Leveraging Integration in Hardware Wholesale: The Future of Supply Chain Management

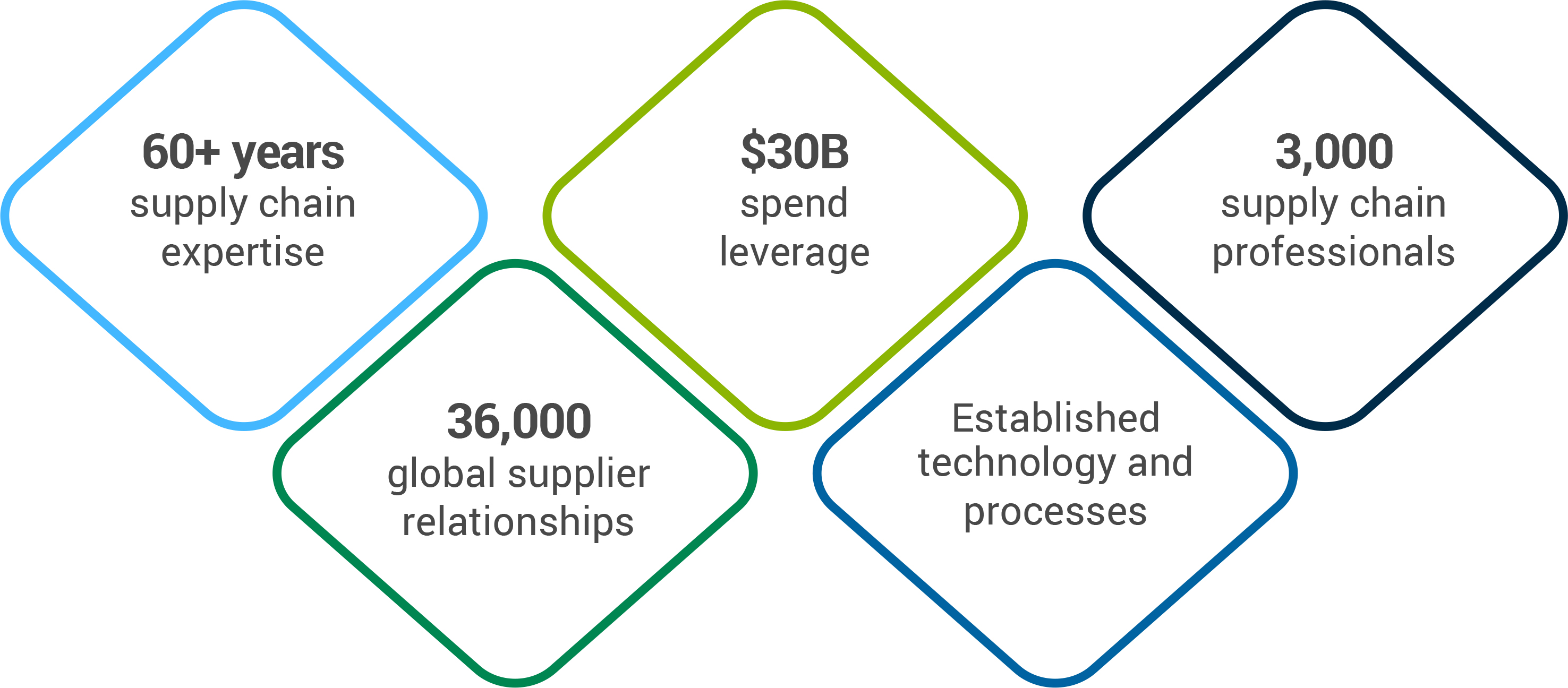

As the global economy continues to grow and technology advances, businesses must find new ways to optimize their supply chain management. One solution that has gained popularity in recent years is leveraging integration in hardware wholesale. By integrating various software tools and systems into a single platform, businesses can streamline their operations and reduce costs. This approach allows for real-time tracking of inventory, improved communication between suppliers and customers, and faster order fulfillment times. As a result, companies can improve their bottom line while increasing customer satisfaction. The future of supply chain management lies in the ability to integrate all aspects of the business, including production, transportation, and logistics. By embracing this approach, businesses can stay ahead of the competition and meet the ever-increasing demand for efficient and effective supply chain management.

In the world of business, the success of any company is often determined by its ability to manage supply chains effectively. This is especially true for industries such as hardware wholesale, where a multitude of factors can impact product availability, prices, and quality. One way to address these challenges is through strategic integration. By integrating different aspects of the supply chain, companies can streamline operations, reduce costs, and improve customer satisfaction. This is particularly important in the field of hardware wholesale, where large quantities of products need to be moved efficiently and at low cost.

