Crafting Custom Metal Corner Guards: A Comprehensive Guide to五金护角定制

Crafting Custom Metal Corner Guards: A Comprehensive Guide to Metal Corner GuardMetal corner guards, also referred to as metal corner protection, are essential components in preventing damage to walls and corners caused by heavy objects or equipment. However, the standard sizes often do not fit all areas, leading to the need for custom-made metal corner guards. This comprehensive guide aims to provide readers with a step-by-step process of creating customized metal corner guards that meet their specific requirements.The first step is to determine the measurements and design of the guard. This includes determining the size and shape of the guard, as well as any necessary features such as drainage holes or anti-slip surfaces. Once these details have been established, the next step is to select the appropriate material for the guard. Common materials used for metal corner guards include stainless steel, aluminum, and galvanized steel.After selecting the material, the guard can be shaped using various techniques such as bending, cutting, and welding. It is essential to ensure that the guard is sturdy and durable while also being lightweight enough to be easily installed. Once the guard has been created, it can be tested for its effectiveness by placing heavy objects or equipment at different angles around the corner.In conclusion, custom metal corner guards are an effective way to prevent damage to walls and corners caused by heavy objects or equipment. By following this comprehensive guide, individuals can create customized guards that meet their specific requirements and ensure safety in their workspaces.

Introduction

Metal corner guards, also known as metal corner caps or metal corner protectors, are essential components used in a variety of industries, including construction, automotive, and electronics. These guards serve several purposes, including protecting against damage, providing a clean finish, and improving the overall appearance of surfaces. In this article, we will discuss the process of customizing metal corner guards and provide tips on selecting the right materials and design for your specific needs.

Material Options

When it comes to custom metal corner guards, there are several materials from which to choose. The most common choices include:

1、Stainless Steel: Stainless steel corner guards are durable, corrosion-resistant, and available in a wide range of grades and finishes. They are ideal for use in harsh environments such as food processing plants, chemical facilities, and water treatment systems.

2、Aluminium: Aluminium corner guards are lightweight, strong, and resistant to rust. They are commonly used in aerospace, marine, and architectural applications due to their high strength-to-weight ratio.

3、Brass: Brass corner guards offer excellent resistance to corrosion and possess a warm golden hue that is often preferred in decorative applications. They are commonly used in plumbing and electrical systems where a shiny finish is desired.

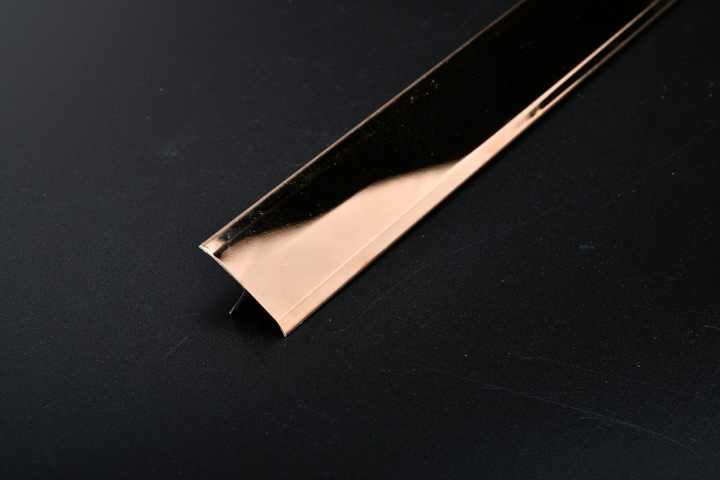

4、Copper: Copper corner guards are highly conductive and have excellent thermal properties, making them ideal for use in heating and cooling systems. They are also resistant to corrosion and can be finished to match the surrounding material.

Design Considerations

In addition to selecting the right material, it is essential to consider the design of your custom metal corner guard. Here are some factors to keep in mind when designing your guard:

1、Shape: The shape of your guard will depend on the specific application and the type of material you select. Some common shapes include round, square, and triangular.

2、Height: The height of your guard will determine how much protection it offers against damage. taller guards provide more coverage but may not be suitable for areas with limited space.

3、Edge Profile: The edge profile of your guard can have a significant impact on its appearance and functionality. options include sharp corners, rounded edges, and beveled edges.

4、Holes and Cutouts: If you need your guard to fit into a specific opening or require access for maintenance, you will need to consider adding holes or cutouts to the guard's design. Be sure to specify the size and location of any necessary openings when ordering your guard.

Ordering Process

Once you have selected the appropriate material and design for your custom metal corner guard, the next step is to place an order. Here are the general steps you should follow:

1、Determine Your Needs: Before placing an order, carefully consider your specific requirements for the guard, such as size, material, design, and delivery date. This will help you select the right product from our catalog or request a custom quote from our customer service team.

2、Select Your Product: From our catalog or by requesting a custom quote, select the appropriate metal corner guard that meets your needs. Be sure to specify your requirements for material, design, and size if necessary.

3、Place Your Order: Once you have selected your product, submit your order through our website or customer service team. Be sure to provide all necessary information about your project, including measurements, material specifications, and any special instructions for customization.

4、Monitor Your Order: Our production team will begin working on your order as soon as it is received. You can monitor the progress of your order through our online status tracking system or by contacting our customer service team directly.

5、Receive Your Guard: When your guard is ready for delivery, we will ship it to you via the method and carrier of your choice. Be sure to check the dimensions of your guard upon receipt to ensure everything matches your original specifications.

Articles related to the knowledge points of this article:

Custom Home Package: Five Hardware Components

Title: Chongqing Hardware Customization Manufacturers

Title: Custom Metal模具外壳 Manufacturing: A Comprehensive Guide

Title: Customizing Metal Products in Foshan: A Comprehensive Guide to Quality and Accuracy