Exploring the Versatility and Efficiency of Metals Wholesale Furnace Systems

Wholesale furnace systems are a vital component in the metalworking industry, serving as a central hub for heating and melting various metals. These systems have undergone significant advancements in recent times, enhancing their versatility, efficiency, and reliability. The latest furnace technologies incorporate advanced sensors, control systems, and automation features, which allow for precise temperature control and optimization of energy consumption. Additionally, these systems are designed to operate at high temperatures, enabling them to melt a broader range of metals, including those with complex chemical properties.The versatility of wholesale furnace systems extends beyond their ability to melt different metals; they are also suitable for various industrial processes such as annealing, quenching, and tempering. This flexibility makes them ideal for use in a wide range of applications, including manufacturing, aerospace, and automotive industries. Furthermore, the efficient operation of these systems results in reduced energy consumption and waste generation, contributing to cost savings and environmental sustainability.In summary, the development of advanced wholesale furnace systems has transformed the metalworking industry by increasing their versatility, efficiency, and reliability. These systems are now essential components in various industrial processes and play a critical role in meeting the growing demand for precision manufacturing. As technology continues to evolve, it is anticipated that these systems will become even more sophisticated, further enhancing their performance and applicability in various industrial sectors.

Introduction:

In the realm of industrial manufacturing, the importance of efficient heating systems cannot be overstated. One such system that has proven to be highly effective in meeting the demands of the metalworking industry is the wholesale furnace. This article aims to provide a comprehensive overview of the various aspects of metal wholesale furnaces, including their design, functionality, and applications, as well as their contribution to the overall productivity and profitability of manufacturing operations.

Section 1: Design and Functionality of Metal Wholesale Furnaces

1、1 Overview of Metal Wholesale Furnaces

Metal wholesale furnaces are specialized equipment used for heating and melting metals in large quantities. They are designed to withstand high temperatures and ensure consistent heat distribution throughout the furnace. The furnace is typically composed of a chamber where the metal is placed, a heat source (such as an electric or gas-fired furnace), and a control system that monitors and regulates the temperature inside the furnace.

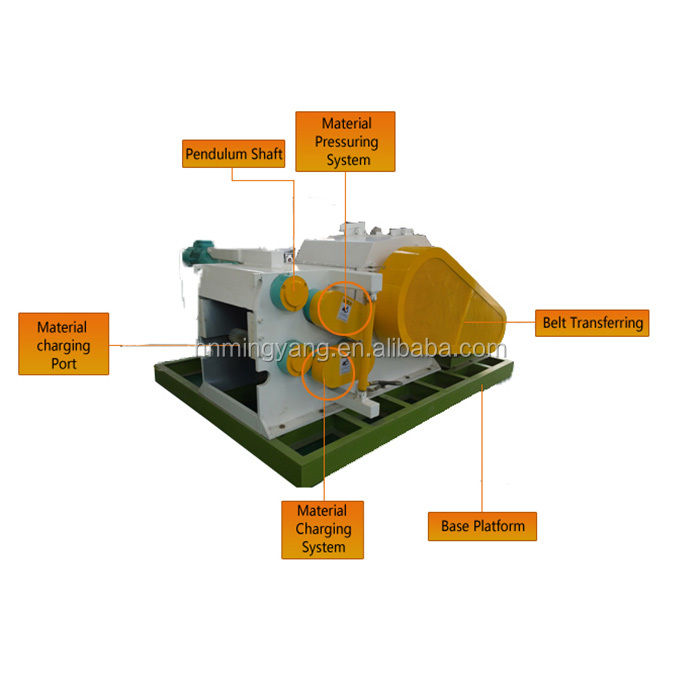

1、2 Key Components of Metal Wholesale Furnaces

a) Heating Source: The primary function of a heating source is to provide heat to the metal being melted. There are several types of heating sources available, including electric furnaces, gas-fired furnaces, and arc furnaces. Each type has its own advantages and disadvantages, depending on factors such as cost, energy efficiency, and ease of operation.

b) Control System: The control system is responsible for maintaining and regulating the temperature inside the furnace. It typically includes sensors that monitor the temperature of the metal being melted, as well as thermostats that adjust the heat output according to the desired temperature range. The control system may also include additional features such as automatic shutdown mechanisms and safety interlocks to prevent accidents.

c) Chamber: The chamber is where the raw metal is placed before it is heated and melted. It is typically made of materials such as stainless steel or cast iron, which can withstand high temperatures and protect the metal from damage during the melting process. The size of the chamber depends on the volume of metal being processed and the size of the furnace itself.

d) Air Flow System: An air flow system is necessary to ensure proper ventilation within the furnace and prevent build-up of dust and other particles that could contaminate the molten metal. The air flow system typically includes fans or blowers that distribute air throughout the chamber and remove any debris that may have accumulated.

1、3 Advantages and Disadvantages of Metal Wholesale Furnaces

a) High Temperature Capacity: One of the key advantages of metal wholesale furnaces is their ability to maintain high temperatures for extended periods of time. This makes them ideal for processing large volumes of metal quickly and efficiently.

b) Precision Control: The advanced control systems used in metal wholesale furnaces allow for precise temperature control, ensuring that each batch of metal is melted to the desired specifications. This helps to reduce waste and improve product quality.

c) Cost-effective: Although metal wholesale furnaces can be expensive to purchase and maintain, they offer significant cost savings over time due to their high efficiency and ability to process large volumes of metal quickly. Additionally, they require less labor compared to traditional methods, further reducing operating costs.

d) Safety Features: Metal wholesale furnaces are designed with safety in mind, featuring numerous interlocks and automatic shutoffs to prevent accidents caused by malfunctioning equipment or improper handling of hot materials. These features help to minimize risk and ensure a safe working environment for operators.

Section 2: Applications of Metal Wholesale Furnaces in Industrial Manufacturing

2、1 General Applications

Metal wholesale furnaces have a wide range of applications in industrial manufacturing, including:

a) Steel Fabrication: Steel fabrication involves shaping raw steel into various shapes and sizes for use in construction, automotive, or other industries. Metal wholesale furnaces are commonly used in this process to melt large quantities of steel for casting or other applications.

b) Aluminium Fabrication: Aluminium is a versatile material used in a variety of industrial applications, including aerospace, construction, and automotive industries. Metal wholesale furnaces are essential for producing aluminum products such as extrusions, sheets, and bars.

c) Brass Fabrication: Brass is a popular alloy used in jewelry making, plumbing, and other industrial applications. Metal wholesale furnaces are essential for processing brass scrap into new products or melting brass wire for production purposes.

d) Copper Fabrication: Copper is a valuable metal used in electrical wiring, plumbing fixtures, and other industrial applications. Metal wholesale furnaces are crucial for smelting copper ore into pure copper or processing copper scraps into new products.

e) Other Metal Applications: In addition to these common applications, metal wholesale furnaces can also be used for processing other metals such as zinc, lead, nickel, and tin. They are particularly useful for manufacturers seeking to reduce waste and improve efficiency in their operations.

Articles related to the knowledge points of this article:

Hardware Nails Wholesale Guide

Title: Discovering the Wonders of Kunshan Hardware Wholesale Market

Three Stone Hardware Wholesale: Quality and Cost-Effective Solutions for Your Hardware Needs