The Art of Steel Plant Hardware Wholesale: A Comprehensive Guide to Sourcing Quality Products

Steel plant hardware is a crucial component in the construction and maintenance of industrial facilities, power plants, and other large-scale engineering projects. However, finding reliable and high-quality suppliers can be a daunting task. This comprehensive guide aims to address this challenge by providing readers with essential information on how to source steel plant hardware wholesale. From identifying the right suppliers to evaluating their products and services, this article covers all the critical aspects of sourcing steel plant hardware. It also offers tips on negotiating pricing, ensuring delivery deadlines are met, and maintaining good relationships with suppliers over time. By following these guidelines, readers can save time, money, and effort in their search for the best steel plant hardware suppliers. Whether you are a seasoned industry professional or just starting out, this guide provides valuable insights that will help you succeed in the competitive world of steel plant hardware wholesale. So, whether you are looking to expand your business or simply purchase quality hardware for your project, this guide has got you covered.

Introduction

The steel plant industry is a vital component of modern manufacturing, providing the foundation for countless infrastructure projects and consumer products. At the heart of this industry lies the complex network of hardware suppliers and manufacturers, who work together to ensure that the steel plants can operate efficiently and effectively. This guide aims to provide an in-depth look at the world of steel plant hardware wholesale, exploring the key factors that impact supply, quality, and pricing, as well as offering practical tips and advice for businesses looking to establish a strong presence in this competitive market.

Chapter 1: Understanding the Steel Plant Hardware Supply Chain

Before diving into the specifics of wholesale hardware distribution, it is essential to have a solid understanding of the broader supply chain. At its most basic level, the steel plant hardware supply chain involves several key players, each with their own unique roles and responsibilities. These players include:

1. Raw Materials Suppliers: These are the companies responsible for providing the raw materials needed to manufacture steel plant hardware, such as metal alloys, plastics, and other synthetic materials.

