Customization of Metal Hardware Components in Shandong Province: A Comprehensive Guide

Shandong Province is a hub for metal hardware manufacturing in China. With its rich resources and advanced technology, the province offers a comprehensive guide for customization of metal hardware components. This guide covers all aspects of customization, from design to production, including material selection, shape and size customization, surface treatment, and assembly. It also provides information on quality control measures, such as testing and inspection, to ensure product consistency and meet customer requirements. The guide emphasizes the importance of communication and collaboration between manufacturers, designers, and customers to achieve the best possible results. By following this comprehensive guide, manufacturers can enhance their competitiveness and expand their market share in the thriving metal hardware industry of Shandong Province.

Introduction

Shandong, located in the eastern part of China, is a leading manufacturer of hardware products. With its abundant natural resources and well-developed industrial infrastructure, Shandong has become a hub for metal hardware manufacturing. In this article, we will discuss the process of customization of metal hardware components in Shandong, focusing on various aspects such as materials, design, manufacturing, quality control, and delivery.

Material Selection for Metal Hardware Components

The choice of material is critical to the success of any hardware component. Shandong manufacturers use a wide range of metals to manufacture hardware parts, including steel, aluminum, zinc, stainless steel, and plastics. The selection of material depends on the application, environment, and cost factors. For example, steel is commonly used for structural components due to its high strength and durability; aluminum is preferred for lightweight and corrosion-resistant components; and stainless steel is suitable for kitchenware and medical equipment where hygiene is essential.

Design and Engineering for Metal Hardware Components

Effective design and engineering are crucial to ensure the functionality, safety, and aesthetics of metal hardware components. Shandong manufacturers employ advanced software tools like AutoCAD, SolidWorks, and CAE (Computer-Aided Engineering) to create detailed 3D models and simulate the performance of the components. They also work closely with customers to understand their requirements and incorporate them into the design. Moreover, they follow international standards and regulations like ISO 9001:2015, which ensures compliance with quality management principles.

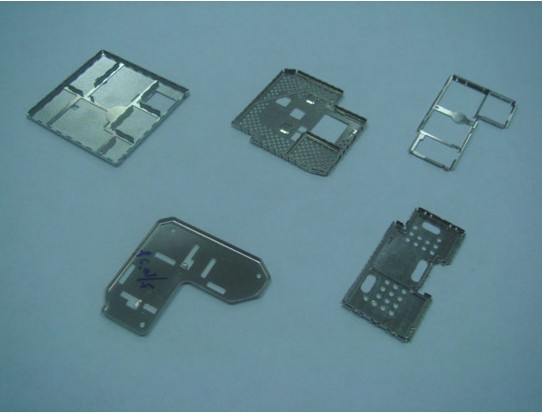

Manufacturing Process for Custom Metal Hardware Components

The manufacturing process involves various steps such as cutting, bending, welding, stamping, drilling, grinding, and assembly. Shandong manufacturers utilize advanced machines and technologies like CNC (Computer Numerical Control) machines, robots, and automatic lines to streamline the production process. They also adhere to strict quality control procedures like visual inspection, dimensional accuracy testing, and surface finish evaluation to ensure consistent quality across batches. Furthermore, they adopt lean manufacturing practices like Just-In-Time (JIT) and Total Quality Management (TQM) to minimize waste and improve efficiency.

Quality Control for Customized Metal Hardware Components

Quality control is a continuous process that involves inspecting raw materials, processing stages, finished goods, and packaging. Shandong manufacturers employ various methods like visual inspection, chemical analysis, mechanical testing, and non-destructive testing (NDT) to verify the compliance with specifications and standards. They also conduct regular training sessions for employees to update their knowledge and skills. Additionally, they have established quality management systems like ISO 9001:2015 to ensure traceability and accountability throughout the supply chain.

Delivery and Shipping of Custom Metal Hardware Components

After the final inspection and approval, customized metal hardware components are packed securely and shipped to the destination via air freight or sea freight. Shandong manufacturers work closely with logistics providers to ensure timely delivery within the specified timeframe. They also provide documentation like commercial invoices, packing lists, shipping certificates, and inspection reports to facilitate customs clearance and comply with local regulations. Furthermore, they offer after-sales support like warranty repairs, maintenance services, and spare parts supply to enhance customer satisfaction.

Conclusion

Customizing metal hardware components in Shandong offers numerous benefits such as flexibility, customization options, competitive pricing, and high-quality products. By understanding the key processes involved in customization, customers can effectively collaborate with Shandong manufacturers to achieve their project goals. Whether you need standard or customized components for your organization or personal projects, Shandong's expertise in metal hardware manufacturing can help you meet your requirements efficiently and cost-effectively.

Articles related to the knowledge points of this article:

Customizing Jiangsu Hardware Oven for Baking

Custom Door Hinge Manufacturing Factory: The Art of Crafting Perfect Hardware

Title: Customizing Hardware Intra-Pallet Trays in Hunan Province: A Comprehensive Guide

Title: Custom Metal Connector Terminal Manufacturing: A Comprehensive Guide

Custom Hardware Machinery: A Comprehensive Guide

Bag Hardware Customization: A Detailed Look into the Process