Customized Hardware Valves: The Ultimate Guide

This ultimate guide to customized hardware valves provides a comprehensive understanding of the various types of valves available and their specific applications. From simple to complex, this guide covers it all.Chapter One introduces the reader to the world of hardware valves, explaining the role they play in our daily lives. From water control to air conditioning, valves are crucial to the functioning of many systems.Chapter Two delves into the different types of hardware valves. From ball valves to butterfly valves, this chapter explains the unique characteristics and applications of each type. The reader learns about the pros and cons of each valve, helping to make an informed decision when selecting a valve for a particular application.Chapter Three focuses on customized hardware valves. With the help of a professional manufacturer, the reader can create a valve that is tailored to their specific needs. This chapter discusses the design process, materials selection, and quality assurance measures that go into creating a customized valve.Chapter Four covers the installation and maintenance of hardware valves. The reader learns how to properly install a valve and keep it functioning properly over time. Tips and tricks are provided to help extend the life of a valve and prevent common problems.This guide is essential for anyone who works with hardware valves or is interested in learning more about them. From beginners to experts, this guide has something for everyone.

Hardware valves are crucial components in various applications, offering control over the flow of liquids or gases. From simple to complex systems, these valves play a vital role in maintaining the efficiency and safety of operations. In this guide, we explore the world of customized hardware valves, discussing the importance, benefits, and challenges associated with them.

Why Customized Hardware Valves are Needed

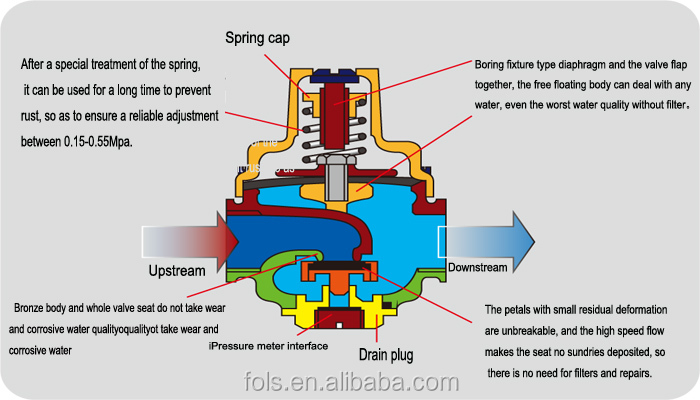

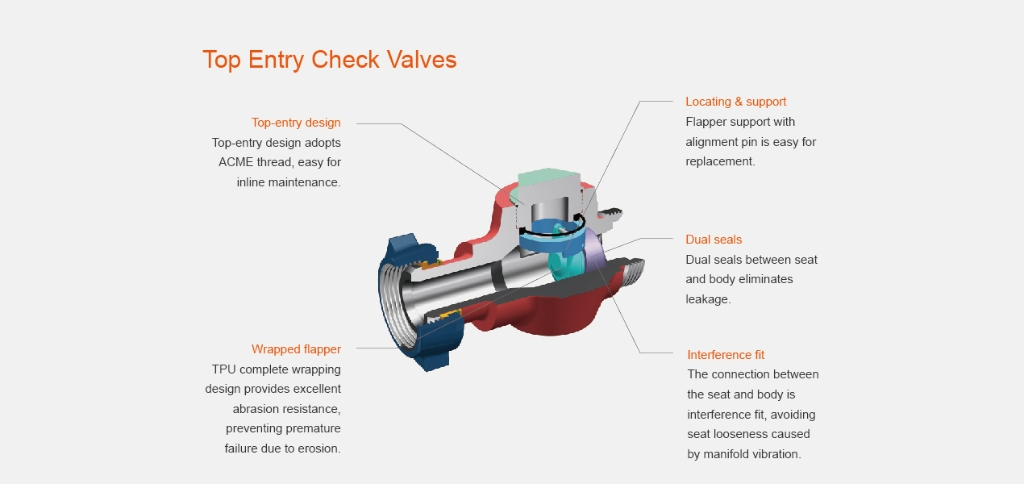

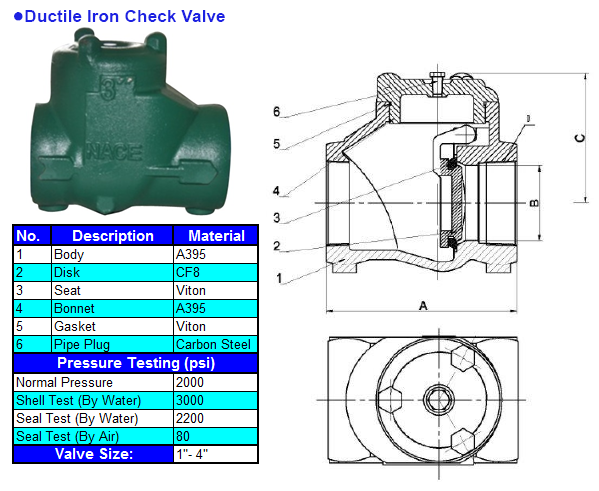

The need for customized hardware valves arises due to the diverse range of applications and industries that utilize them. From simple plumbing systems to complex machinery, each application has specific requirements that need to be met. Standard valves may not provide the precision or performance needed for certain applications, leading to inefficient operations or even safety hazards. By contrast, customized hardware valves can be designed and manufactured to meet the specific needs of each application, ensuring optimal performance and safety.

Benefits of Customized Hardware Valves

1、Improved Efficiency: Customized hardware valves can be designed to optimize the flow of liquids or gases, reducing resistance and increasing efficiency. This can lead to reduced energy consumption and increased productivity.

2、Enhanced Safety: By ensuring that valves are designed for their specific application, customized hardware valves can help to reduce the risk of accidents or failures. This can lead to a safer and more reliable operation.

3、Long-term Cost Savings: While the initial cost of customized hardware valves may be higher than standard valves, the long-term cost savings can be significant. By reducing energy consumption and maintenance costs, customized valves can provide a payback over time.

4、Unique Solutions for Unique Applications: Each application has its own set of challenges and requirements. Customized hardware valves can be designed to address these unique challenges, providing a tailored solution that meets the specific needs of each application.

Challenges of Customized Hardware Valves

1、High Cost: The cost of designing and manufacturing customized hardware valves can be high, requiring significant investment from businesses. This can make it difficult for some companies to justify the cost of customization.

2、Long Lead Times: The process of designing and manufacturing customized hardware valves can take longer than standard valves. This can lead to delays in projects or operations that rely on these components.

3、Technical Complexity: Customized hardware valves require a high level of technical expertise to design and manufacture effectively. This can pose a challenge for companies that lack the necessary in-house expertise or resources to support customization efforts.

In conclusion, customized hardware valves offer significant benefits in terms of efficiency, safety, and cost savings compared to standard valves in specific applications. However, the high cost and technical complexity associated with customization efforts can pose challenges for businesses. By carefully evaluating these challenges and balancing them against the potential benefits, companies can make informed decisions about whether to pursue customized hardware valve solutions for their applications.

Articles related to the knowledge points of this article:

Whole House Customization: Giant Forest Hardware

Europeanus: A Comprehensive Guide to Custom Hardware for Your Home

Unique Hardware for Customized Furniture

Title: Customization of Metal Hardware: A Comprehensive Guide

Title: Custom furniture hardware manufacturing in Xiamen - A Comprehensive Guide