Custom Strong Magnets in Humen: A Comprehensive Guide to Quality and Customization

Humen, a city in central China's Hubei Province, has long been known for its strong magnets. These custom-made magnets are of exceptional quality and can be tailored to meet the specific needs of various industries. From automotive components to medical devices, Humen's magnets have found widespread use around the world due to their reliability and durability. The process of producing these magnets involves careful selection of raw materials, precision manufacturing techniques, and strict quality control measures. This ensures that every magnet meets the highest standards of performance and durability. To ensure maximum customization, customers can work closely with Humen's experienced engineers and designers to design and create magnets that suit their specific requirements. With a commitment to excellence and customer satisfaction, Humen's magnets continue to be a trusted source of high-quality custom magnets worldwide. Whether you need large or small, strong or weak, Humen's expert team is ready to provide you with the perfect magnet solution. So why wait? Contact us today to learn more about how we can help you meet your custom magnet needs!

In the bustling city of Humen, located in the eastern province of Guangdong, China, lies a hidden gem that boasts a history spanning over two centuries. This gem is none other than the renowned虎门五金城, a hub of industrial activity and a testament to China's manufacturing prowess. Within this dynamic community, one can find an abundance of specialized suppliers offering a wide range of products and services, including but not limited to, the production of custom-made strong magnets.

Strong magnets, also known as magnetic materials, are essential components in many modern industries, such as electronics, automotive, aerospace, and construction. They play a crucial role in various applications ranging from data storage and retrieval to power generation and transportation. The demand for these materials continues to grow as technological advancements drive innovation and increase efficiency.

Humen's position as a major center for industrial production makes it an ideal place for businesses seeking to source high-quality magnetic materials at competitive prices. One such supplier that has gained a reputation for providing top-notch custom magnetic solutions is [Supplier's Name]. This article aims to provide an overview of the process involved in creating custom strong magnets in Humen and highlight some key considerations when selecting a provider.

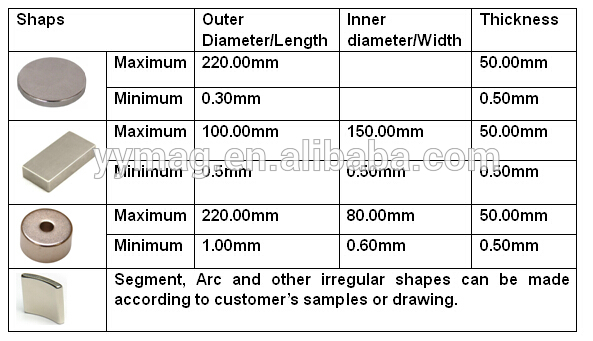

The first step in designing custom strong magnets is to determine the specific requirements of the application. Factors such as the required strength, size, shape, and material type (e.g. ferrite or neodymium) need to be carefully considered. Once these parameters are established, a supplier can work with customers to develop a customized solution that meets their needs.

One popular option for custom strong magnets is the use of ferrite magnets. These materials are made from iron oxide and have excellent magnetic properties, making them suitable for a wide range of applications. Ferrite magnets can be designed with various shapes and sizes, depending on the specific requirements of the project. Some common shapes include squares, cylinders, and bars. Additionally, ferrite magnets can be coated with different materials to enhance their performance or protect against environmental factors such as moisture and temperature fluctuations.

Another option for custom strong magnets is neodymium magnets. These materials are derived from rare earth elements and offer higher magnetic strengths compared to ferrite magnets. Neodymium magnets are often used in high-strength applications where precision and consistency are critical. They can also be shaped into complex structures such as rings, pins, and spheres. However, due to their higher cost compared to ferrite magnets, neodymium magnets may not be suitable for all projects.

When selecting a supplier for custom strong magnets in Humen, several factors should be considered. First and foremost, it is essential to choose a provider with a proven track record of producing high-quality products that meet customer needs. This can be achieved by reviewing customer feedback, conducting quality control checks, and obtaining certifications such as ISO or CE standards. In addition, it is important to ensure that the supplier has access to advanced manufacturing equipment and technologies to produce custom solutions efficiently and accurately. Furthermore, having a reliable supply chain with flexible delivery options is crucial for ensuring timely delivery and reducing costs associated with inventory holding and shipping.

Once you have identified a suitable supplier, the design phase can begin. This includes creating detailed drawings and specifications outlining the required dimensions, shape, and material type of the magnets. The supplier will then review these specifications to confirm that they can fulfill the order. If necessary, adjustments may be made based on technical considerations or customer feedback. After finalizing the design, the supplier will produce samples for testing and validation before proceeding with mass production.

During mass production, it is essential to ensure that the quality standards are maintained throughout the process. The supplier should have robust quality control measures in place, including regular inspections at every stage of production to identify any issues early on. Additionally, maintaining accurate records of each batch produced can help identify any potential quality issues and facilitate remediation if necessary. Finally, it is crucial to monitor the performance of the final product closely to ensure that it meets the specified requirements and performs optimally in the intended application.

In conclusion, custom strong magnets offer a versatile solution for a wide range of applications in industries such as electronics, automotive, aerospace, and construction. By working with a reliable supplier in Humen that offers high-quality products and efficient customization services, businesses can achieve their goals while minimizing costs and maximizing efficiency. When designing custom strong magnets in Humen, it is essential to consider factors such as material type, shape, size, strength requirements, and performance expectations. By taking these factors into account and choosing a supplier with a proven track record of success, businesses can create effective custom solutions that meet their unique needs.

Articles related to the knowledge points of this article:

The rise of customized hardware in whole-home decoration: a new trend in interior design

Title: Customization of Metal Engraving Services in Zhejiang Province

Custom Function Hardware for an Entire House: Pictures and More

Custom Metal Packaging Bags: The Ultimate Solution for Product Protection and Branding