Exploring the World of Hardware Wholesale Valves: A Comprehensive Guide

Hardware wholesale valves are essential components in various industries, including plumbing, HVAC, and manufacturing. These valves control the flow of fluids and gases to ensure efficient operation of equipment and systems. However, finding the right valve for your needs can be a daunting task, especially with the vast array of options available in the market. This comprehensive guide aims to explore the world of hardware wholesale valves and provide you with all the information you need to make an informed decision. We will cover different types of valves, such as ball valves, check valves, and globe valves, and their applications. We will also discuss factors to consider when selecting valves, including pressure ratings, material selection, and installation requirements. In addition, we will showcase some of the top hardware wholesale valve suppliers and offer tips on how to find the best deals. Whether you are a seasoned professional or just starting out in the industry, this guide will help you navigate the world of hardware wholesale valves with ease. So what are you waiting for? Start exploring today!

Introduction to Hardware Wholesale Valves

Hardware wholesale valves are essential components in a vast array of industries, including plumbing, water supply, and energy. These mechanical devices regulate and control the flow of fluids, ensuring efficient and safe operation. In this article, we will delve into the world of hardware wholesale valves, exploring their types, functions, selection, and maintenance practices.

Types of Hardware Wholesale Valves

Hardware wholesale valves can be broadly categorized into five main types based on their structure and operating principles:

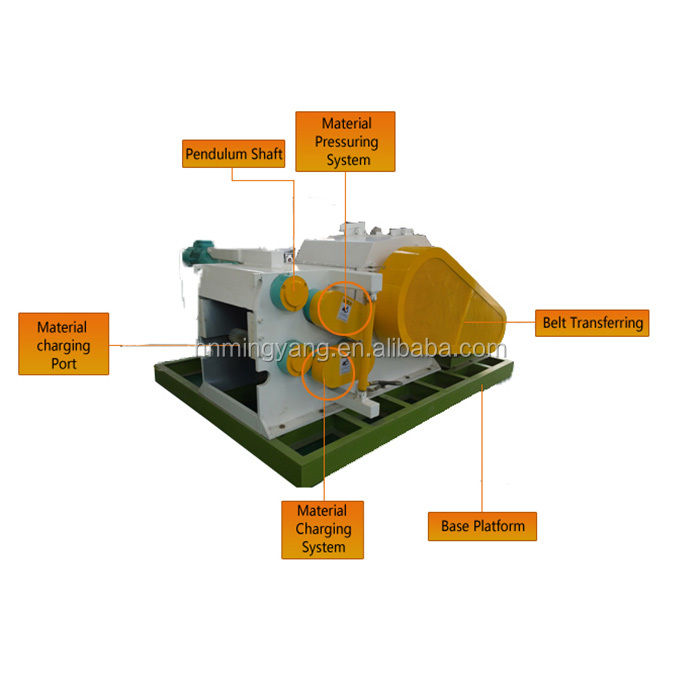

Control Valves: These valves are used to control the flow rate, pressure, and temperature of fluids in various processes. They come in different designs, such as ball valves, diaphragm valves, pneumatic valves, and solenoid valves.

Safety Valves: Safety valves are designed to protect equipment from excessive pressure or fluid level by interrupting the flow path automatically. They come in various shapes and sizes, including discriminating safety valves, pressure relief valves, and surge protection valves.

Valve Actuators: Valve actuators are responsible for opening and closing the valve to regulate fluid flow. They can be electric, pneumatic, hydraulic, or manual, depending on the application.

Non-Return Valves: Non-return valves ensure that the fluid in one direction flows only, preventing backflow and maintaining system efficiency. They are commonly used in irrigation systems, water treatment plants, and chemical processing facilities.

Trunnion Valves: Trunnion valves are attached to the stem of a valve using a trunnion pin and a spherical bearing. They offer smooth operation and high reliability but are more expensive than other types of valves.

