Custom Hardware Manufacturing Process

The custom hardware manufacturing process is a crucial step in the development of any physical product. It involves the design, creation, and testing of unique hardware components that are tailored to specific applications or needs. The process begins with the identification of a problem or opportunity that can be addressed with custom hardware. Then, a design is created using computer-aided design (CAD) software to visualize the desired component. Once the design is approved, it is sent to a manufacturer who uses techniques such as machining, molding, or casting to create the physical component. The manufacturer then tests the component to ensure its quality and performance before delivering it to the customer. This entire process requires a significant amount of time, effort, and expertise to ensure that the final product meets all of the specified requirements and performs as expected.

The custom hardware manufacturing process is a crucial aspect of the production of unique and specialized equipment. This process involves a series of steps that ensure the creation of high-quality, durable, and functional hardware products tailored to specific applications. From concept to completion, each step in the process requires precision and attention to detail to ensure the final product meets the desired specifications and performance criteria.

The first step in the custom hardware manufacturing process is the design phase. This phase involves the creation of a detailed design plan that outlines the shape, size, and features of the hardware product. The design plan is typically based on the specific requirements and preferences of the customer, as well as the manufacturer's capabilities and resources. The use of computer-aided design (CAD) software is common during this phase to create three-dimensional models that visualize the final product.

Once the design phase is completed, the next step is the materials selection phase. In this phase, the manufacturer chooses the raw materials that will be used to create the hardware product. The selection of materials is crucial as it affects the product's durability, performance, and cost. The manufacturer may consider factors such as the material's mechanical properties, chemical resistance, and thermal stability to ensure the selected materials are suitable for the application.

