly seeking new ways to optimize their operations and stay ahead of the curve. One area where this is particularly true is in the realm of large-scale metal product manufacturing. Customizing large-scale metal products can be a challenging task, but with the right approach and a commitment to quality, it is possible to meet the unique needs of your customers and drive growth for your business. In this comprehensive guide, we'll explore the key considerations, strategies, and best practices for custom large-scale metal product manufacturing.

Large-Scale Metal Product Manufacturing: The Basics

Understanding Your Customer Needs: Before you begin the manufacturing process, it's crucial to have a clear understanding of your customer's needs and requirements. This may involve conducting thorough research, analyzing market trends, and developing detailed specifications for the final product. By doing so, you can ensure that your manufactured products meet the highest standards of quality and functionality.

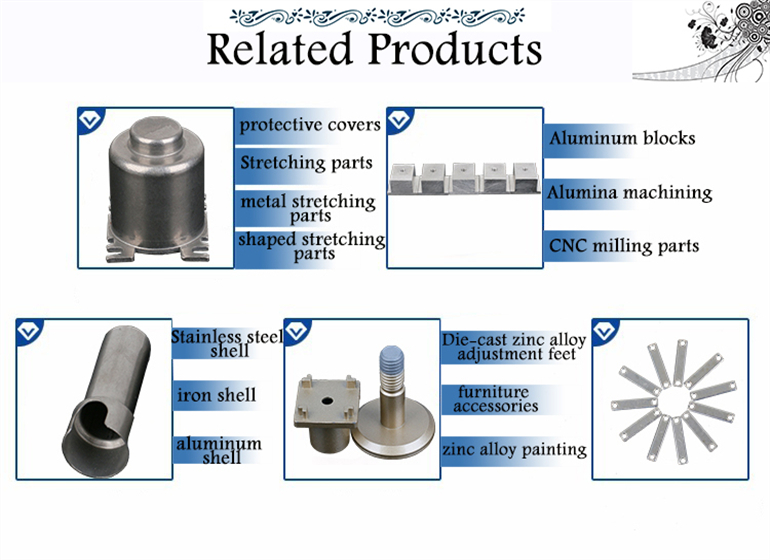

Selecting the Right Metal Type: There are countless metal types available for large-scale product manufacturing, each with its own unique properties and applications. Some of the most common types include aluminum, stainless steel, carbon steel, and titanium. When selecting a metal type, you'll need to consider factors such as strength, durability, corrosion resistance, cost, and availability.

