Customization of Metal Stampings in Guangzhou: A Comprehensive Guide

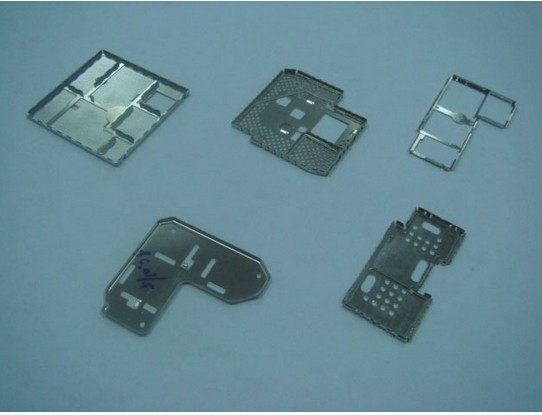

Metal stampings are widely used in a variety of manufacturing industries, including automotive, electronics, and aerospace. In Guangzhou, China, there are many experienced stamping manufacturers who offer customization services to meet the unique requirements of their clients. This comprehensive guide will provide an overview of the customization process for metal stampings in Guangzhou, including design, prototyping, production, and quality control. Design: The first step is to create a detailed design of the metal stamping that meets the specifications and requirements of the client. This includes selecting the appropriate material, size, shape, and features for the stamping. Prototyping: Once the design is finalized, a prototype can be created using various tools such as 3D printing or CNC machining. This allows the client to test and refine the design before production begins. Production: During the production stage, the stamping manufacturer will use advanced machinery and equipment to produce large quantities of stamped components quickly and efficiently. Quality control measures are implemented at every stage to ensure that the final product meets the required standards. In conclusion, customizing metal stampings in Guangzhou is a complex process that requires careful planning, design, prototyping, and production. By working with experienced manufacturers like those found in Guangzhou, businesses can achieve high-quality products that meet their specific needs and requirements.

Abstract:

Metal stampings, also known as metal pressings, are an essential component of various manufacturing processes. They are widely used in industries such as automotive, electronics, medical devices, and aerospace, among others. In Guangzhou, a city in southern China known for its thriving manufacturing sector, customization of metal stampings is a crucial aspect of the local industry. This article explores the process of customizing metal stampings in Guangzhou, including the types of materials used, design considerations, production methods, and quality control measures. It also discusses the benefits of working with a professional manufacturer in Guangzhou and provides some tips for selecting a reliable supplier.

Introduction:

The demand for metal stampings continues to grow globally, driven by advances in technology, increased automation, and the need for more efficient and cost-effective manufacturing solutions. Guangzhou, as one of the leading industrial hubs in China, has emerged as a key player in the global supply chain of metal stampings. With its advanced manufacturing facilities, skilled workforce, and competitive pricing, Guangzhou offers a range of customization options for manufacturers looking to produce high-quality metal stampings at a reasonable price.

Types of Materials Used for Customizing Metal Stampings:

When it comes to customization of metal stampings, the choice of material depends on the application requirements. Some of the most common materials used in metal stampings include aluminum, steel, iron, copper, and plastic. Each material has its unique properties, such as strength, durability, corrosion resistance, and heat resistance, which should be taken into account when selecting a suitable material for a particular application.

Design Considerations for Customizing Metal Stampings:

In order to produce high-quality metal stampings that meet customer requirements, careful design consideration is essential. The design should take into account factors such as part geometry, material properties, surface finish, and assembly requirements. Additionally, designers should consider the production feasibility of the design, including manufacturability issues such as tooling requirements and yield potential.

Production Methods for Customizing Metal Stampings:

There are several production methods available for customizing metal stampsings in Guangzhou, depending on the complexity of the part and the production volume. Some of the most common methods include traditional die-stamping, progressive die-stamping, transfer molding, and laser cutting. Each method has its advantages and disadvantages, and manufacturers should carefully evaluate their options based on factors such as part size, material thickness, and production speed.

Quality Control Measures for Customizing Metal Stampings:

Quality control is crucial to ensure that custom metal stamps meet specifications and deliver value to customers. In Guangzhou, many manufacturers implement rigorous quality control measures throughout the production process to ensure consistency and reliability. These measures may include visual inspections, dimensional checks, material tests, and surface finishes testing. Some suppliers may also employ independent third-party audits to verify their compliance with industry standards and quality management systems.

Benefits of Working with a Professional Manufacturer in Guangzhou:

Working with a professional manufacturer in Guangzhou can offer several benefits for businesses seeking to customize metal stamps. First and foremost, professional manufacturers have access to advanced manufacturing technologies and expertise that can help improve efficiency and quality. They also typically have established relationships with suppliers and logistics partners, which can streamline operations and reduce costs. Finally, they often offer flexible production schedules and quick response times, allowing businesses to quickly adapt to changing market conditions.

Tips for Selecting a Reliable Supplier in Guangzhou:

When selecting a supplier for custom metal stampings in Guangzhou, there are several factors to consider. First and foremost, businesses should conduct thorough due diligence on potential suppliers to assess their reputation, financial stability, and technical capabilities. They should also look for suppliers that offer transparent pricing structures and responsive communication channels. Finally, businesses should consider whether the supplier adheres to industry standards and regulatory requirements related to quality management and environmental protection.

Articles related to the knowledge points of this article:

Title: Customized Metal Hardware and Aluminum Components in Kunming: A Comprehensive Guide

Custom Metal Stretching Factory