Mastering Metalworking: A Comprehensive Tutorial on Custom Metal Fabrication

In this comprehensive tutorial on custom metal fabrication, mastering metalworking is essential. This guide covers various aspects of metalworking, including safety measures, basic tools, cutting techniques, welding techniques, and finishing techniques. The tutorial also delves into the design process for creating unique metal products.The first section of the tutorial focuses on safety measures. It emphasizes the importance of proper personal protective equipment, such as gloves and goggles, when working with metal. The section also discusses how to avoid common hazards, such as cutting through fingers or getting burned by sparks.The second section covers basic tools and their functions. It provides an overview of common metalworking tools, such as a hammer, chisel, and saw. The section also explains how to use each tool effectively and safely.In the third section, the tutorial covers cutting techniques, including straight cuts, bevels, chamfers, and miter cuts. The section also discusses how to sharpen tools and maintain their edge.The fourth section focuses on welding techniques. It covers the different types of welding, such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Submerged Arc Welding (SAW). The section also explains how to set up a welder and adjust settings correctly.The final section of the tutorial covers finishing techniques. It discusses how to smoothen edges, polish surfaces, and add details to metal products using sanding, grinding, and painting techniques.Overall, mastering metalworking requires knowledge of safety measures, basic tools and cutting techniques, welding techniques, and finishing techniques. By following this comprehensive tutorial, anyone can learn the basics of custom metal fabrication and create unique metal products.

Introduction to Metalworking and Custom Fabrication

Metalworking is a versatile manufacturing process that involves cutting, shaping, and joining metal materials using various tools and techniques. Custom metal fabrication, on the other hand, is the process of creating unique and customized metal products tailored to specific customer requirements. This tutorial provides an in-depth exploration of metalworking, covering the basics of the industry, common metals used, and the different types of custom metal fabrication services available. By the end of this comprehensive guide, you will have a solid understanding of how to create custom metal products that meet your specific needs.

Chapter 1: Introduction to Metalworking

1、1 Metalworking Industry Overview

The metalworking industry has a long history, dating back to ancient civilizations when metals were first discovered and utilized for their inherent properties. Today, metalworking is a vital part of modern manufacturing, providing the foundation for countless products used in industries such as automotive, aerospace, construction, and more. In this chapter, we will explore the basic concepts and principles behind metalworking, including its history, evolution, and current state.

1、2 Common Metals Used in Metalworking

There are a wide variety of metals used in metalworking, each with its unique properties and applications. In this section, we will introduce some of the most commonly used metals in metalworking and discuss their characteristics, including strength, ductility, corrosion resistance, and cost.

