Unlocking the Potential of Metalworking: The Evolution of CNC Machine Tools in Hardware Assembly

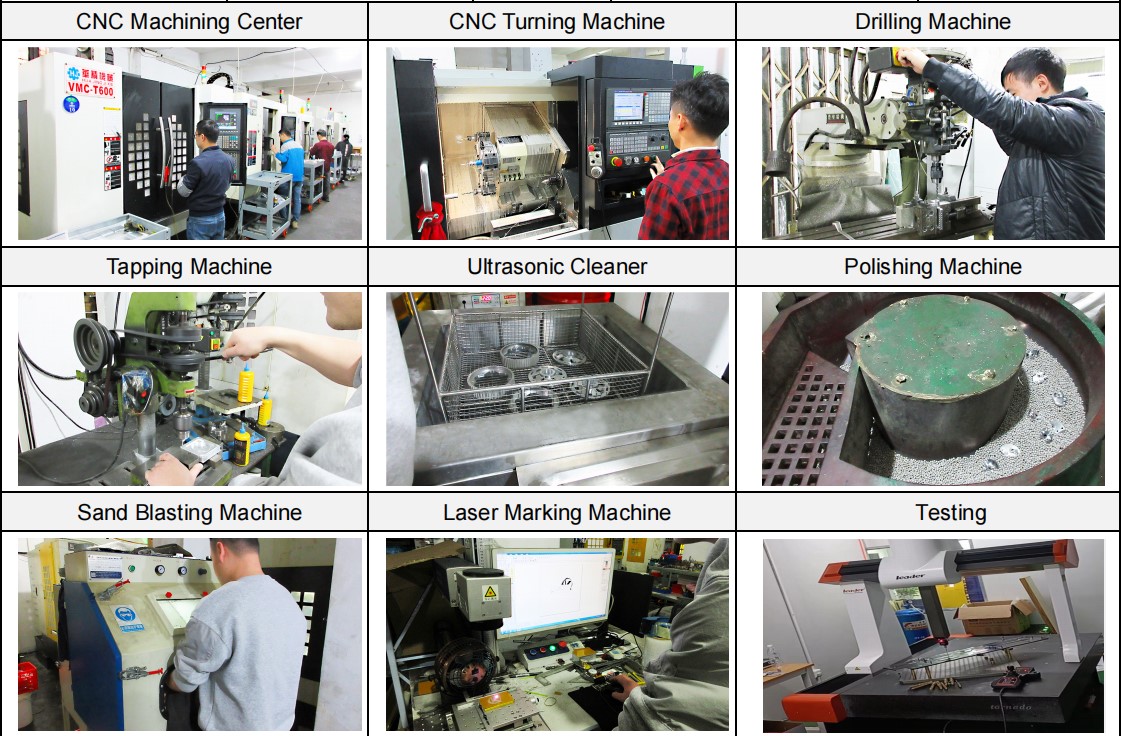

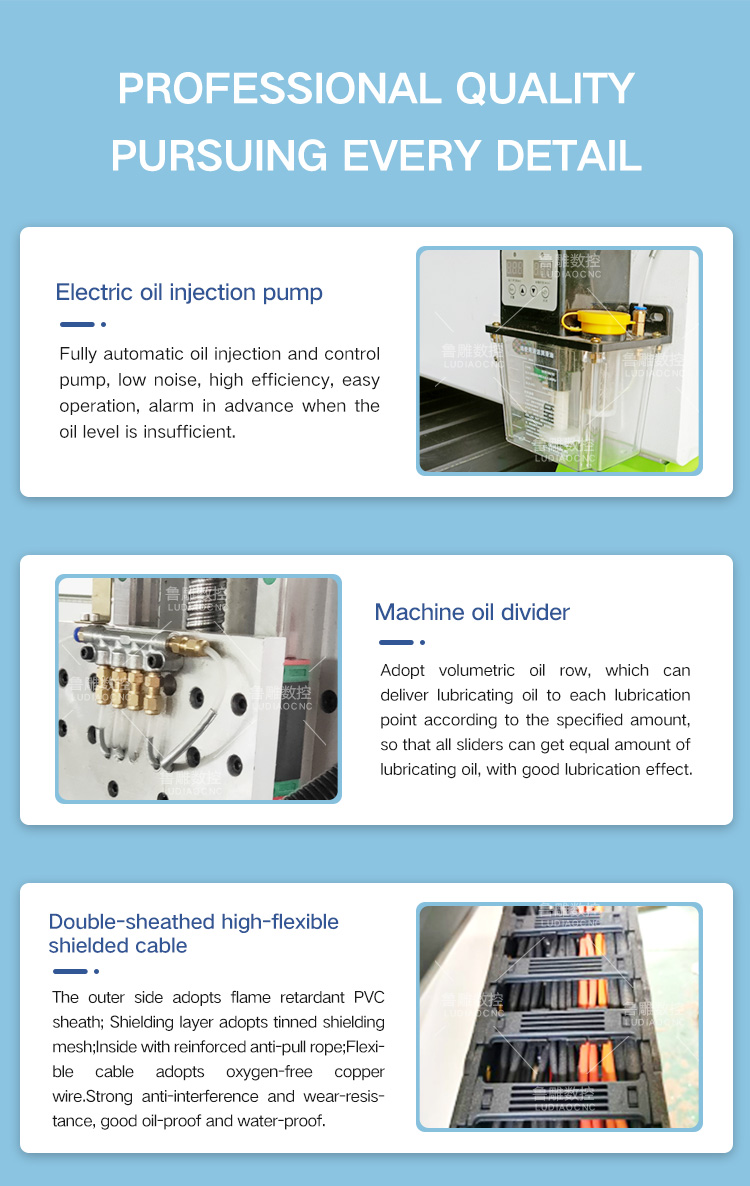

CNC machine tools have been a game-changer in the metalworking industry. They have revolutionized the way hardware is assembled, making it faster, more precise, and cost-effective. The evolution of CNC machine tools has unlocked the potential of metalworking by enabling manufacturers to produce complex shapes and designs with ease.The early versions of CNC machines were limited in their capabilities but with advancements in technology, CNC machines have become more advanced and versatile. They can now handle larger parts, work on multiple materials, and operate at higher speeds than ever before. This has led to increased productivity and efficiency in the production process.One of the key advantages of CNC machines is their ability to program complex designs. With computer numerical control (CNC), manufacturers can create detailed blueprints that can be fed into the machine for execution. This not only saves time but also reduces errors and waste.Moreover, CNC machines are highly customizable. Manufacturers can tailor them to specific needs, making them ideal for applications such as aerospace, automotive, and medical devices.In conclusion, the evolution of CNC machine tools has unlocked the full potential of metalworking. From simple machines to advanced systems, CNC machines have transformed the way hardware is assembled, improving productivity, efficiency, and quality. As technology continues to advance, we can expect even more innovative solutions from CNC machine tools in the future.

In today's modern manufacturing industry, precision and efficiency are crucial to achieving success. One area where these two principles have been particularly impactful is in the field of metalworking, specifically within the realm of hardware assembly. The use of Computer Numerical Control (CNC) machine tools has revolutionized the way metal parts are manufactured, making it possible to produce high-quality components with incredible accuracy and speed. In this article, we will explore the fascinating world of CNC machine tools and their role in shaping the future of hardware assembly.

1、The Evolution of CNC Machines

CNC technology has its roots in the early 20th century, when engineers began experimenting with automated machines that could perform complex calculations and repetitive tasks. However, it was not until the late 1940s and 1950s that the first commercial CNC machines were developed, thanks to advancements in electronic and mechanical engineering. These early machines were primarily used for cutting and drilling wood and plastics, but they laid the foundation for a new generation of industrial machinery.

The following decades saw rapid advances in CNC technology, as manufacturers sought to develop more powerful and versatile machines capable of handling a wider range of materials and tasks. In the 1960s, numerical control systems became more sophisticated, allowing for greater precision and control over machine movements. The 1970s saw the introduction of computer-aided design (CAD) software, which enabled engineers to design complex components using computer-generated models. This technology paved the way for the development of more advanced CNC machines in the 1980s and 1990s.

