Customization of Liaoning Precision Metal Stampings: A Comprehensive Guide

Liaoning Precision Metal Stampings is a leading manufacturer of precision metal stampings in China. The customization process involves several steps that are crucial for producing high-quality products. The first step is to determine the material and specifications of the product, including the dimensions, shape, and weight. The next step involves designing the product using computer-aided design (CAD) software, which ensures accuracy and efficiency. Once the design is finalized, the production process begins by cutting and shaping the raw materials into precise shapes. The final step is finishing, which involves polishing, painting, and packaging the product. It is important to note that Liaoning Precision Metal Stampings offers a wide range of customization options to meet the diverse needs of its clients. With its state-of-the-art equipment and experienced team, Liaoning Precision Metal Stampings ensures consistent quality and timely delivery of products. Whether you need customized metal stampings for automotive, aerospace, or consumer products, Liaoning Precision Metal Stampings has the expertise to deliver high-quality products that meet your specific requirements.

Introduction

In the world of manufacturing, metal stampings have become an essential component in the production process. They are used in various industries to create high-quality products with intricate designs and precise dimensions. Among the leading manufacturers of metal stampings in China, Liaoning Province stands out for its exceptional quality and customized services. This article aims to provide a comprehensive guide to Liaoning precision metal stampings, highlighting their benefits, applications, and the process of customization.

Liaoning Province: A Hub of Metal Stampings Manufacturing

Located in northeastern China, Liaoning Province has emerged as a significant player in the global metal stampings industry. The region's strategic location, skilled workforce, and advanced technology have contributed immensely to its growth. Today, Liaoning is home to numerous metal stamping plants that produce high-quality components for various industries, including automotive, electronics, aerospace, and more.

Benefits of Liaoning Precision Metal Stampings

Liaoning precision metal stampings offer several benefits to clients, including:

1、High-Quality Standards: Liaoning's metal stamping plants adhere to strict quality control standards, ensuring that each product meets client specifications. The state-of-the-art equipment and advanced technologies employed by these plants further enhance the quality of the final products.

2、Customizable Designs: Liaoning's experienced engineers can design custom-made metal stamping components to meet specific client requirements. This flexibility enables clients to create unique products that stand out in the market.

3、Fast Turnaround Times: Liaoning's efficient production processes ensure that projects are completed quickly without compromising on quality. This makes it ideal for clients who require urgent delivery of custom components.

4、Cost-Effective: By producing high-quality components in large quantities, Liaoning offers clients cost-effective solutions that save them money in the long run.

Applications of Liaoning Precision Metal Stampings

Liaoning precision metal stampings have a wide range of applications across various industries, including:

1、Automotive Industry: Liaoning's metal stamping plants produce components for major automotive manufacturers, such as engines, transmissions, and body parts. These components are essential for the proper functioning of modern vehicles and contribute significantly to their safety and performance.

2、Electronics Industry: Liaoning's metal stamping plants produce components for electronic devices like smartphones, laptops, and televisions. These components include circuit boards, casings, and other essential parts that ensure the smooth operation of electronic equipment.

3、Aerospace Industry: Liaoning produces metal stamping components for aerospace systems like airplane wings, fuel tanks, and engine components. These components play a crucial role in maintaining the safety and efficiency of aviation operations.

4、Medical Industry: Liaoning manufactures metal stamping components for medical devices like surgical instruments, implants, and prosthetic limbs. These components are essential for improving patient care and recovery outcomes.

5、Other Industries: Liaoning's metal stamping plants also produce components for other industries like construction, agriculture, and defense. Their versatile production capabilities make them suitable for a wide range of applications.

The Process of Liaoning Precision Metal Stamping Customization

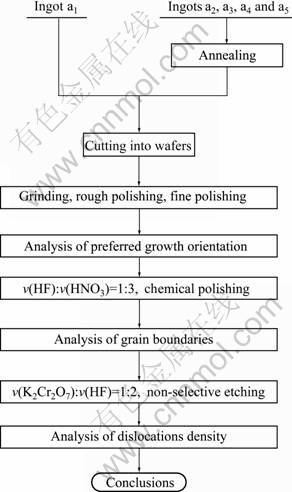

The customization process involves several steps:

1、Initial Design: Clients provide detailed drawings or specifications outlining their requirements for the custom metal stamping parts. The design must consider factors like material type, shape, size, and tolerance levels.

2、Engineering Analysis: Liaoning's experienced engineers analyze the design to determine feasibility and suggest modifications if necessary. They also calculate the required material quantity and estimate production costs based on the complexity of the part.

3、Toolmaking: Based on the initial design and engineering analysis, Liaoning's toolmakers create precision tools required for shaping the metals into the desired form. These tools may be made from various materials like steel, alloys, or ceramics depending on the material properties and part complexity.

4、Production: Once the tools are ready, Liaoning's production teams begin producing the custom metal stamping parts using state-of-the-art technologies like laser cutting, punching, and bending machines. The production process is closely monitored to ensure consistency in quality and meet client requirements.

5、Quality Control: After production is complete, Liaoning's quality control team inspects each part to ensure it meets client specifications and industry standards. Any defects or issues are addressed immediately before delivery.

6、Delivery: Once satisfied with the quality of the custom metal stamping parts, Liaoning delivers them to clients within agreed timelines. The timely delivery ensures that projects remain on schedule and clients can meet their deadlines without any delays or disruptions

Articles related to the knowledge points of this article:

Custom衣柜的五金Hardware for Custom Wardrobes

Title: The Art and Science of Customizing Small Metal Components

Title: Customized Hardware and Sanitary Ware in Nanchang: A Comprehensive Guide

Title: Customized Weifang Hardware Painting Equipment: A Comprehensive Guide