Functions of Hardware Wholesale Valves

Hardware wholesale valves play a crucial role in maintaining optimal system performance and safety. Their primary functions include:

Flow Control: Valves regulate the flow rate and direction of fluids, ensuring that they meet specific requirements for process efficiency and safety.

Pressure Regulation: Valves help manage pressure in piping systems by regulating the flow rate and preventing overpressure. This is particularly important in hazardous applications where even small variations in pressure can have severe consequences.

Temperature Control: Some valve types, such as thermostatic valves and bimetallic strips, can adjust the temperature inside pipes by changing the fluid flow. This helps maintain consistent temperatures throughout the system and ensures product quality.

Protection against Overloading and Backflow: Valves protect equipment from excessive pressure or fluid levels by shutting off the flow path in case of emergencies. They also prevent backflow by keeping liquids from flowing in the opposite direction.

Optimizing System Efficiency: By selecting the right type and size of valve for each application, hardware wholesalers can optimize system efficiency, reduce costs, and minimize maintenance requirements.

Selecting the Right Hardware Wholesale Valves

The process of selecting hardware wholesale valves involves several factors to consider, including:

Functional Requirements: Define the specific functions that the valve must perform, such as flow control, pressure regulation, or temperature control.

Operating Conditions: Consider the operating conditions of the system, including temperature, pressure, and fluid composition. This will help determine the appropriate type of valve for the application.

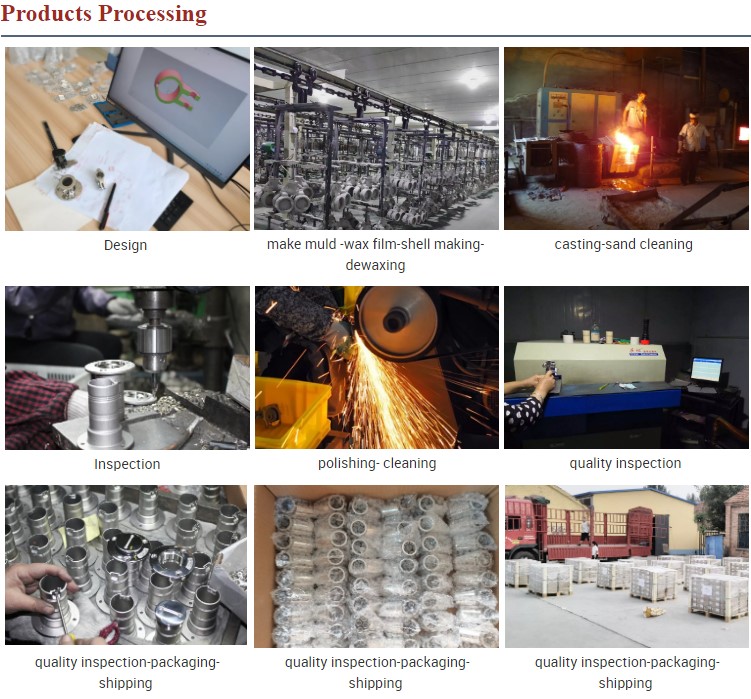

Installation and Maintenance Needs: Take into account the installation space, access points, and maintenance requirements when choosing a valve. Some valve types are easier to install and maintain than others.

Material Selection: Select materials that are compatible with the fluid being handled and that offer adequate corrosion resistance and durability. For instance, stainless steel is commonly used in harsh environments where corrosion is a concern.

Cost-Effectiveness: Compare the cost of different valve types to find the most cost-effective option that meets your budget and requirements. Consider long-term savings on maintenance

Articles related to the knowledge points of this article:

Fujian Hardware Bracket Wholesale

Title: Exploring the Wonders of the Guilin Hardware and Electrical Equipment Wholesale Market

Wholesale Smart Lock Hardware: A Comprehensive Guide

Title: Exploring the World of Chengdu Hardware Wholesale: A Guide to Sourcing Quality Products