Custom Metalworking Tool Adjustment Images: The Art and Science of Precision Engineering

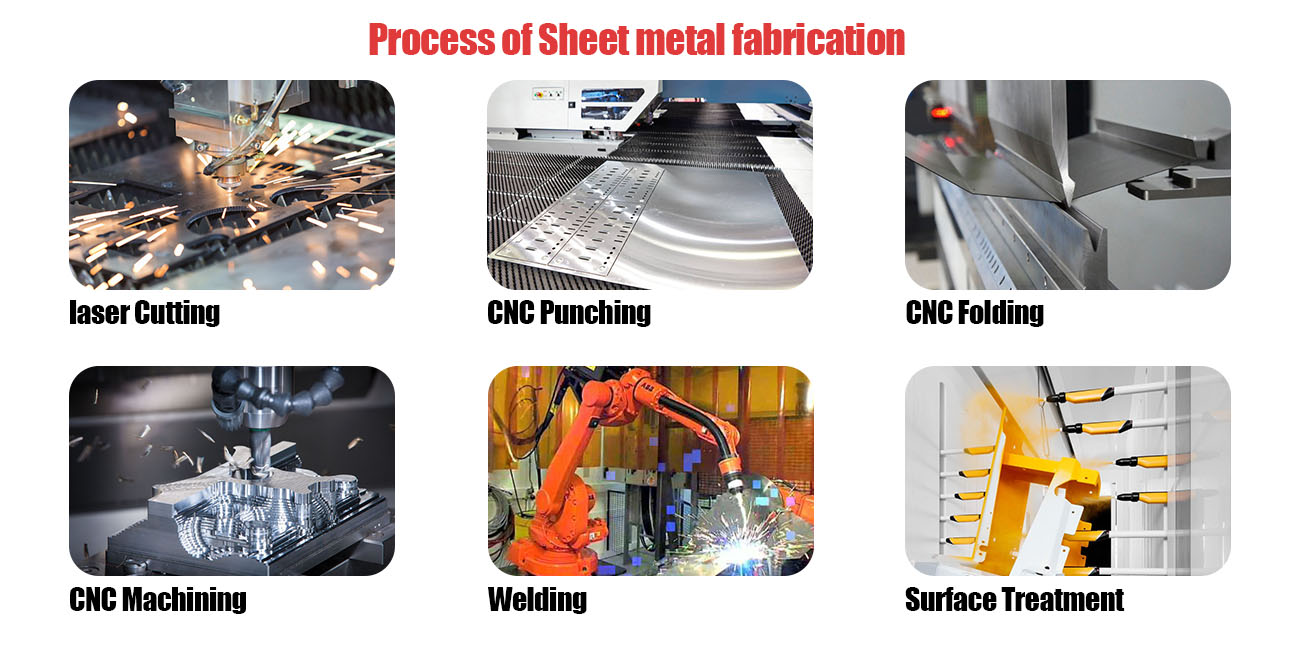

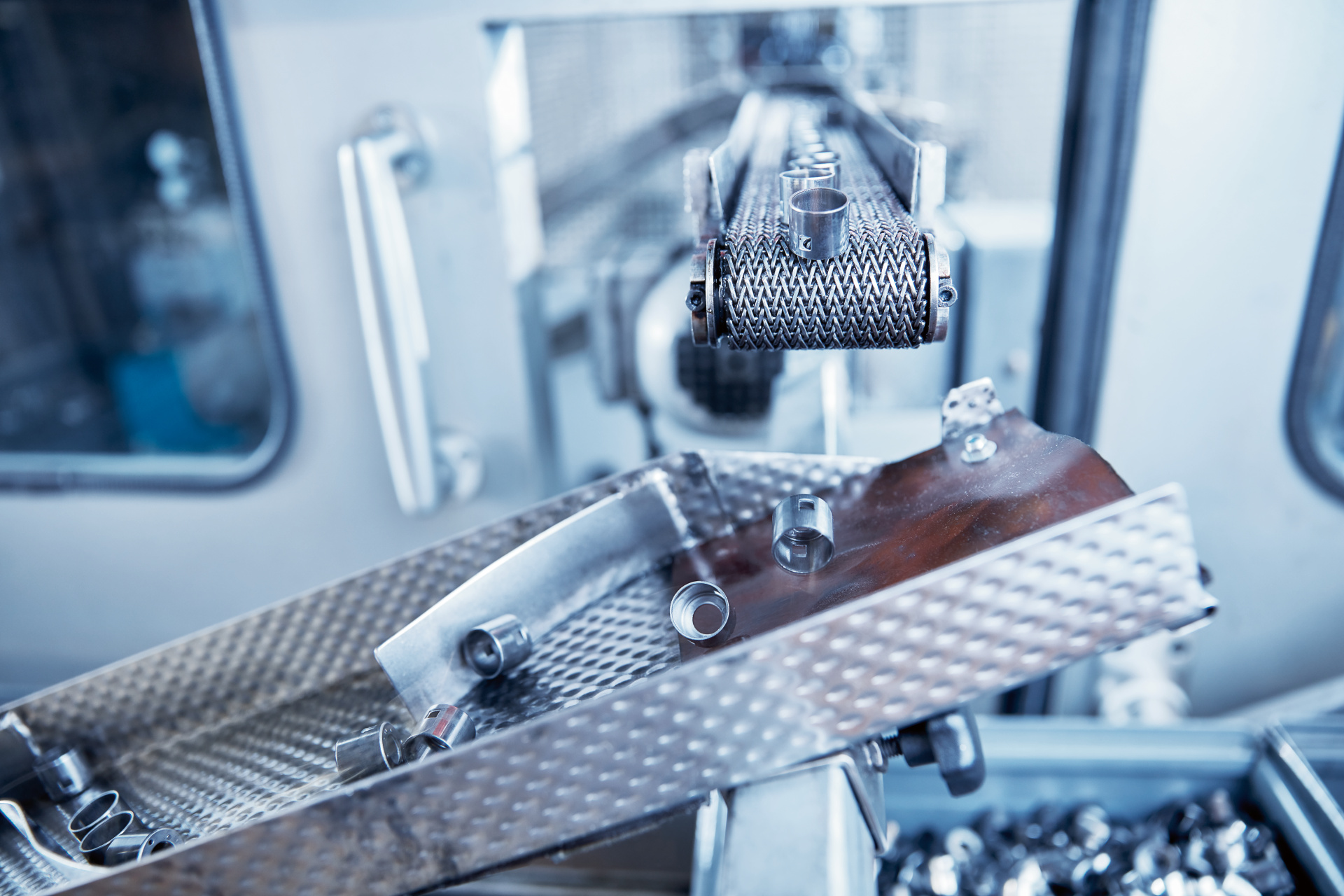

Custom metalworking tool adjustment images are an art form and science combined, requiring precision engineering to ensure accuracy and efficiency. The process of adjusting the tools used in custom metalworking involves a complex understanding of metallurgy, geometry, and physics. The images displayed in these adjustments showcase the intricate details involved in each step of the process, from measuring and marking the material to precisely aligning and adjusting the tool. These images demonstrate the importance of attention to detail and the need for specialized skills to achieve the desired results. By utilizing advanced technologies and techniques, custom metalworking can produce high-quality products that meet the unique needs of individual clients. The art and science of custom metalworking tool adjustment images is a testament to the ingenuity and creativity of engineers and technicians who dedicate themselves to this field.

Introduction:

In the world of advanced manufacturing, precision engineering plays a crucial role in ensuring the quality and reliability of products. One of the key elements of precision engineering is the use of custom metalworking tools, which are designed to meet the specific needs of individual projects. These tools require meticulous attention to detail, as well as the ability to accurately adjust them for optimal performance. This article will explore the art and science of custom metalworking tool adjustment images, providing an in-depth look at how they are created and used in precision engineering.

Section 1: The Importance of Custom Metalworking Tools

Custom metalworking tools are essential for achieving high levels of accuracy and efficiency in metalworking applications. They allow engineers and designers to create complex shapes and geometries that would be difficult or impossible to achieve with off-the-shelf components. By working closely with clients to understand their specific requirements, manufacturers can create custom tools that are tailored to their needs, resulting in improved product quality and faster production times.

However, the process of creating custom metalworking tools is not without its challenges. The first step is to develop a detailed design for the tool, taking into account factors such as material selection, cutting parameters, and end-user applications. Once the design has been finalized, it must be verified through rigorous testing and prototyping to ensure that it meets the required specifications and performance standards. This process can be time-consuming and expensive, requiring significant investment in research and development.

Section 2: The Art of Custom Metalworking Tool Design

The art of custom metalworking tool design lies in the ability to balance functionality, form, and cost-effectiveness. To achieve this balance, engineers must have a deep understanding of metalworking principles, as well as the latest technologies and materials available. They must also be able to work effectively with clients and other stakeholders to gather feedback and make iterative improvements to the design.

