How to Customize Metal Dimensions for Industrial Applications: A Comprehensive Guide

Customizing metal dimensions for industrial applications is a complex process that requires attention to detail and precision. This comprehensive guide covers the key considerations and steps involved in customizing metal dimensions. It starts by understanding the different types of metals commonly used in industrial applications, including their properties such as strength, corrosion resistance, and thermal conductivity. The guide then provides guidance on choosing the right type of metal based on the specific requirements of the application. Next, the guide explains the importance of accurate measurements and how to use specialized tools and techniques to measure and dimension metal parts accurately. It also discusses the factors that affect dimensional accuracy, such as material fatigue and thermal expansion. The guide then covers various methods of customization, such as drilling, sawing, milling, and turning. It provides detailed instructions on how to perform these operations safely and efficiently, taking into account factors such as tool selection, workpiece preparation, and safety measures. Finally, the guide concludes with tips for maintaining dimensional consistency throughout the manufacturing process, ensuring quality control and reducing waste. By following these guidelines, manufacturers can effectively customize metal dimensions for industrial applications while ensuring accuracy, efficiency, and safety.

In today's fast-paced and ever-evolving industrial sector, precision and efficiency are crucial. This is particularly true when it comes to metal products, where precise dimensions play a vital role in ensuring functionality, safety, and durability. However, customization can be a complex process, especially when it comes to metal dimensions. In this article, we will explore the various methods and considerations involved in customizing metal dimensions for industrial applications.

The Importance of Customizing Metal Dimensions for Industrial Applications

There are several reasons why customization is essential in the production of metal products for industrial use. One of the primary reasons is that different industries require different sizes and shapes of metal components. For example, in the automotive industry, precision metal parts are required for the manufacture of engines, transmissions, and other critical components. These parts must meet specific size and shape requirements to ensure proper functioning and safety.

Another reason for customization is to cater to the needs of individual customers or clients. In some cases, customers may have specific requirements for their metal products, such as unique shapes, sizes, or finishes. By offering customization options, manufacturers can meet these diverse needs and increase customer satisfaction.

Methods of Customizing Metal Dimensions for Industrial Applications

There are several methods used to customize metal dimensions for industrial applications. These include:

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD software allows engineers to design metal products with precise dimensions and shapes. Once the design is complete, it can be exported to a CAM system for further processing. The CAM system then generates tool paths and instructions for manufacturing the product using specialized machines and tools. This method ensures high accuracy and efficiency during the production process.

3D Printing: Another popular method for customizing metal dimensions is through 3D printing. This technology involves creating a digital model of the desired product and then using a 3D printer to produce it layer by layer. 3D printing offers high flexibility and can produce complex shapes and intricate designs with high precision.

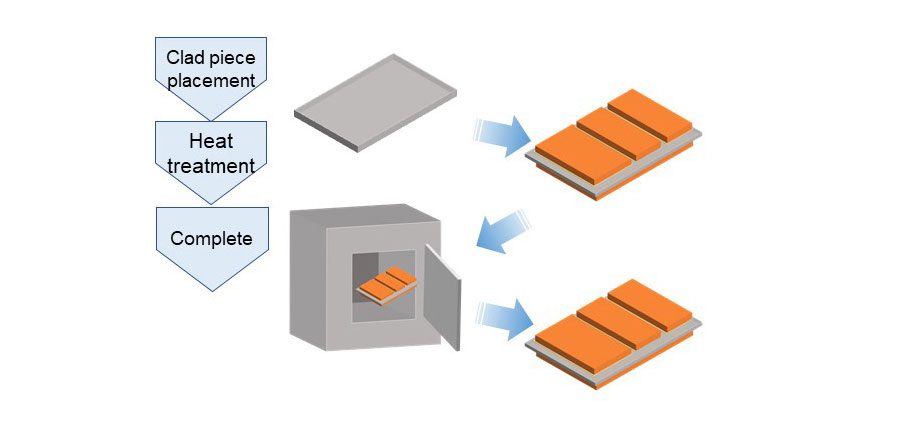

Metal Forming: Metal forming involves shaping metal materials using specialized tools and techniques. This method can produce large volumes of customized metal components quickly and cost-effectively. Common forms of metal forming include bending, stamping, spinning, drawing, and cutting.

Factors to Consider When Customizing Metal Dimensions for Industrial Applications

When customization is necessary for metal products in industrial settings, several factors must be considered to ensure success. These factors include:

Material Selection: Choosing the right metal material is critical for achieving the desired dimensions and performance. Different metals have distinct properties, such as strength, corrosion resistance, and heat conductivity. Therefore, it is essential to select a material that meets the specific requirements of the application.

Design Accuracy: Accurate design is essential for producing high-quality metal products with precise dimensions. Designers must consider factors such as tolerances, surfacefinishes, and structural integrity when creating the initial design. Additionally, they should verify the design using computer-aided engineering (CAE) tools to ensure accuracy before proceeding to the next step.

Production Methodology: The chosen production method will determine how accurately the dimensions can be achieved. Factors such as machine capabilities, production capacity, and labor availability must be considered when selecting a production methodology.

Cost Considerations: While customization may offer benefits such as increased efficiency and customer satisfaction, it may also increase costs due to the need for specialized tools and techniques. Manufacturers must balance these costs against the potential benefits of customization to make informed decisions about which methods to use. Conclusion

In conclusion, customizing metal dimensions is an essential aspect of producing high-quality industrial metal products

Articles related to the knowledge points of this article:

Custom Metal Packaging Bags: The Ultimate Solution for Product Protection and Branding

Title: Custom Metal Fabrication for a Range of Applications

Title: Customizing Hardware Checklist Template for Effective Project Management

Title: Custom Metalworking Factory in Foshan: A Comprehensive Guide