Custom Metal Fabrication Steps

Custom metal fabrication is a process that involves the creation of metal components and structures according to specific designs and requirements. The process begins with the selection of the appropriate metal material, which is then cut, shaped, and formed into the desired shape using various techniques such as machining, welding, or bending. Custom metal fabrication steps may also include the application of coatings or finishes to protect the metal from corrosion or enhance its appearance. Once the fabrication process is completed, the finished product is inspected for quality assurance and then shipped to the customer. This process allows for the creation of unique and complex metal components that meet the specific needs of the customer.

Metal fabrication is a crucial process in various industries, offering numerous benefits such as durability, versatility, and longevity. When it comes to custom metal fabrication, it involves several crucial steps that ensure the final product meets the specific requirements and standards. This article outlines the essential steps involved in custom metal fabrication to help you understand the process better.

1、Design Phase

The first step in custom metal fabrication is the design phase. This phase involves understanding the specific requirements of the customer and creating a detailed design that meets those needs. Designers use CAD (Computer-Aided Design) software to create 3D models that represent the final product. This ensures that the product is precisely designed and can be easily modified to meet any changes in the customer’s requirements.

2、Material Selection

Once the design is completed, the next step is to select the right metal material for the job. Different industries and applications require different metal materials, so it’s essential to choose the one that offers the best combination of strength, durability, and cost-effectiveness. Common metal materials used in custom metal fabrication include steel, aluminum, copper, and titanium.

3、Cutting and Forming

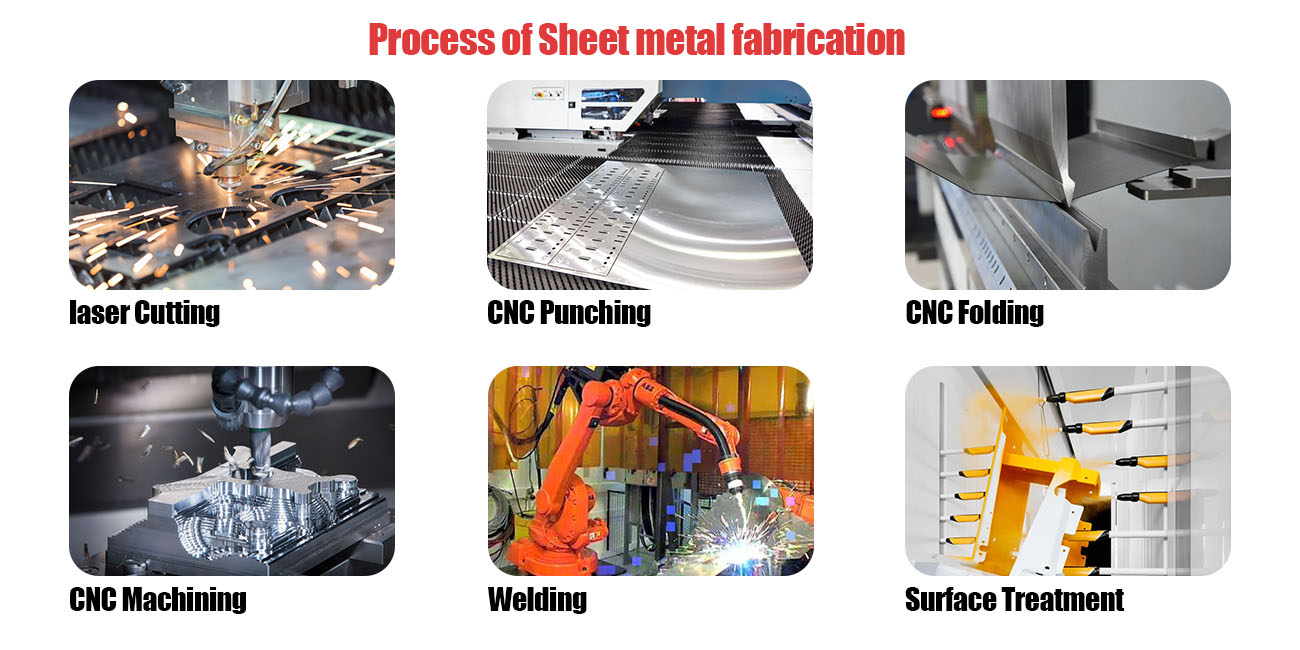

The next step is to cut and form the metal material into the desired shape. This process can involve using various cutting tools and techniques, such as lasers, plasma cutters, or waterjets. The choice of cutting tool depends on the type of metal material being used and the precision required for the job. Once the metal is cut into shape, it can then be formed using bending, rolling, or welding techniques to create the final product.

4、Finishing and Assembly

Once the metal has been cut and formed, it needs to be finished and assembled into its final form. This step involves removing any burrs or rough edges from the metal surface using sanding or grinding techniques. It also involves applying any necessary coatings or treatments to protect the metal from corrosion or wear and tear. Once the finishing touches have been applied, the individual pieces can then be assembled together to create the final product.

5、Quality Assurance and Testing

The final step in custom metal fabrication is quality assurance and testing. This ensures that the final product meets all specified standards and requirements. Quality assurance techniques involve inspecting the product for defects or impurities using x-ray, ultrasound, or magnetic particle testing methods. Testing may also involve loading or stressing the product to ensure it can withstand its intended use without failing prematurely.

In conclusion, custom metal fabrication involves several crucial steps that ensure the final product is of high quality and meets specific requirements. From design to material selection, cutting and forming, finishing and assembly, and finally quality assurance and testing, each step is essential in creating a durable and reliable metal product that will perform well in its intended application.

Articles related to the knowledge points of this article:

Title: How to Choose the Right Door and Window Hardware for Custom Installations

What are the Five Golds for Whole House Customization?

Yuhuan Custom Hardware for Doors and Windows