The Art of CNC Machining in Metalworking: A Comprehensive Guide for Hardware Manufacturers

CNC machining, or computer numerical control machining, has revolutionized the metalworking industry. It offers a precise and efficient method for cutting and shaping metals, making it an essential skill for hardware manufacturers. This comprehensive guide provides an in-depth analysis of the art of CNC machining in metalworking. It covers the basics of CNC machines, such as their components and functions, and how to operate them effectively. Additionally, it delves into the advanced techniques used in CNC machining, including 5-axis machining, multi-tasking, and high-speed cutting. The guide also explores the importance of tool selection and maintenance, as well as the significance of software and programming in CNC machining. By understanding the principles and practices of CNC machining, hardware manufacturers can improve their productivity, quality, and competitiveness in the market. This guide is an invaluable resource for any aspiring or seasoned CNC machinist looking to expand their knowledge and skills in this exciting field.

Introduction

In this era of rapid technological advancement, precision engineering and cutting-edge manufacturing techniques have become the cornerstone of success in various industries. One such industry that has witnessed a significant transformation over the years is metalworking, particularly the field of hardware manufacturing. With the advent of computer numerical control (CNC) machine tools, or commonly referred to as CNC machines, the process of manufacturing metal components has been revolutionized. This article aims to provide an in-depth understanding of CNC machine tools and their applications in the hardware manufacturing sector, specifically focusing on how CNC machining can be employed by hardware manufacturers to produce high-quality products efficiently and cost-effectively.

Understanding CNC Machines and Their Applications in Metalworking

Computer numerical control (CNC) machine tools are advanced mechanical devices that are designed to execute precise and repetitive tasks using computerized instructions. These machines use a combination of computer programs and mechanical components to convert digital data into physical actions, thereby allowing for highly accurate and efficient machining of various metal components. In the context of hardware manufacturing, CNC machines are widely used to produce complex shapes, patterns, and designs in metals such as aluminum, steel, titanium, and other alloys. Some of the key benefits of CNC machines in metalworking include:

1、High Precision: CNC machines offer unparalleled precision when it comes to machining metal components. By utilizing a combination of software algorithms and mechanical components, these machines can produce components with extremely tight tolerances, ensuring that the final product meets or exceeds customer expectations.

