A Comprehensive Encyclopedia of Metalware Accessories

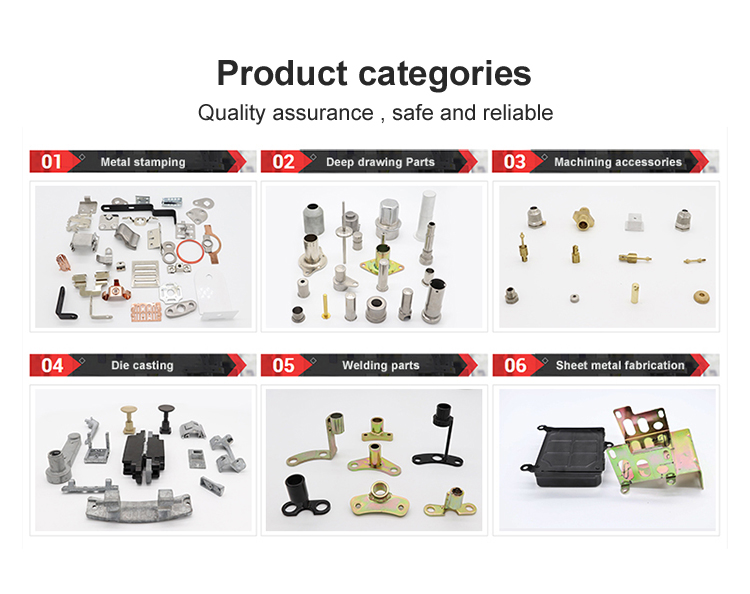

The Comprehensive Encyclopedia of Metalware Accessories is a comprehensive guide to metalware accessories, including their history, types, and uses. This encyclopedia covers a wide range of metalware accessories, including handles, brackets, hooks, and more. It also provides detailed information on the different materials used in metalware accessories, such as brass, copper, and stainless steel. The encyclopedia explains the significance and cultural importance of metalware accessories in various regions around the world, highlighting their role in traditional crafts and modern design. It also discusses the manufacturing process of metalware accessories, including casting, forging, and welding techniques. In addition, the encyclopedia offers practical tips for selecting and using metalware accessories in various applications, from home improvement to industrial settings. Overall, the Comprehensive Encyclopedia of Metalware Accessories is an invaluable resource for anyone interested in learning about metalware accessories and their many uses.

Metalware accessories are an integral part of our daily lives, playing a crucial role in the functioning and aesthetic appeal of various objects. They come in different shapes, sizes, and materials, each with its unique properties and applications. This article aims to provide a comprehensive guide to metalware accessories, covering their definitions, types, functions, manufacturing processes, and future trends.

Definition and Types of Metalware Accessories

Metalware accessories refer to the additional components added to metal products during the manufacturing process to enhance their functionality, appearance, or durability. They can be classified into several categories based on their characteristics, including shape, size, material, and purpose. Some common types of metalware accessories include:

1. Screws and Bolts: These are fasteners used to join two or more metal parts together. They come in different lengths, threads, heads, and materials (such as steel, brass, or bronze) to cater to various applications.

2. Nuts and Washers: These are mechanical components used to secure or isolate moving parts in mechanical systems. They come in different sizes, shapes, and materials (such as brass, chrome, or nylon) to ensure proper alignment and vibration reduction.

3. Castings and Die Castings: These are solid metal parts produced by casting or die casting processes using various materials such as iron, aluminum, zinc, or copper. They are used in various industries for their precision, durability, and corrosion resistance.

4. Drilled Holes and Slotted Parts: These are machined components used to allow movement or passage of fluids or gases between two or more metal surfaces. They come in different shapes, sizes, and depths depending on the application.

Functions of Metalware Accessories

Metalware accessories play a vital role in enhancing the performance, reliability, and aesthetics of metal products. They can be classified into several categories based on their functions, including:

1. Fasteners: Screws and bolts are essential fasteners that hold metal components together securely. They prevent loosening and deformation of the assembly due to vibration, pressure, or temperature changes.

2. Spacers and Retainers: These components are used to maintain a specific distance between two or more metal parts while allowing them to move smoothly. They help reduce friction, wear and tear, and improve the overall function of the system.

3. Seals and Gaskets: These components are used to prevent the entry of contaminants, fluids, or gases into sensitive areas of metal products. They come in different shapes, sizes, and materials (such as rubber, silicone, or polyurethane) depending on the application.

4. Connectors and Interface Devices: These components are used to connect or interface different types of metal components with each other. They come in different shapes, sizes, and standards (such as USB, HDMI, or Ethernet) depending on the application.

Manufacturing Processes of Metalware Accessories

Metalware accessories can be produced using various manufacturing processes that involve different steps and techniques. The choice of manufacturing process depends on the type of accessory, material availability, cost constraints, and quality requirements. Some common methods include:

1. Machining: This is a subtractive manufacturing process that involves cutting away unwanted metal from a workpiece using a variety of tools such as lathes, mills, and drills. Machining can produce complex shapes and sizes of metal parts with high accuracy and surface finish.

2. Casting: This is a constructive manufacturing process that involves pouring molten metal into a mold cavity to form a solid part with desired shape and dimensions. Casting can produce large quantities of identical or customized metal parts with low labor costs but may have limitations on size and shape flexibility.

3. Welding: This is a fusion manufacturing process that involves joining two or more metal parts using heat and pressure generated by a welding torch or an electric arc furnace. Welding can produce strong and durable joints that can withstand high loads and temperatures but may have limitations on size flexibility and surface finish.

Future Trends in Metalware Accessories

The demand for metalware accessories is expected to continue growing due to their versatility

Articles related to the knowledge points of this article:

Customizing Hardware Accessories: A Detailed Look into the Process

Title: Curtain Wall Hardware Fittings

National Strong Hardware Fittings

Title: Crafting Custom Hardware Accessories in Huaian: A Comprehensive Guide to Pricing