2、The Role of CNC Machines in Hardware Assembly

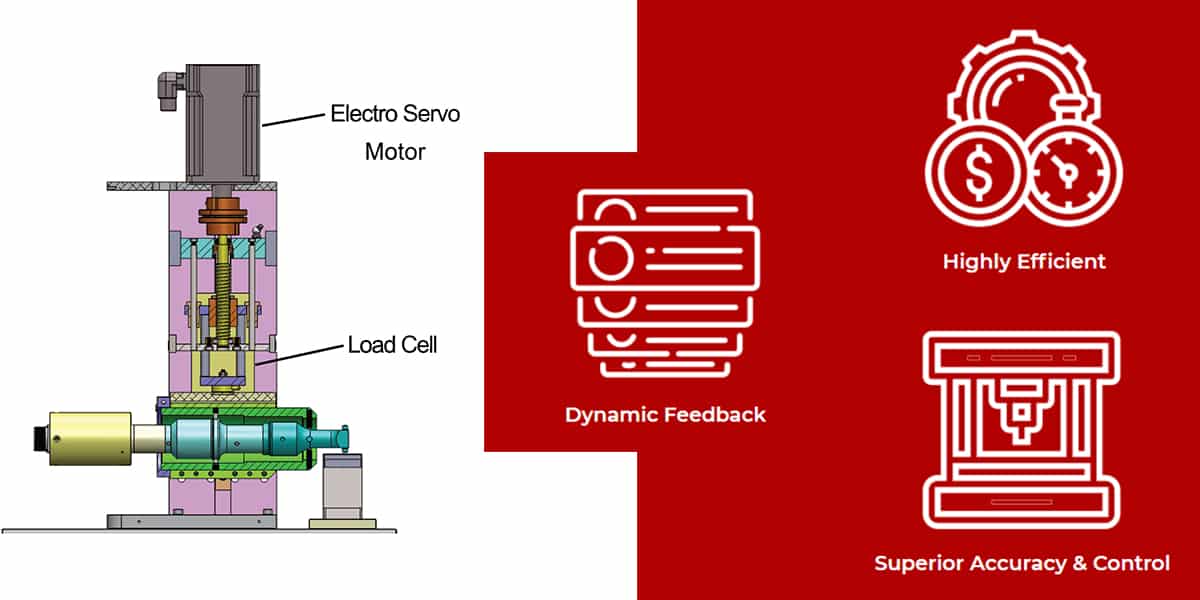

One area where CNC machines have had a particularly significant impact is in the field of hardware assembly. By utilizing computerized control systems and specialized tooling, CNC machines can produce components with unparalleled accuracy and consistency. This makes them ideal for producing high-volume parts with tight tolerances, which are essential for many types of hardware applications.

Some common applications for CNC machined components include automotive parts, aerospace components, medical equipment, and consumer electronics. In each of these industries, precision is key, and CNC machines provide an efficient and cost-effective solution for meeting demanding performance requirements.

3、Advantages of CNC Machined Components

There are several advantages to using CNC machined components compared to traditional handcrafted parts. Perhaps the most significant benefit is precision – thanks to the high levels of accuracy achievable through CNC machining, components produced using this method can be far more precise than those created by hand. This makes them ideal for use in high-stress applications where even small differences in size or shape can have significant consequences.

Another advantage of CNC machined components is their consistent quality. Because every part is produced using the same set of specifications and processes, there is less room for error or variation between individual components. This can help to ensure that products meet strict quality control standards and maintain a consistent level of performance over time.

In addition, CNC machined components typically take less time to produce than handcrafted parts, as they can be programmed to perform specific tasks quickly and efficiently. This can lead to significant cost savings for manufacturers, especially in high-volume production environments.

4、The Future of CNC Machine Tools in Hardware Assembly

Despite the many advantages offered by CNC machine tools, there are still some challenges that need to be addressed if they are to be fully embraced by the hardware assembly industry. One of the biggest challenges is the high cost associated with acquiring and maintaining CNC machinery. While advances in technology have helped to reduce these costs in recent years, there is still work to be done to make CNC machines accessible to smaller businesses and hobbyists.

Another challenge is the lack of skilled labor available to operate and maintain CNC machines. As these technologies continue to evolve and become more advanced, it is becoming increasingly important for manufacturers to invest in training programs that can help to develop a new generation of skilled operators.

Despite these challenges, however, the future of CNC machine tools looks bright for the hardware assembly industry. As demand continues to grow for high-precision components across a wide range of industries, there will be increasing pressure on manufacturers to adopt these technologies if they want to remain competitive. By investing in CNC machine tools and developing new skills among employees, companies can position themselves at the forefront of this exciting evolution in hardware assembly.

Articles related to the knowledge points of this article:

Title: The Development Status of Advanced Metal Hardware Components in Suzhou

Title: Shenzhens Informationization of Hardware Parts Planning

Tent Hardware Accessories: An Essential Guide

The Advantages of Hardware Fittings

The rise of hardware accessories in 3D printing

Title: Competitive Pricing of Hardware Accessories in Hubei Province, China: A Market Analysis