1、3 Types of Metalworking Processes

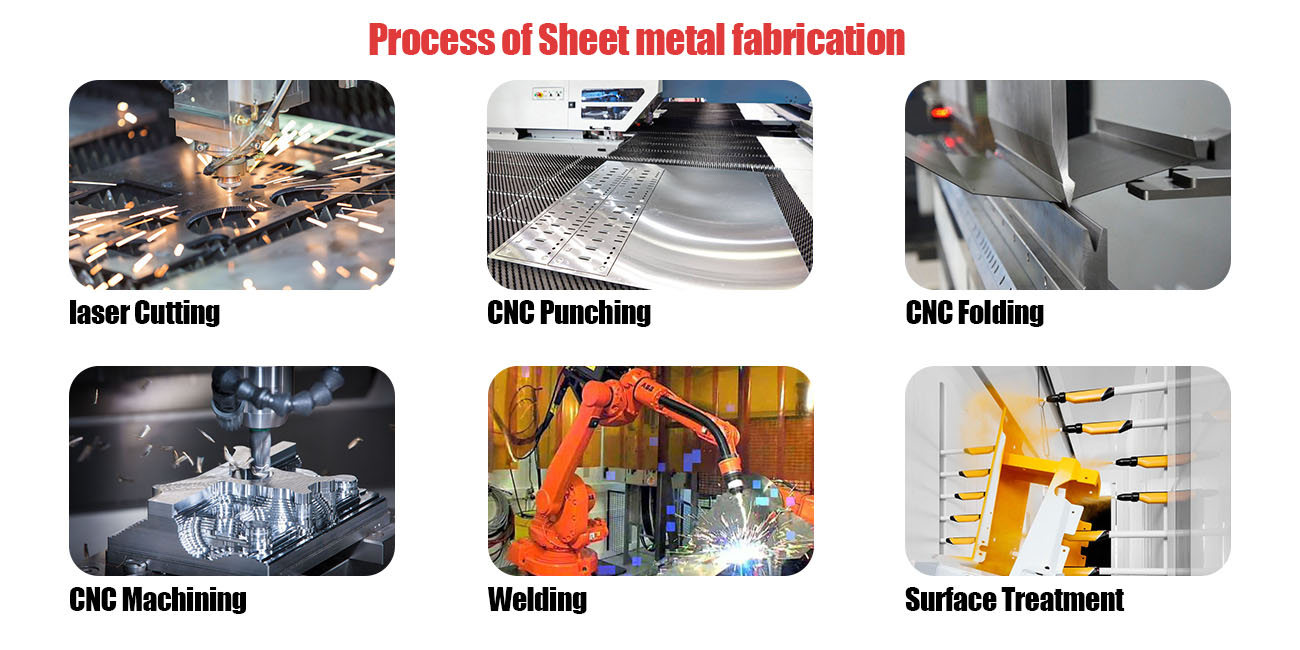

There are several methods used in metalworking, each with its advantages and disadvantages. Some of the most common processes include sawing, drilling, milling, lathing, welding, and bending. In this section, we will provide an overview of each process, highlighting its key features and applications.

Chapter 2: Basics of Custom Metal Fabrication

2、1 What is Custom Metal Fabrication?

Custom metal fabrication refers to the process of creating unique and customized metal products tailored to specific customer requirements. This may involve working with a variety of metals, including steel, aluminum, brass, copper, and more. The goal of custom metal fabrication is to produce high-quality products that meet the specific needs and preferences of the customer.

2、2 Benefits of Custom Metal Fabrication

There are many benefits associated with custom metal fabrication, including increased efficiency, flexibility, and customization options. By working closely with customers to understand their specific requirements, custom metal fabricators can deliver products that meet their exact needs and exceed their expectations. Additionally, custom metal fabrication often allows for greater control over the production process, allowing for greater precision and quality control.

2、3 Materials Selection in Custom Fabrication

The choice of materials used in custom metal fabrication can have a significant impact on the final product's performance, appearance, and cost. In this section, we will discuss factors to consider when selecting materials for custom metal fabrication projects, including strength requirements, corrosion resistance, cost, and aesthetic appeal.

Chapter 3: Common Techniques in Custom Metal Fabrication

3、1 Cutting Techniques in Custom Fabrication

Cutting is an essential technique in custom metal fabrication, enabling the creation of precise shapes and patterns from raw materials. Common cutting techniques include sawing (using a saw blade), drilling (using a drill press or CNC machine), and milling (using a vertical milling machine). Each technique has its strengths and limitations, and choosing the right one depends on the specific requirements of the project.

3、2 Joining Techniques in Custom Fabrication

Joining techniques are used to connect different parts or sections of a custom metal product. There are several methods used in custom metal fabrication, including spot welding, brazing, soldering, casting, and forging. Each method has its advantages and disadvantages, and choosing the right one depends on the specific requirements of the project.

3、3 Shaping Techniques in Custom Fabrication

Shaping techniques are used to modify the shape of raw materials into finished products. Common shaping techniques include bending (using a press or vise), spinning (using a lathe), and punching (using a punch press or CNC machine). Each technique has its strengths and limitations, and choosing the right one depends on the specific requirements of the project.

Articles related to the knowledge points of this article:

Customized Metal Labeling Machine in Foshan

Title: Custom Metal Fabrication in Hebei, China