Custom Metal Stamping Presses: All You Need to Know

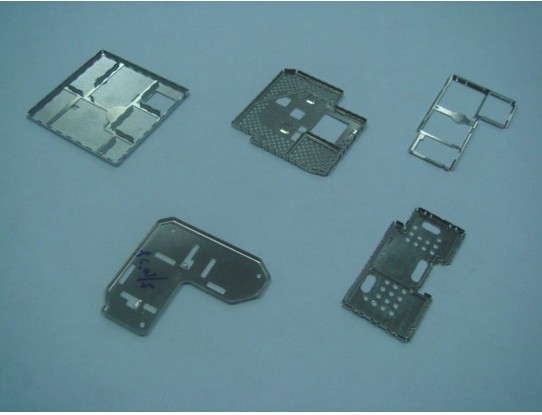

Custom Metal Stamping Presses are machines that are specifically designed to stamp metal parts into specific shapes or patterns. These presses are typically used in manufacturing or industrial settings to produce metal components that are required for various applications. Custom Metal Stamping Presses have several advantages that make them a cost-effective and efficient solution for metal processing needs. They can be designed to produce a wide range of metal parts, from simple to complex shapes, and can accommodate different metal materials and thicknesses. Additionally, these presses can be customized to meet specific production requirements, such as stamping speed, precision, and volume. Custom Metal Stamping Presses also offer a high level of versatility and can be easily integrated into existing manufacturing processes. They can be used to stamp metal parts that are subsequently used in other manufacturing operations, such as machining, grinding, or assembly. This integration helps to streamline the manufacturing process and improve overall efficiency. In conclusion, Custom Metal Stamping Presses are essential machines for any metal processing operation. They provide a cost-effective and efficient solution for producing metal parts with precision and speed, while also offering a high level of versatility and integration with other manufacturing processes.

Metal stamping presses, also known as stamping machines, are crucial pieces of equipment in the metalworking industry. They are used to shape metal pieces by applying pressure to them. Whether you need to produce metal parts for automotive, aerospace, or other applications, a custom metal stamping press can significantly enhance your productivity and efficiency.

What is a Custom Metal Stamping Press?

A custom metal stamping press is a machine that is designed and built to meet specific requirements of a particular application. These presses are tailored to the shape, size, and material of the metal pieces being processed. By contrast, standard metal stamping presses are designed to work with a range of applications and materials but may not be optimized for any specific task.

Why Use a Custom Metal Stamping Press?

There are several advantages to using a custom metal stamping press over a standard one. Firstly, a custom press can be designed to match the specific dimensions and shape of the metal pieces being processed, reducing the need for costly and time-consuming modifications to standard equipment. This ensures that each metal piece is processed precisely according to its unique specifications.

Secondly, a custom metal stamping press can be optimized for the specific material being used. By adjusting the pressure, speed, and other parameters, a custom press can ensure optimal performance and maximize the efficiency of the material usage. This not only helps to reduce waste but also increases the quality of the final product.

Thirdly, a custom metal stamping press can be equipped with advanced features and technology that are tailored to the specific application. For example, it may include automated loading and unloading systems, computer-controlled precision positioning, and other advanced capabilities that significantly enhance productivity and reduce operator intervention.

How Much Does a Custom Metal Stamping Press Cost?

The cost of a custom metal stamping press depends on several factors, including the complexity of the design, the materials used, and the level of automation desired. Simple custom presses may cost less than standard equipment, while more complex and highly automated presses can cost significantly more. It is important to work with a reputable manufacturer or supplier to ensure that you receive a high-quality and cost-effective solution tailored to your specific needs.

In conclusion, a custom metal stamping press can provide numerous advantages over standard equipment by matching the unique requirements of your application. By working with a manufacturer to design and build a press tailored to your specific needs, you can significantly enhance productivity, efficiency, and product quality.

Articles related to the knowledge points of this article:

Top 10 Brands for Customized Hardware Products

Customized Yongzhou Hardware Processing

Title: Anhui Customized Hardware Prices

Title: Average Prices of Custom Hardware in Miyun District

Title: Replacing Custom Wardrobe Hardware: A Comprehensive Guide