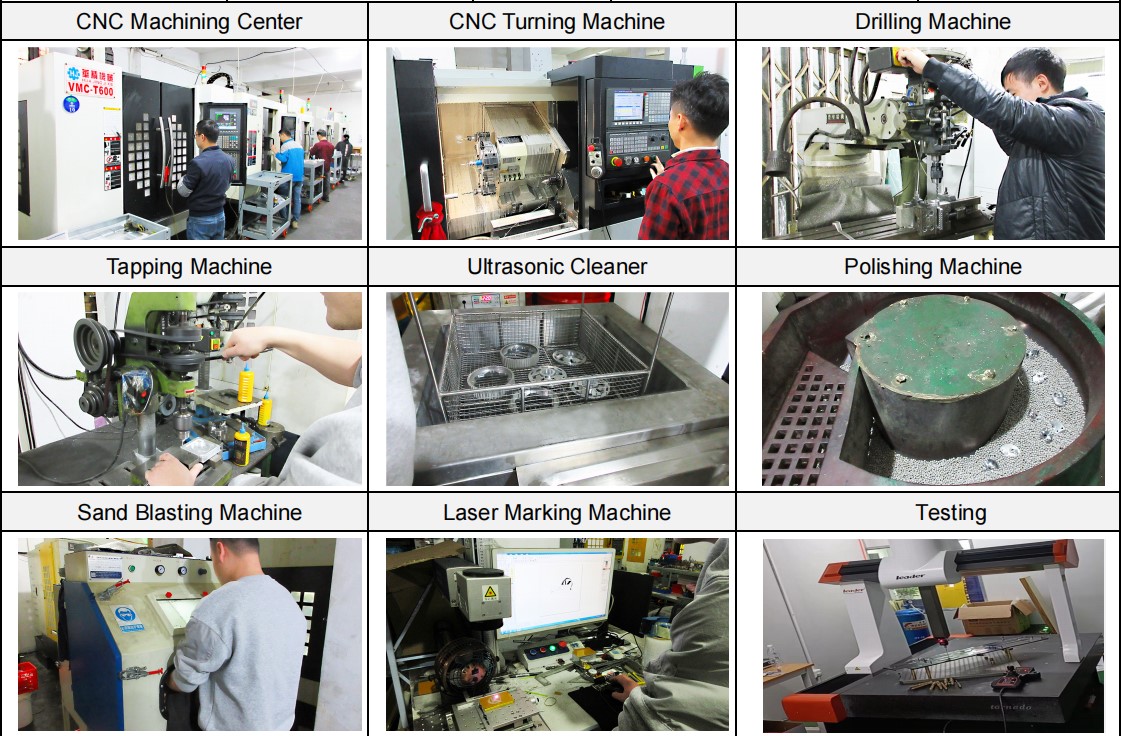

2、Versatility: CNC machines are capable of performing a wide range of machining operations on different types of metals. They can be programmed to perform tasks such as milling, drilling, tapping, grinding, broaching, and more, making them ideal for a diverse range of metalworking applications.

3、High Efficiency: By automating many of the tedious and time-consuming tasks associated with traditional metalworking methods, CNC machines can significantly improve efficiency in the manufacturing process. This translates into reduced production times, lower labor costs, and improved overall productivity.

4、Cost-Effective: While CNC machines may require a significant initial investment, they offer long-term cost savings by reducing the need for skilled labor, minimizing waste, and improving overall efficiency in the manufacturing process. This makes them an attractive choice for hardware manufacturers looking to streamline their operations and stay competitive in the market.

How CNC Machining Can Benefit Hardware Manufacturers

There are numerous ways in which CNC machining can benefit hardware manufacturers in terms of quality, efficiency, and profitability. Some of these benefits include:

1、Improved Product Quality: As mentioned earlier, CNC machines offer high precision when it comes to machining metal components. This translates into better-quality products that meet or exceed customer expectations. By using CNC machines to manufacture their hardware components, manufacturers can ensure that their products are consistent in terms of dimensions, tolerances, and other critical features.

2、Faster Production Times: Since CNC machines automate many of the repetitive tasks associated with traditional metalworking methods, they can significantly speed up the production process. This means that hardware manufacturers can produce more products in less time, leading to increased revenue and profitability.

3、Reduced Labor Costs: By automating many of the tasks involved in metalworking, CNC machines help to reduce the need for skilled labor. This can lead to lower labor costs for manufacturers, further improving their profitability.

4、Increased Customization Options: With CNC machines able to perform a wide range of machining operations on different types of metals, hardware manufacturers can create highly customized products to meet specific customer requirements. This allows them to stand out in the market and attract customers who are looking for unique and tailored solutions.

5、Reduced Waste: By using CNC machines to manufacture their hardware components, manufacturers can minimize waste by producing parts that are precise and accurately sized. This helps to reduce material consumption and lower environmental impact compared to traditional manual manufacturing methods.

Conclusion

In conclusion, CNC machining is a powerful tool that can significantly benefit hardware manufacturers in various aspects of their operations. From improving product quality and efficiency to reducing labor costs and waste, these benefits make CNC machines an essential investment for any manufacturer looking to stay competitive in the market. As technology continues to advance at an exponential pace, it is crucial for hardware manufacturers to embrace new technologies like CNC machines to remain relevant and profitable in today's fast-paced business environment.

Articles related to the knowledge points of this article:

Jinli Hardware Manufacturer: Quality and Innovation

AN HUI INVENTORY HARDWARE MANUFACTURER

Dandong Formal Hardware Manufacturers: Location and More

Title: Effective Strategies for Promoting and Operating Hardware Manufacturers