Customizing Hardware and Plastic for Unique Applications

Unique applications often require customized hardware and plastic to meet specific needs and requirements. By providing tailored solutions, these components can significantly enhance the performance, usability, and overall value of the application. Customizing hardware and plastic allows for the creation of bespoke designs that perfectly suit the intended purpose, maximizing efficiency and minimizing errors. This approach ensures that each component is tailored to its specific application, providing a bespoke and cost-effective solution to meet individual needs.

In today's world, the demand for customized hardware and plastic products has skyrocketed. From small components to large-scale applications, the need for tailor-made solutions has become integral to various industries. In this article, we explore the world of五金塑胶定制, how it works, and how it can revolutionize the way we approach industrial manufacturing.

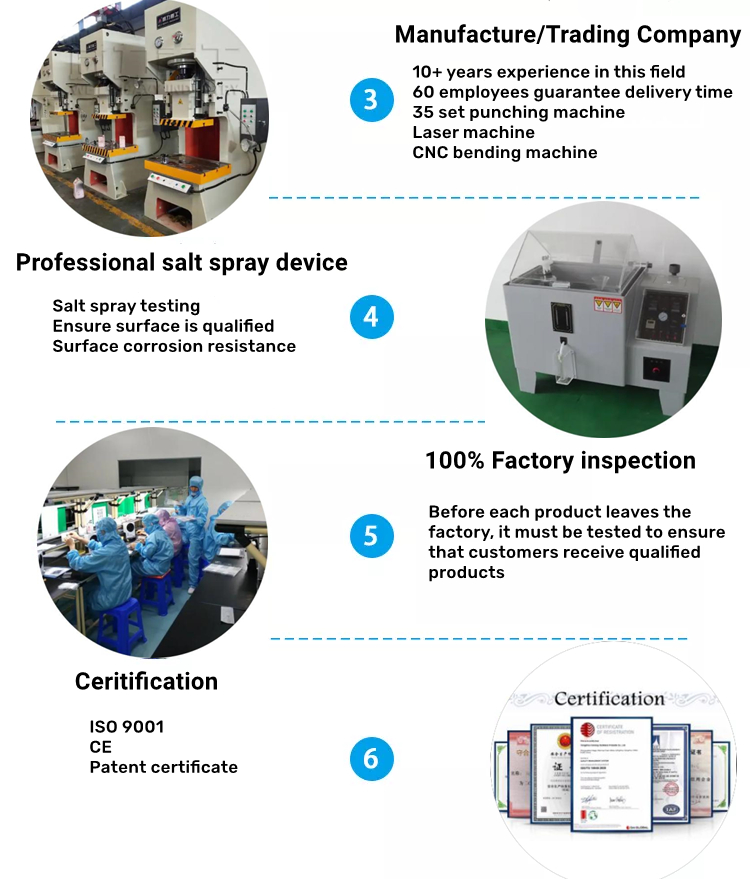

Firstly, let's talk about hardware customization. Here, the focus is primarily on metal components and their role in various machines and devices. The process of定制hardware involves understanding the specific requirements of a device or machine, such as its size, shape, and performance specifications. From there, a design is created using CAD (Computer-Aided Design) software, which ensures precision and accuracy in the final product. The next step is to use CNC (Computer Numerical Control) machines to cut, drill, or mill the raw material into the desired shape. This process ensures that each component is tailor-made to its specific application, maximizing performance and efficiency.

On the other hand, plastic customization involves a similar process but with a different material. Here, the focus is on polymers and their unique properties that make them suitable for certain applications. The process of定制plastic begins with understanding the specific requirements of an application, such as its durability, temperature resistance, and chemical compatibility. From there, a design is created using CAD software and then 3D printed or molded to create the final product. This process ensures that each plastic component is tailored to its specific application, maximizing performance and efficiency.

Now let's talk about how五金塑胶定制can revolutionize the way we approach industrial manufacturing. By having tailor-made solutions for each application, manufacturers can ensure that their products are optimized for performance and efficiency. This means that each component is designed specifically to fit its intended purpose, reducing waste, increasing productivity, and ultimately reducing costs. Additionally, having customized products can give manufacturers a competitive edge by allowing them to offer unique solutions that meet the specific needs of their customers. This ensures that each product is tailored to its intended market, maximizing customer satisfaction and brand loyalty.

In conclusion,五金塑胶定制is revolutionizing the way we approach industrial manufacturing by allowing for tailor-made solutions that maximize performance and efficiency. By understanding the specific requirements of each application and designing components to fit those requirements, manufacturers can ensure that their products are optimized for success in their respective markets.

Articles related to the knowledge points of this article:

Custom Folding Dining Table Hardware: A Guide to Selection and Installation

Custom Cabinet Hardware: DIY or Not?

Customizing Hardware and Sheet Metal for Your Needs

Title: How to Choose the Right Door Hardware for Custom Cabinets?

Title: Custom Metal Connector Terminal Manufacturing: A Comprehensive Guide