Custom CNC Machining Services for Automotive Fuel Lines and Pipes

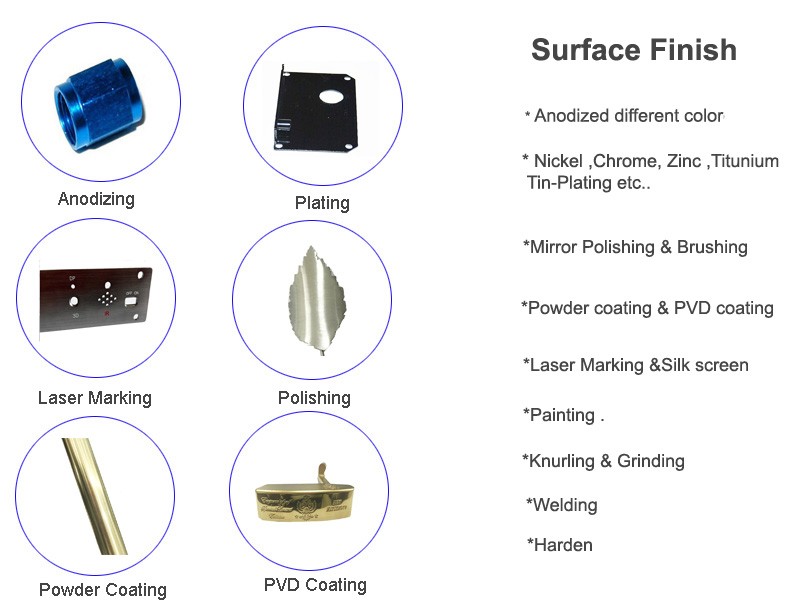

As the automotive industry continues to evolve, custom CNC machining services are becoming increasingly important for producing high-quality fuel lines and pipes. At our company, we specialize in providing these services to meet the demanding needs of automotive manufacturers. With advanced technology and a team of experienced engineers, we are able to produce precise and durable fuel line and pipe components that meet or exceed industry standards. Whether you need standard or specialty components, we have the expertise to deliver customized solutions that meet your specific requirements. Our process involves computer-aided design (CAD), programming, and cutting using state-of-the-art CNC machines. We use only high-grade materials such as stainless steel, aluminum, and PVC to ensure long-lasting performance. We also offer value-added services such as welding and finishing to further enhance the durability and functionality of your fuel system components. Our commitment to quality, precision, and customer satisfaction makes us the go-to source for custom CNC machining services for automotive fuel lines and pipes. Contact us today to learn more about our services and how we can help you meet your manufacturing needs.

In the ever-evolving world of automotive manufacturing, precision and efficiency are key factors in achieving success. This is why many companies are turning to custom CNC machining services to produce high-quality automotive fuel lines and pipes that meet their specific needs. At our company, we specialize in providing such services, utilizing state-of-the-art CNC machinery and skilled technicians to deliver exceptional results. In this article, we will explore the benefits of CNC machining for automotive fuel lines and pipes, as well as some of the unique features that set our custom services apart from the competition.

CNC machining, or computer numerical control machining, is a subtractive manufacturing process that utilizes computerized software to control cutting tools and produce complex shapes and patterns on metal materials. This advanced technology offers several advantages over traditional machining methods, including higher precision, faster production times, and greater consistency in quality. When it comes to producing automotive fuel lines and pipes, CNC machining allows manufacturers to create components that are both precise and durable, ensuring reliable performance under heavy use and harsh environments.

One of the primary benefits of using CNC machining for automotive fuel lines and pipes is its ability to produce components with exceptional accuracy. By programming the CNC machine to follow a precise design blueprint, manufacturers can ensure that each component meets exact specifications, minimizing the risk of errors and defects. This level of accuracy is particularly important in applications where even the smallest differences in dimension can have a significant impact on performance, such as in fuel system components that require tight clearances between components. Furthermore, by controlling the speed and feedrate of cutting tools during the machining process, CNC machines can produce components with highly uniform surfaces, further improving the overall quality and reliability of the final product.

In addition to accuracy, CNC machining also offers significant improvements in production time compared to traditional machining methods. With automated machines that can work around the clock without breaks, CNC machining enables manufacturers to produce large volumes of parts quickly and efficiently. This is particularly beneficial for companies that need to keep up with rapidly changing market demands or for organizations that operate in high-volume manufacturing settings. By leveraging the power of CNC technology, manufacturers can significantly reduce their production costs while still delivering high-quality components on time.

Another key advantage of using CNC machining for automotive fuel lines and pipes is its ability to maintain consistent quality throughout the production process. Because CNC machines are programmed to follow a precise set of instructions, they can produce components with consistent dimensions, angles, and other attributes. This eliminates the risk of variations in quality that can arise from manual labor or other human error sources. Moreover, by using computer-controlled machines, manufacturers can detect and correct defects early in the process, ensuring that only top-quality components leave the shop. This level of quality control is essential for industries where safety and reliability are paramount, such as automotive manufacturing.

At our company, we take pride in offering custom CNC machining services that meet the unique needs of our clients. Whether you require standard fuel line and pipe components or specialized designs that require additional engineering support, our team has the expertise and resources to deliver high-quality results. Our state-of-the-art CNC machines are equipped with advanced sensors and software that enable us to produce components with exceptional accuracy and precision. Additionally, our skilled technicians employ strict quality control measures throughout the production process to ensure that each component meets our high standards. We offer fast turnaround times, competitive pricing, and excellent customer service to ensure your complete satisfaction with our products.

In summary, CNC machining is a powerful tool that can greatly enhance the efficiency and quality of automotive fuel line and pipe manufacturing. By utilizing advanced technology and skilled technicians, companies can produce components with exceptional accuracy, speed, and consistency while maintaining high levels of quality. At our company, we specialize in providingcustom CNC machining services that meet your unique needs, helping you stay ahead of the competition and drive your business forward. So why wait? Contact us today to learn more about how we can help you achieve your goals with precision CNC machining!

Articles related to the knowledge points of this article:

American Nanz Hardware Customization

Custom Hardware Charging in Beijing

Custom Hardware in Stock in Wuxi

Title: Custom Metallurgical Grinding Tools Manufacturers in Minhang District, China

Title: Customize Your Lv Hardware to Perfection: A Guide to Crafting Stunning Lv Accessories