The Art and Science of Wire Drawing in Hardware Parts Manufacturing

Wire drawing is a crucial process in the hardware parts manufacturing industry, as it not only adds aesthetic appeal to the finished product but also increases mechanical strength and wear resistance. However, mastering the art and science of wire drawing requires a deep understanding of metallurgy, physics, and engineering principles. The process involves feeding wires through the material being drawn, which causes the metal to be stretched and pulled into a thin, flat sheet. The wire used can vary in diameter, thickness, and type depending on the desired finish and properties of the final product. There are several techniques for wire drawing, including linear drawing, loop drawing, and swaging. Each technique has its unique advantages and limitations, and engineers must carefully consider factors such as material compatibility, draw length, and draw speed to achieve the desired results. In addition to the technical aspects of wire drawing, there are also practical considerations such as tool design and maintenance, operator training, and quality control measures. By mastering the art and science of wire drawing, hardware manufacturers can produce high-quality products with enhanced performance and durability.

Introduction to Wire Drawing Process in五金配件制造

Understanding the Principles of Metal Deburring

The Role of Surface Finish in Hardware Product Functionality

Wire Drawing Techniques: A Comprehensive Guide

From Mill to Machine: The Evolution of Wire Drawing in Manufacturing

Wire Drawing as a Surface Treatment Option: Benefits and Limitations

Deburring vs. Wire Drawing: Which is Right for Your Hardware Needs?

The Microscopic World of Wire Drawing: An Engineering Perspective

The Significance of Wire Drawing in Enhancing the Durability and Reliability of Metal Components

The wire drawing process: An overview of different methods and applications

Wire Drawing for Surfacefinishing: A Technological Overview

From Raw Materials to finished Products: The Wire Drawing Journey of五金配件

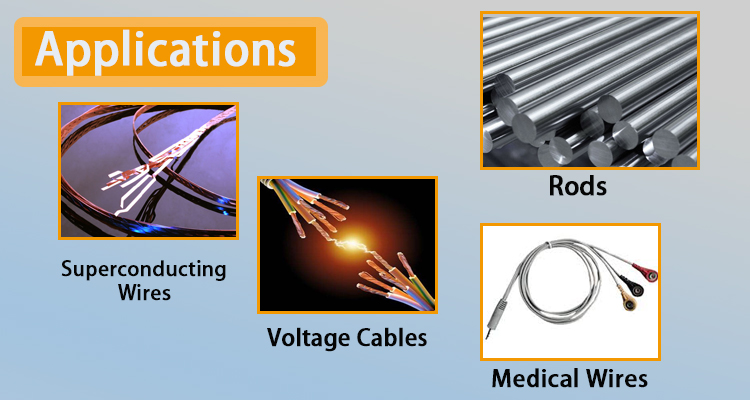

Applications of Wire Drawing in Various Industries: A Comparative Analysis

The Effect of Wire Drawing on the Mechanical Properties of Metal Parts

Wire Drawing as a Cost-Effective Surface Finishing Option for Manufacturing Industries

The Importance of Quality Control in Wire Drawing Processes for五金配件

Case Studies: The Impact of Wire Drawing on the Performance of Hardware Components

The Future of Wire Drawing in the Context of Sustainable Manufacturing Practices

Advancements in Wire Drawing Technology and Their Implications for五金配件制造业

Revolutionizing Industrial Design with Enhanced Wire Drawing Finishes for Metal Parts

The Role of Wire Drawing in Enhancing the EnergyEfficiency of Metal Components

Wire Drawing Techniques for Optimizing the Production Process in Manufacturing Units

From Tooling to Process Control: Strategies for Effective Wire Drawing Management

The Influence of Environmental Factors on the Performance of Wire Drawn Metal Components

The Relationship Between Wire Drawing and Surface Roughness in Hardware Product Quality Assessments

Optimizing Wire Drawing Processes for Increased Productivity and Reduced Costs in Manufacturing Operations

An Overview of the History, Development, and Future Trends in Wire Drawing Technology for Metal Parts Manufacturing.

Articles related to the knowledge points of this article:

Goodhope Doors and Windows Hardware Fittings Pictures

National Standards for Hardware Fittings