One key aspect of custom metalworking tool design is material selection. Different metals have different properties, such as strength, hardness, and corrosion resistance, which must be taken into account when choosing a material for a particular part or feature. Additionally, engineers may need to select materials based on factors such as weight, cost, and availability.

Another important consideration in custom metalworking tool design is cutting parameters. This includes factors such as feed rate, cutting depth, and tool path, which can have a significant impact on the quality and accuracy of the final product. Engineers must carefully balance these parameters to optimize performance while minimizing waste and potential damage to the machine or tool itself.

Section 3: The Science of Custom Metalworking Tool Adjustment Images

The science of custom metalworking tool adjustment images involves developing techniques for accurately measuring and adjusting the performance of tools in real-world situations. This requires a combination of technical expertise, mathematical modeling, and practical experience.

One common technique for measuring the performance of custom metalworking tools is using image processing algorithms. By capturing images of the tool during operation, engineers can analyze the geometry and texture of the resulting parts to determine factors such as edge roughness, material removal rate, and tool wear. This data can then be used to refine the tool's design or adjust its operating parameters as needed.

Another important aspect of custom metalworking tool adjustment images is understanding the underlying physics and mechanics of metalworking processes. This includes knowledge of factors such as pressure, temperature, friction, and energy transfer, which can all impact the performance of tools in different contexts. By incorporating this understanding into their designs and analyses, engineers can optimize the performance of their tools under a wide range of conditions.

Conclusion:

Custom metalworking tools are an essential component of precision engineering, enabling engineers and designers to create innovative solutions for a variety of complex problems. By combining art and science in their approach to tool design and adjustment, manufacturers can create custom tools that meet even the most demanding specifications while remaining cost-effective and efficient. As technology continues to evolve, it is likely that we will see further advancements in this field, leading to new opportunities for innovation and growth in the global precision engineering industry.

Articles related to the knowledge points of this article:

CUSTOM BIG HARDWARE: THE ULTIMATE GUIDE

Title: Crafting Custom Cabinet Hardware to Showcase Luxury and Precision

Custom Cabinet Hardware: A Comprehensive Guide

Title: Customizing Metallic Components in Bengbu: The Ultimate Guide to Rubber Bending