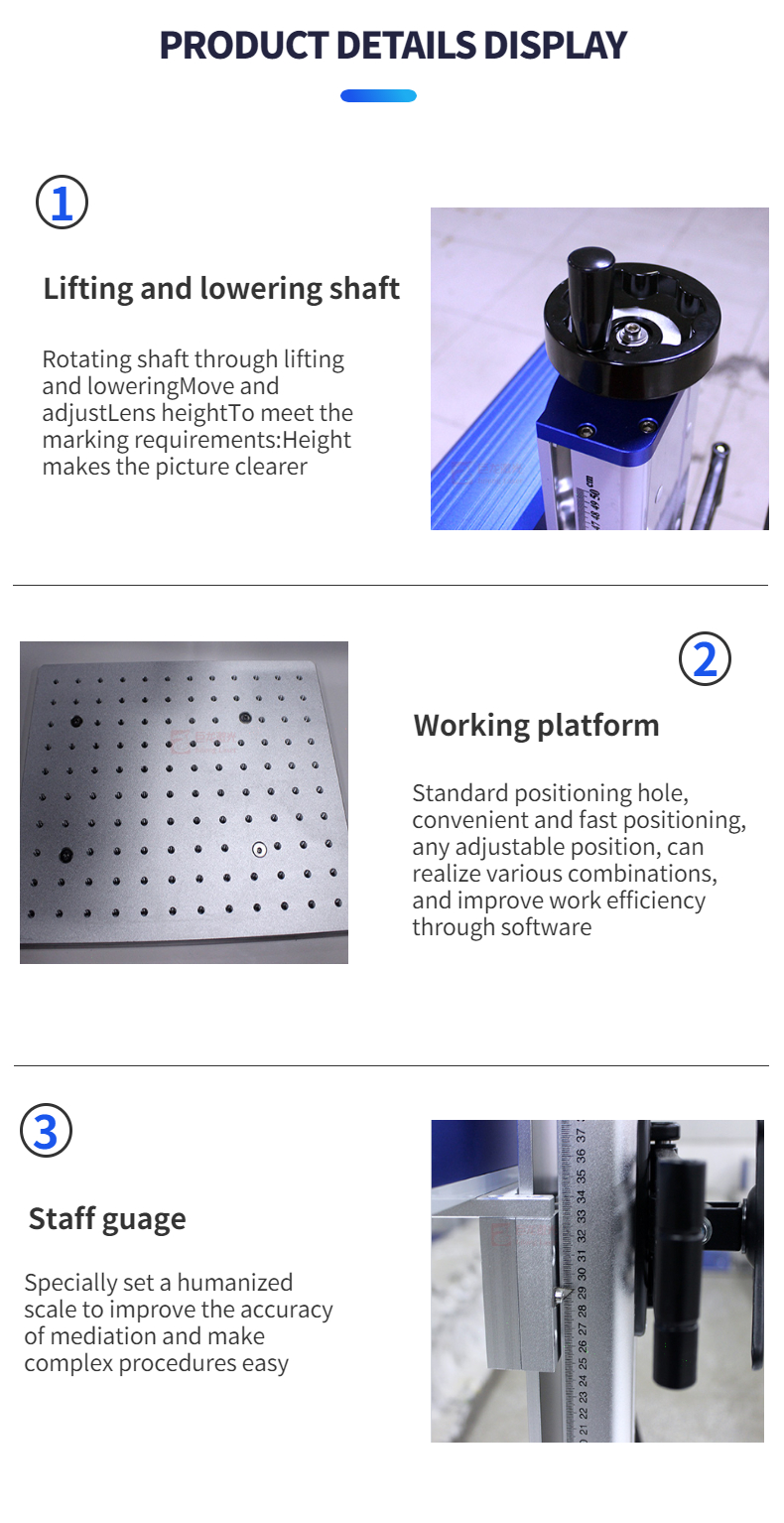

Designing for Manufacturability: The design of your metal products will play a critical role in the overall success of your manufacturing process. To ensure that your designs are manufacturable, it's essential to consider factors such as material flow, assembly methods, and surface finish. Additionally, you may want to work with a skilled engineer or designer to optimize your designs for efficiency and cost-effectiveness.

Establishing a Strong SupplyChain: Large-scale metal product manufacturing requires a robust supply chain to support the production process. This may involve sourcing raw materials from reliable suppliers, establishing partnerships with other manufacturers and distributors, and implementing effective inventory management systems.

The Benefits of Custom Large-Scale Metal Product Manufacturing

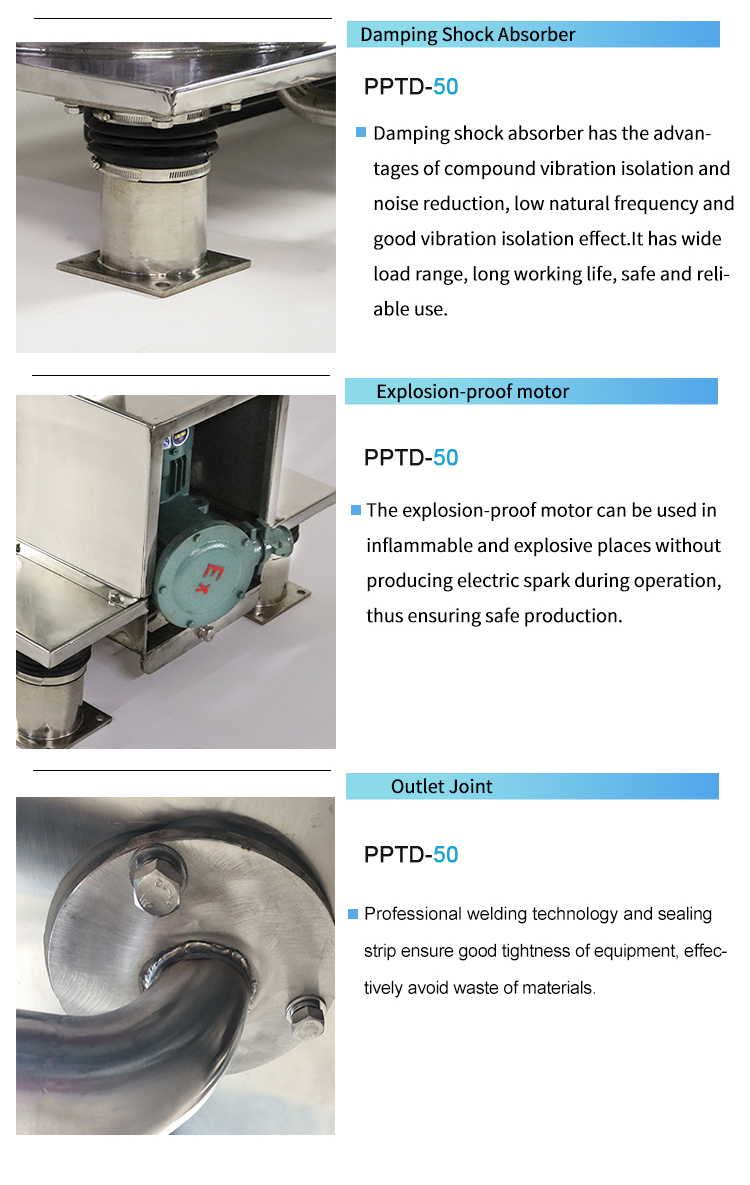

Enhanced Quality Control: Custom large-scale metal product manufacturing allows you greater control over the quality of your products. By working closely with your customers to develop accurate specifications and ensuring that your manufacturing processes are carefully monitored, you can minimize defects and ensure that your products meet their high expectations.

Increased Flexibility: Custom large-scale metal product manufacturing provides you with greater flexibility in terms of size, shape, and configuration. This allows you to cater to a wider range of customer needs and preferences, ultimately driving increased sales and revenue.

Competitive Advantage: By offering customized large-scale metal products, you can differentiate yourself from competitors and establish a strong reputation in the marketplace. This can lead to increased customer loyalty, repeat business, and referrals.

Strategies for Effective Custom Large-Scale Metal Product Manufacturing

Implement Lean Manufacturing Techniques: Lean manufacturing is a proven approach that helps businesses streamline their operations and improve efficiency. By implementing lean manufacturing techniques in your custom large-scale metal product manufacturing process, you can reduce waste, increase productivity, and improve overall profitability.

Utilize Advanced Technologies: Advanced technologies such as 3D printing, CNC machining

Articles related to the knowledge points of this article:

Rara Customized Hardware: Quality, Design, and Craftsmanship

Custom Hardware in Qingyuan: Quality and Versatility