Customized Metal Sliding Tracks: Design, Production, and Application

Customized Metal Sliding Tracks: Design, Production, and ApplicationIn the modern industrial and manufacturing sectors, customized metal sliding tracks have become a crucial aspect of material handling and storage solutions. These tracks, which are designed and produced to meet specific application requirements, enable efficient and cost-effective movement of materials from one point to another.The design of customized metal sliding tracks involves consideration of several factors such as the type of material to be moved, the frequency of movement, and the environmental conditions in which the tracks will be used. The production process typically involves machining, bending, and welding processes to create the desired track shape and dimensions.The application of customized metal sliding tracks is wide-ranging and can be found in industries such as automotive, aerospace, and healthcare. In the automotive industry, these tracks are used to move components and assemblies from one station to another during the manufacturing process. In healthcare, they are employed to transport medical supplies and equipment.Overall, customized metal sliding tracks play a crucial role in improving the efficiency and productivity of modern industrial and manufacturing operations. By designing and producing these tracks to meet specific application needs, companies can ensure that their material handling and storage solutions are optimized for their unique operations.

Metal sliding tracks, also known as sliders or drawers, are a crucial component of many industrial and consumer products. These tracks enable smooth movement of drawers or doors in cabinets, desks, and other furniture pieces. While standard metal sliding tracks are available in the market, customized ones are often needed to meet specific application requirements. This article discusses the design, production, and application of customized metal sliding tracks.

Design of Customized Metal Sliding Tracks

The design of customized metal sliding tracks begins with understanding the specific needs of the application. This includes the size, shape, and performance requirements of the tracks. For instance, in a drawer system, the design may need to accommodate different drawer sizes, shapes, and load capacities. The design also needs to consider the operating environment, such as temperature, humidity, and other factors that may affect the performance of the tracks.

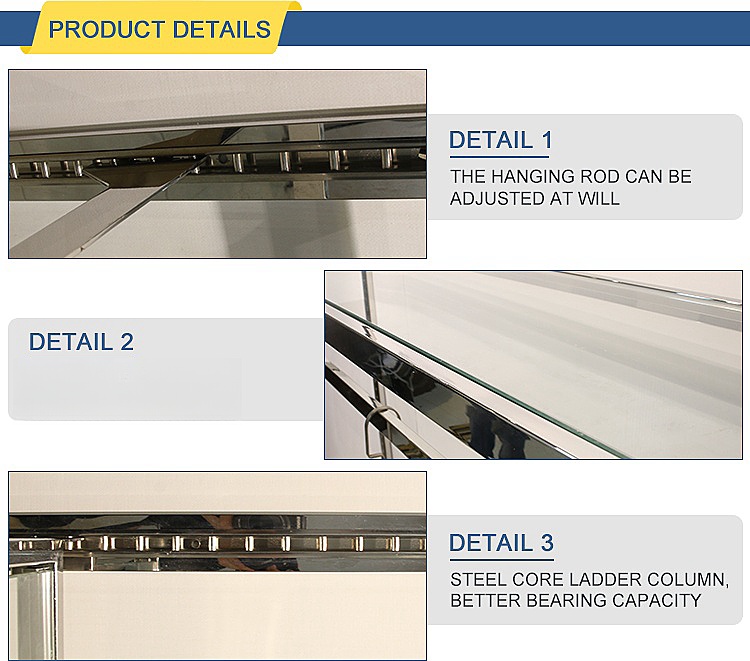

Once the design requirements are clear, the next step is to create a detailed design using computer-aided design (CAD) software. This ensures precise measurement and optimization of the track design to meet the specified performance standards. The design may also include features like bearings, rollers, or ball bearings to enhance the smoothness of movement or increase load capacity.

Production of Customized Metal Sliding Tracks

The production process for customized metal sliding tracks typically involves metal cutting, machining, and assembly operations. High-precision cutting tools are used to cut the metal stock into the desired shape and size. Machining processes like milling, drilling, and tapping are then used to create the final product with desired features and dimensions. Quality control measures are taken to ensure that each track meets the specified standards before it is packaged and shipped to the customer.

Application of Customized Metal Sliding Tracks

Customized metal sliding tracks find applications in various industries and consumer products. In the furniture industry, they are used in drawers, cabinets, and other storage solutions to enable smooth drawer movement and increase load capacity. In the automotive industry, they are used in car doors, windows, and sunroofs to provide smooth operation and increased durability. In the electronics industry, they are used in TVs, computers, and other devices to enable easy access to internal components while maintaining structural integrity.

Customized metal sliding tracks also have numerous applications in medical equipment, aerospace components, and other high-performance industries where precision and reliability are crucial. These tracks are designed to meet specific performance requirements and often require unique materials and finishes to ensure compatibility with the application environment.

In conclusion, customized metal sliding tracks play a crucial role in various industries and consumer products by providing smooth movement, increased load capacity, and structural integrity. The design, production, and application of these tracks require a high level of precision and reliability to ensure they meet the specific needs of each application. By understanding these requirements and using advanced design and production techniques, customized metal sliding tracks can be created to enhance the performance and usability of any product.

Articles related to the knowledge points of this article:

Custom Layered Board Hardware: The Key to Effective and Efficient Design

Title: Custom Layered Boards and Hardware for Your Home

Precision Hardware Fitting Custom Processing: Quality and Precision at Its Best

Customizing Hebei Hardware Sheet Metal Parts

Title: How Much Hardware is Required for Customized Cabinets?