Customizing Automotive and Hardware Parts

The automotive and hardware parts industry is booming, offering a wide range of products tailored to meet the diverse needs of consumers. From engines to interior components, and from tools to appliances, these parts are designed to enhance the performance and appearance of vehicles and houses. By carefully selecting high-quality materials and implementing advanced manufacturing techniques, these parts are able to withstand the rigors of daily use while providing a customized fit for each application. Whether it's upgrading an engine or adding a unique touch to a house, these customized parts are essential for making vehicles and houses stand out from the crowd.

In today's global market, the demand for customized automotive and hardware parts has skyrocketed. From car engines to interior components, to tools and fasteners, the industry has seen significant growth in the customization of these parts to meet the diverse needs of customers.

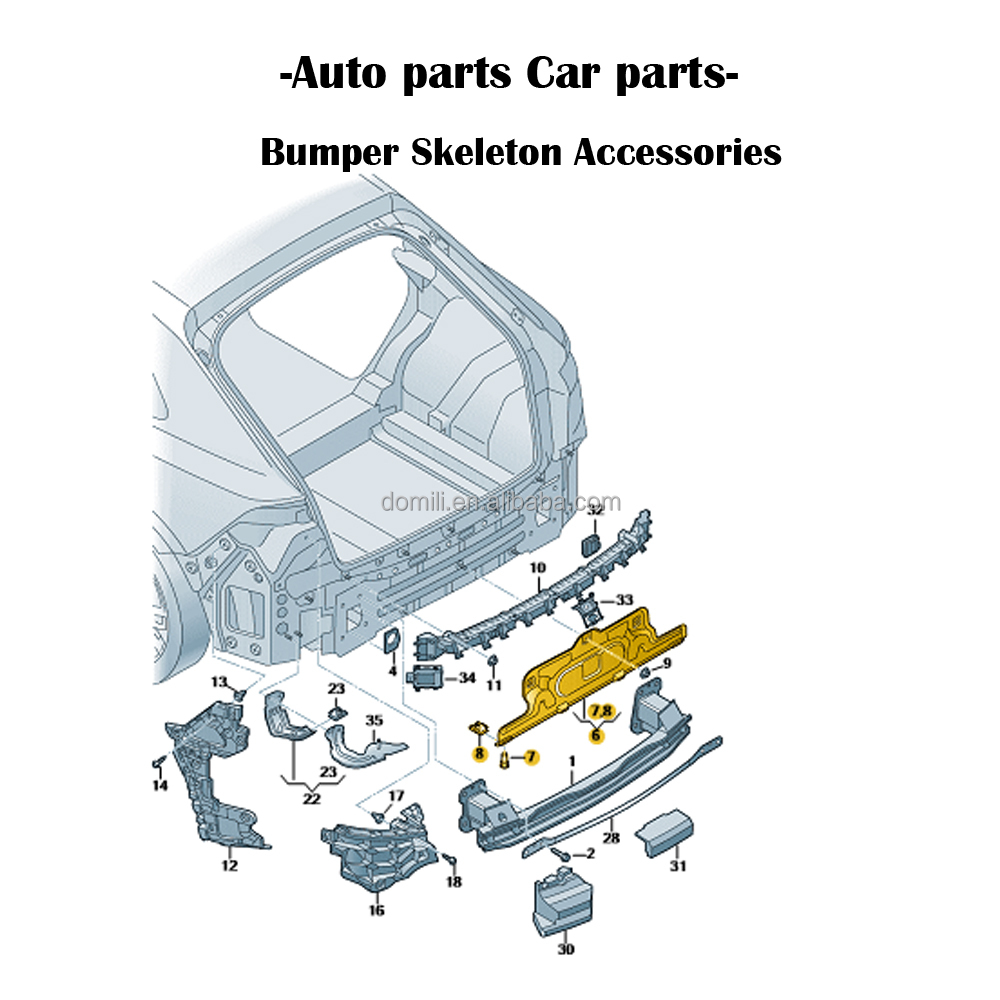

The automotive industry is one of the largest beneficiaries of customized parts. From car manufacturers to repair shops, the demand for tailored components has increased significantly. Car manufacturers often need customized parts to create unique designs or to accommodate specific customer requests. For instance, some car models may require specialized engines, transmission systems, or interior components to stand out from the competition.

On the other hand, hardware parts customization has also gained popularity in recent years. From tools to fasteners, these components are often tailored to meet the specific needs of a project or customer. For instance, a tool manufacturer may create a specialized tool that can only be used for a specific task or application. This ensures that the tool is optimized for its intended purpose, increasing its efficiency and durability.

The process of customizing these parts often involves a series of steps that ensure the final product meets the desired specifications and standards. From designing the part to selecting the right materials and manufacturing techniques, each step is crucial to ensure the final product is of high quality and performance.

Moreover, the cost-effectiveness of customized parts has also made them more appealing to businesses and individuals. By creating tailored components, manufacturers can often achieve significant cost savings compared to purchasing off-the-shelf parts. This is because customized parts are designed specifically for a particular application or project, reducing the need for additional modifications or adjustments.

However, it is important to note that while customized parts may offer numerous advantages, they also present some challenges. For instance, the manufacturing process may be more complex and time-consuming compared to producing standard parts. Additionally, there may be fewer suppliers available for customized parts, making it more difficult to source these components quickly or affordably.

In conclusion, customizing automotive and hardware parts has become an integral part of today's global market. By creating tailored components that meet the specific needs of customers or projects, manufacturers can achieve significant cost savings and improve overall efficiency and performance. However, it is important to carefully consider the challenges associated with customization to ensure the final product is of high quality and meets the desired standards.

Articles related to the knowledge points of this article:

Custom Hardware Showcase: A Comprehensive Guide to Displaying your Product Line

Sheet Metal Hardware Custom Shop

Title: Innovative Solutions from Shandong Factory for Metal Hardware customization

Title: Customizing Hardware for Reliable and Durable Baggage in Xiamen

Title: Crafting Custom Metalworking Ovens in Gansu: A Comprehensive Guide

Title: Crafting Custom Hardware Components in Wenzhou: A Masterclass in Quality and Style