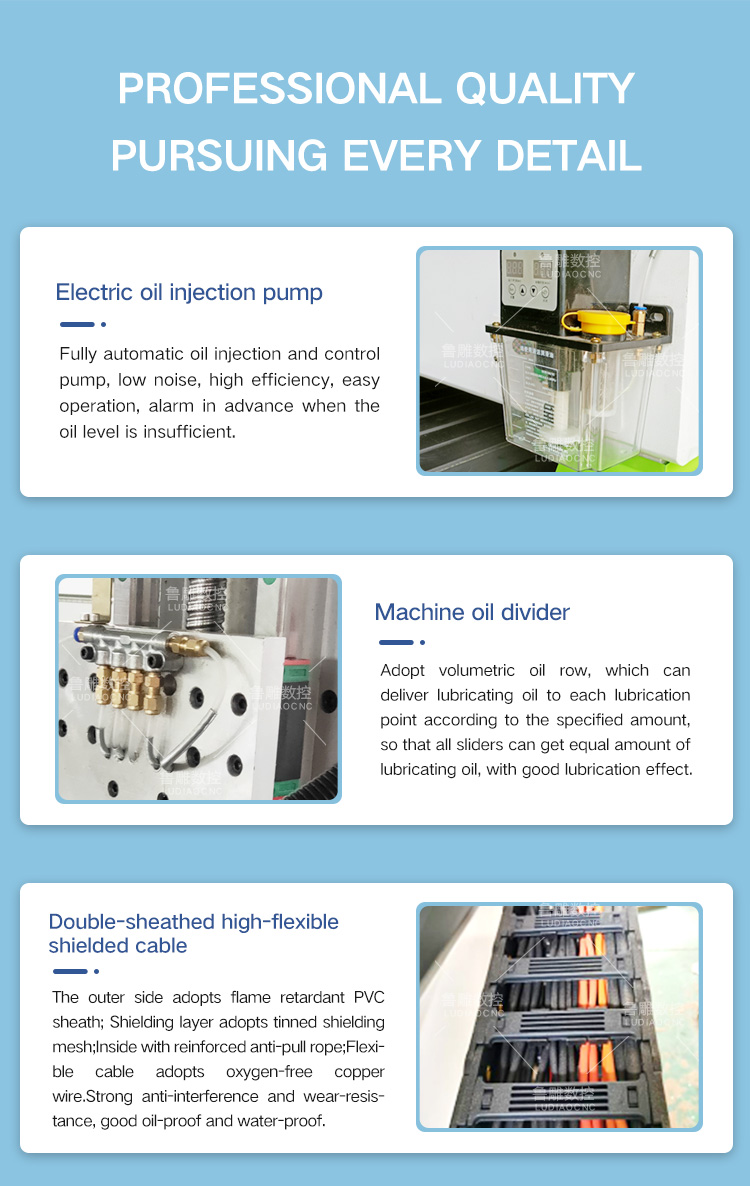

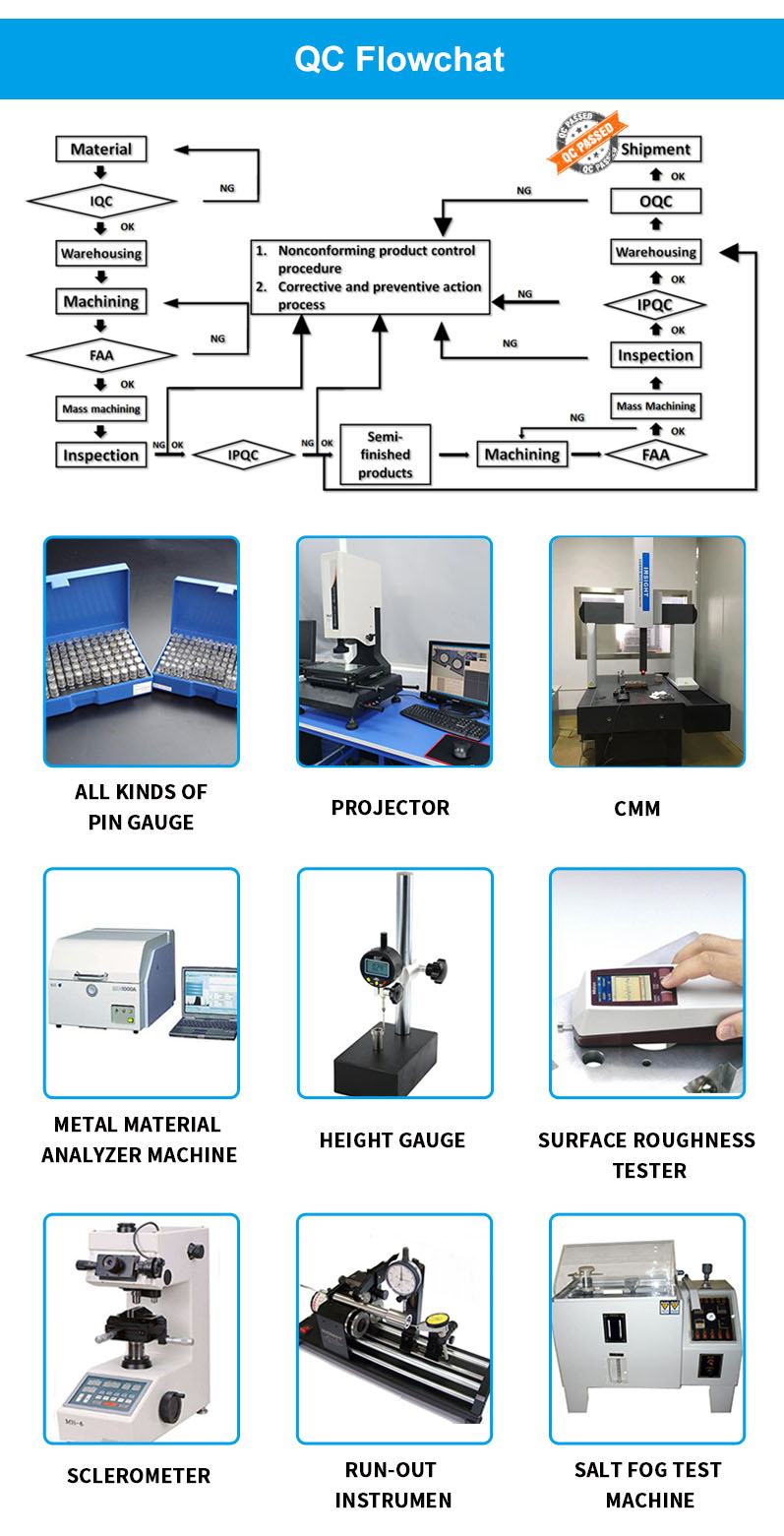

Following the materials selection phase, the manufacturer moves into the production phase. This phase involves the actual manufacturing of the hardware product using techniques such as machining, molding, or casting. The manufacturer ensures that each step in the production process is carefully controlled to ensure the product's quality and consistency. This phase also involves the use of quality control techniques to ensure that the product meets the specified standards and requirements.

Once the hardware product is manufactured, it moves into the testing phase. In this phase, the manufacturer performs various tests to evaluate the product's performance and durability. These tests may include mechanical tests such as tensile strength, compression strength, or fatigue tests to determine how well the product withstands stress and strain. Additionally, environmental tests may be conducted to evaluate how well the product performs in extreme temperatures, humidity, or vibration levels.

Once the testing phase is completed and the product has been approved for use, it moves into the packaging and distribution phase. In this phase, the manufacturer packages the product for transportation and storage, ensuring that it remains intact and protected from damage during transit. The packaging materials and methods are chosen based on the product's type, size, weight, and other factors that affect its transportability and protectiveness.

Finally, once the product reaches its destination, it is ready for use by the customer. The customer can then evaluate its performance and provide feedback to the manufacturer to help improve future products.

In conclusion, the custom hardware manufacturing process is a complex but crucial aspect of creating unique and specialized equipment that meets specific applications and requirements. By carefully controlling each step in the process and ensuring that each phase is completed to a high standard, manufacturers can create high-quality, durable, and functional hardware products that are tailored to their customer's needs.

Articles related to the knowledge points of this article:

Title: Embracing Quality and Customer-centricity: An Insight into Bejings Customized Hardware Stores

Customized Hardware Processing in Linhai

Zhenjiang Hardware Customization Market

Custom Hardware Solutions from YouDui

Title: Customized Heavy Metal Hardware in Neihuang: A Solution for All Your Needs