Understanding Hardware Batch Production: The Process and Benefits

Hardware batch production is a process where multiple identical units of a product are manufactured in a short period. It involves the assembly of parts, testing, and packaging of the final product. The benefits of hardware batch production include increased efficiency, reduced costs, and improved quality control. By producing multiple units at once, manufacturers can reduce the time and resources required for each individual unit, resulting in faster delivery times and lower prices. Additionally, batch production allows manufacturers to identify and correct issues early on in the production process, reducing the risk of costly errors down the line. Overall, hardware batch production is an effective way for manufacturers to produce large quantities of high-quality products at a competitive cost.

Hardware batch production is a process of producing a large quantity of customized hardware products. This method is commonly used in the manufacturing industry to produce high-quality products at a faster rate than traditional, one-off production methods. In this article, we will explore what hardware batch production is, its advantages, and the steps involved in the production process.

1、What is Hardware Batch Production?

Hardware batch production refers to the process of producing a large number of customized hardware products in a single run. This method is typically used by manufacturers who need to produce a high volume of identical or similar products quickly and efficiently. The benefits of hardware batch production are numerous, including reduced production costs, increased productivity, and improved product consistency.

2、Advantages of Hardware Batch Production

There are several advantages to using hardware batch production in your manufacturing process. Some of the most significant benefits include:

a) Reduced Production Costs: By producing multiple units of a product simultaneously, manufacturers can reduce their overall production costs. This is because they only need to buy the raw materials once, rather than multiple times for individual units. Additionally, the use of advanced manufacturing technologies such as 3D printing and automation can further reduce production costs.

b) Increased Productivity: Hardware batch production allows manufacturers to produce multiple units of a product in a shorter amount of time than traditional, one-off production methods. This increase in productivity can lead to faster turnaround times and higher profits for the manufacturer.

c) Improved Product Consistency: By producing multiple units of a product using the same production process and quality control measures, manufacturers can ensure that each unit meets the same standards of excellence. This improved consistency can help to build brand reputation and customer trust.

d) Scalability: Hardware batch production is highly scalable, meaning that it can be adapted to meet changing demand levels. This makes it an ideal solution for manufacturers who need to produce a variety of products over time, or who want to expand their business without investing in additional equipment or resources.

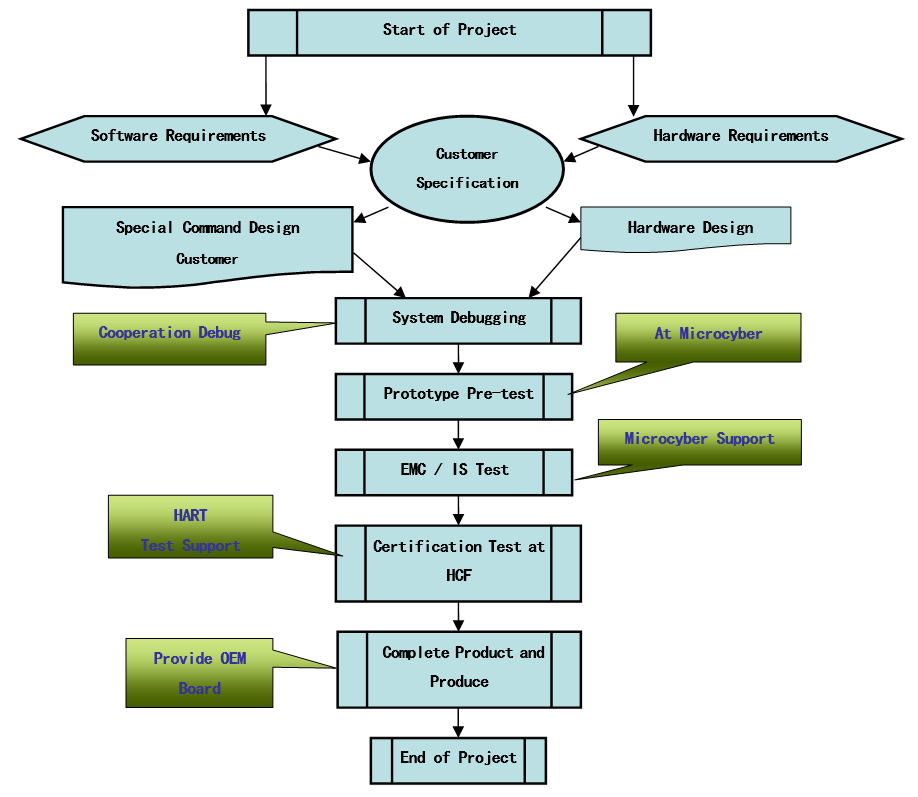

3、Steps in the Hardware Batch Production Process

The hardware batch production process involves several key steps, including design, prototyping, tooling development, production, and quality control. Here's a closer look at each of these steps:

a) Design: The first step in hardware batch production is to design the product according to the specific requirements of the customer. This may involve creating detailed drawings and specifications, selecting materials and components, and testing the design to ensure that it meets the necessary performance standards.

b)Prototyping: Once the design has been finalized, it is time to create a prototype of the product. This prototype will be used to test the manufacturing process and ensure that the final product meets the desired specifications. Prototyping can be done using a variety of techniques, including 3D printing and CNC machining.

c) Tooling Development: Tooling refers to the specialized tools and equipment required to manufacture a product. In hardware batch production, tooling must be developed separately for each product variant being produced. This includes creating molds, stamping dies, and other precision tools required for the assembly process.

d)Production: With the design, prototype, and tooling in place, it is time to begin mass-producing the final product using hardware batch production techniques. This may involve using automated machinery, such as robots or injection molding machines, to perform repetitive tasks such as assembly or packaging.

e) Quality Control: Once the initial batch of products has been produced, it is important to conduct thorough quality control measures to ensure that each unit meets the required standards of performance and appearance. This may involve subjecting the products to various tests and inspections, such as strength testing or visual inspections.

4、Conclusion

Hardware batch production is an effective way for manufacturers to produce large volumes of customized hardware products quickly and efficiently. By reducing production costs, increasing productivity, and improving product consistency, this method can help manufacturers stay competitive in today's fast-paced marketplace. Whether you're looking to scale your business or simply produce high-quality custom hardware products, hardware batch production is worth considering as part of your manufacturing strategy.

Articles related to the knowledge points of this article:

Custom Metal Fabrication Services for Your Unique Needs

The Customization of Small Hardware Products at a Local Factory