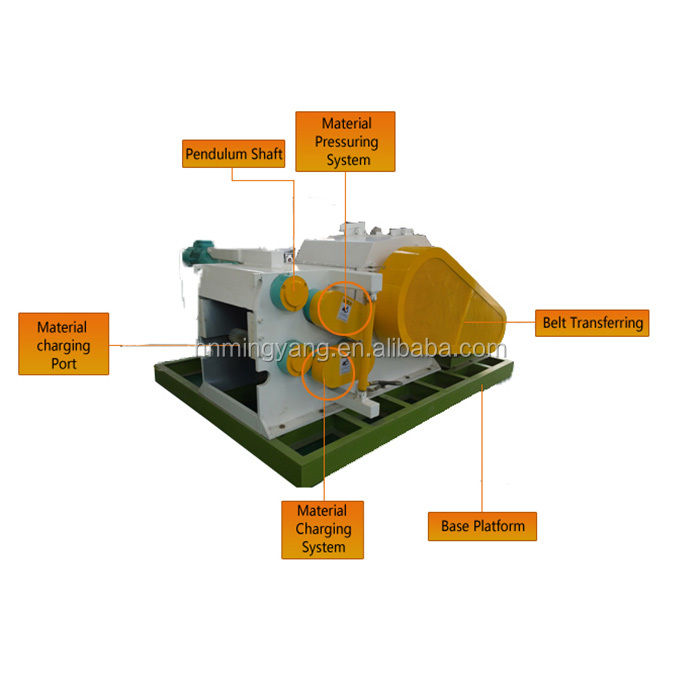

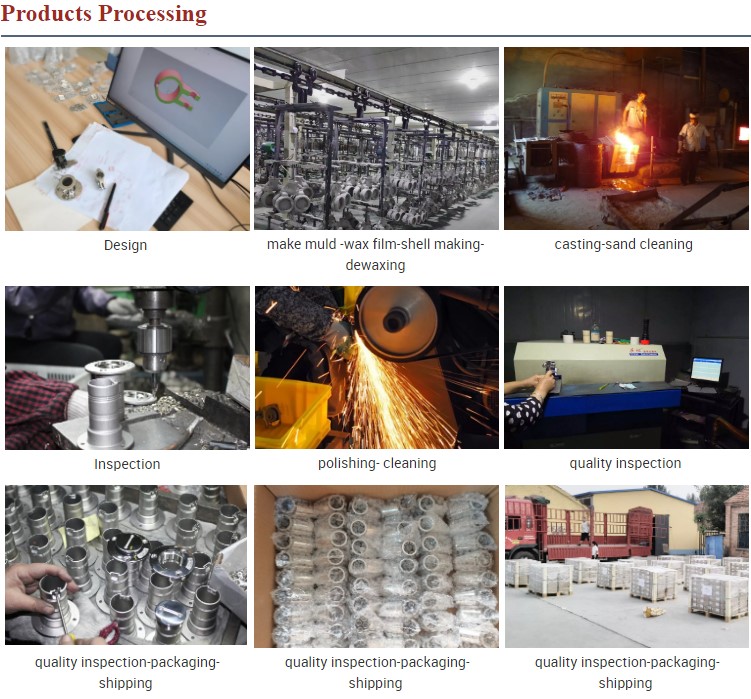

Hardware wholesale involves the buying and selling of large quantities of hardware products, such as tools, machinery, and equipment. This type of wholesale requires careful management of inventory, logistics, and relationships with suppliers and customers. Traditionally, hardware wholesalers have relied on manual processes and intermediaries to manage these activities. However, with the advent of technology, there are now many opportunities to integrate different aspects of the supply chain, leading to significant improvements in efficiency and effectiveness.

One area where integration can be particularly beneficial is in automating processes. For example, software systems can be used to track inventory levels in real-time, reducing the risk of overstocking or stockouts. Similarly, automated order processing systems can speed up the delivery of orders from suppliers to customers, reducing wait times and improving customer satisfaction. Furthermore, data analytics tools can provide valuable insights into customer behavior and market trends, allowing hardware wholesalers to make more informed decisions about inventory management, pricing策略, and marketing efforts.

Integration also has the potential to improve communication and collaboration among different parts of the supply chain. For example, electronic data interchange (EDI) can be used to exchange transactional data between businesses, reducing the need for manual data entry and increasing the speed and accuracy of transactions. Similarly, cloud-based systems can facilitate remote work and collaboration among employees and suppliers, breaking down geographical barriers and allowing for more efficient coordination of activities.

Another way in which hardware wholesalers can benefit from integration is through the use of artificial intelligence (AI) and machine learning (ML). These technologies can be used to optimize various aspects of the supply chain, from predictive maintenance of equipment to demand forecasting for raw materials. For example, ML algorithms can analyze historical data to identify patterns and trends that indicate future demand for certain products. This information can then be used to adjust inventory levels and production schedules accordingly, reducing waste and improving profitability. Similarly, AI-powered chatbots can provide customers with personalized service and support, answering questions about products and services in real-time.

Of course, implementing integration in hardware wholesale is not without its challenges. One major obstacle is the need for high-quality data. In order for AI and ML algorithms to perform well, they require large amounts of accurate data to train on. This means that hardware wholesalers must invest in data collection and management systems that can provide reliable and relevant data across their entire supply chain. Another challenge is the need for strong organizational culture and leadership support. Integration requires a willingness to experiment with new processes and technologies, as well as a commitment to continuous improvement. Companies that are able to embrace change and prioritize innovation are likely to see the greatest benefits from integrated supply chain management.

Despite these challenges, the potential benefits of integration in hardware wholesale are too great to ignore. By automating processes, improving communication and collaboration, and leveraging AI and ML technologies, hardware wholesalers can increase efficiency, reduce costs, improve customer satisfaction, and gain a competitive advantage in an increasingly complex marketplace. As the industry continues to evolve at a rapid pace, those who are able to embrace these changes will be best positioned for success in the years ahead.

Articles related to the knowledge points of this article:

Title: Exploring the World of Hardware Wholesale: A Comprehensive Guide to Online五金批发 Websites

Wholesale Hardware Valve Plate

Shun Da Paint & Hardware Wholesale