Customizing Hardware Processes

Customizing Hardware Processes refers to the process of modifying or adjusting the hardware components of a device to meet specific needs or preferences. This process can involve changing the physical components of a device, such as adding or removing hardware modules, or adjusting the software that controls the hardware. Customizing Hardware Processes can result in a more personalized device that better suits the user's needs, but it can also lead to increased complexity and cost. Therefore, it is important to carefully consider the benefits and drawbacks of customizing hardware processes before proceeding with the modification.

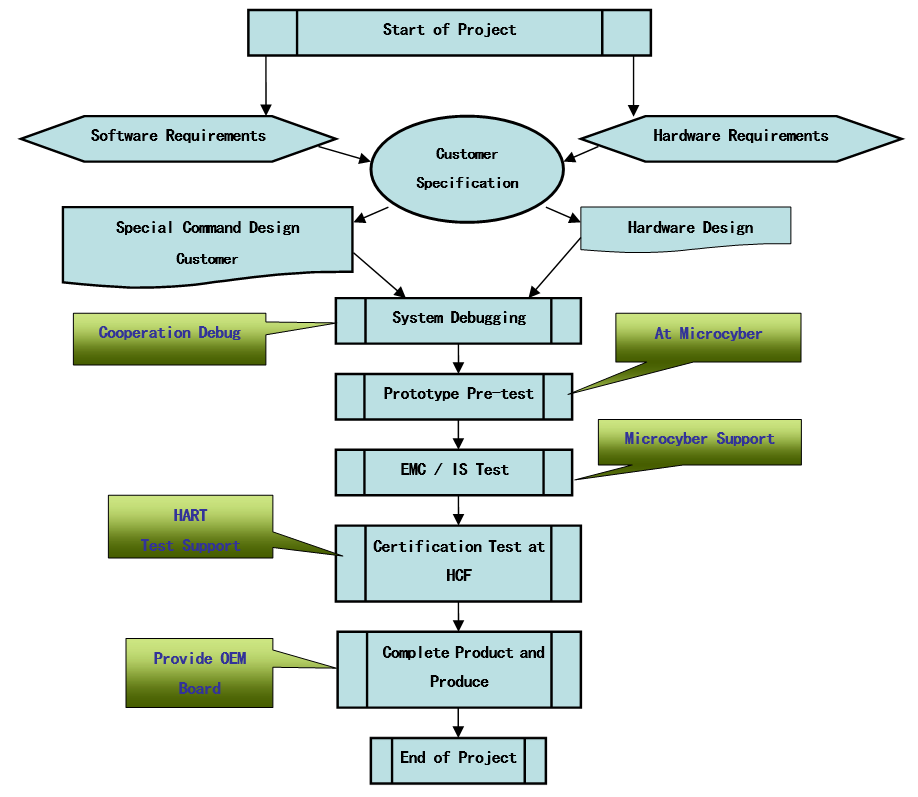

In the realm of hardware manufacturing, the process of customization has always been essential to meet the specific needs of customers. From a simple screwdriver to complex machinery, the steps involved in creating customized hardware products are numerous and require precision execution. This article outlines the key steps in a successful hardware customization process to help ensure that your products meet the requirements of your customers.

1、Understanding the Customer’s Needs

The first step in any customization process is to identify the specific needs of the customer. This includes understanding the type of hardware they require, the materials they prefer, and any other unique specifications they have. For instance, if a customer needs a screwdriver for a specific type of screw, you would need to identify that type of screw and ensure that the screwdriver is designed to match.

2、Designing the Custom Hardware

Once you have a clear understanding of the customer’s needs, you can move on to the design phase of the customization process. This involves creating a detailed design of the hardware product that will meet the customer’s requirements. The design should include the shape, size, and materials that will be used to manufacture the product. Additionally, any special features or specifications that need to be included should be noted at this stage.

3、Manufacturing the Custom Hardware

Once the design is complete, it is time to move on to the manufacturing phase of the customization process. This involves using various manufacturing techniques to create the physical product based on the design specifications provided. Common manufacturing techniques include machining, casting, molding, and cutting. Each technique has its own advantages and disadvantages, so it is essential to choose the right one based on the specific product being manufactured.

4、Quality Assurance and Testing

After the product has been manufactured, it is essential to perform quality assurance and testing to ensure that it meets the customer’s requirements and performs as expected. This may involve inspecting the product for defects or performing functional tests to ensure that it works correctly. If any issues are found during this stage, it may be necessary to make adjustments or remanufacture the product to correct them.

5、Packaging and Shipping

Once the product has passed quality assurance and testing, it is time to package and ship it to the customer. This involves preparing the product for transport by packaging it in a suitable container or wrapping it in protective material to ensure that it arrives safely and intact. Additionally, any necessary documentation or instructions for use should be included with the product at this stage.

In conclusion, customizing hardware processes is essential to meet the specific needs of customers and create products that are tailored to their requirements. By following the steps outlined above, you can ensure that your customization process is successful and that your customers are satisfied with the products you provide.

Articles related to the knowledge points of this article:

Title: Custom Manufacturing of Hardware Standards

CUSTOMIZED HARDWARE PACKAGE FOR YOUR HOME

Custom Cabinet Hardware: Included or Not?

Title: Shanghai Custom Cabinet Hardware Wholesale: The Ultimate Guide