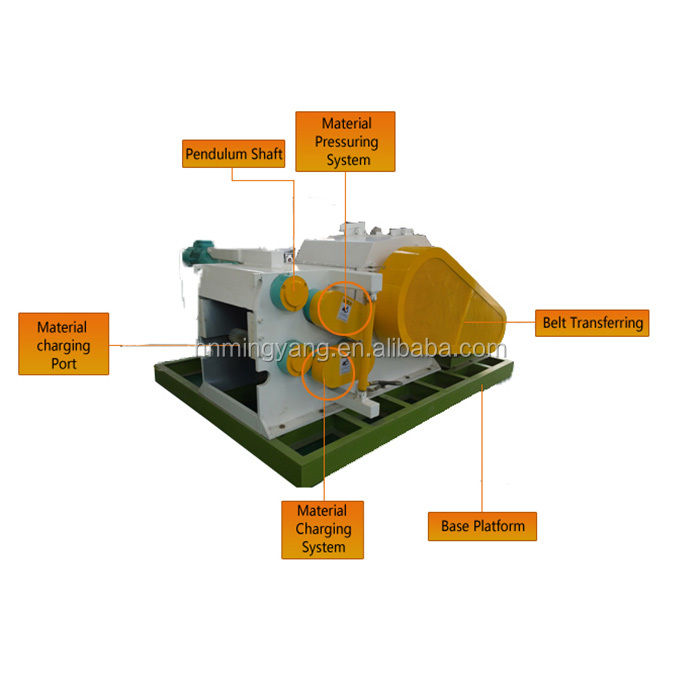

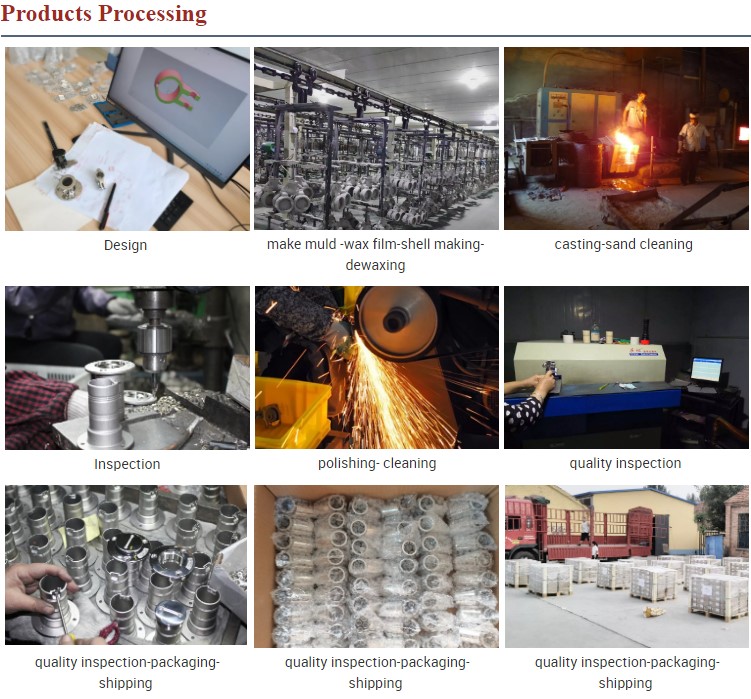

2. Manufacturers: These are the companies that convert raw materials into finished products using specialized machinery and skilled labor. Some manufacturers specialize in certain types of hardware, such as valves, fittings, or safety equipment, while others offer a more comprehensive range of products.

3. Wholesalers/Wholesale Distributors: These companies act as intermediaries between manufacturers and retailers, buying large quantities of hardware from manufacturers at discounted prices and then reselling them to smaller businesses or individual customers. Wholesale distributors typically have established relationships with both manufacturers and retailers, allowing them to negotiate better prices and pass along those savings to their customers.

4. Retailers/Distributors: These are the companies that sell hardware products directly to end-users, such as construction companies, maintenance technicians, or industrial engineers. Retailers may also act as wholesalers, selling hardware to smaller businesses or individuals in addition to larger customers.

Understanding the role of each player in the supply chain is crucial for businesses looking to navigate the world of steel plant hardware wholesale. By developing strong relationships with these players and staying informed about market trends and changes in demand, businesses can position themselves for success in this fast-paced and competitive industry.

Chapter 2: Key Factors Impacting Steel Plant Hardware Supply and Pricing

There are several key factors that can impact the availability of steel plant hardware products and their overall pricing. These factors include:

1. Raw Material Prices: The cost of raw materials used to manufacture steel plant hardware can fluctuate significantly over time, affecting both the availability of certain products and their overall pricing. For example, if nickel prices rise due to increased global demand or geopolitical tensions, the price of nickel-based alloys used in valve manufacturing may increase, putting pressure on manufacturers to increase prices for products made with those materials.

2. Global Economic Conditions: Economic conditions in countries where steel plant hardware is produced or exported can also impact supply and pricing. For example, a recession or economic downturn may lead to reduced demand for hardware products, causing some manufacturers to reduce production or raise their prices to compensate for reduced sales. In contrast, periods of economic growth may lead to increased demand for hardware products, driving up prices as manufacturers work to meet that demand.

3. Market Trends and Demand: Changes in industry trends and demand for specific types of hardware can also impact supply and pricing. For example, if there is a growing trend towards energy efficiency and sustainability in industrial settings, there may be increased demand for products designed to improve energy performance or reduce waste. This could lead to increased availability of certain types of hardware products at lower prices, as manufacturers respond to the changing market demand.

Chapter 3: Navigating the World of Steel Plant Hardware Wholesale

Navigating the world of steel plant hardware wholesale can be a complex and challenging process, requiring businesses to develop strong relationships with multiple partners across the supply chain and stay informed about market trends and changes in demand. However, by following some key best practices, businesses can position themselves for success in this competitive market:

1. Build Strong Relationships With Suppliers and Manufacturers: One of the most critical components of successful steel plant hardware wholesale is building strong relationships with suppliers and manufacturers. By establishing trust and working closely with these partners, businesses can negotiate better prices, gain access to exclusive products, and receive personalized service tailored to their specific needs.

2. Stay Up-to-Date on Industry Trends and Changes in Demand: Another key strategy for success in steel plant hardware wholesale is staying informed about industry trends and changes in demand for specific types of products

Articles related to the knowledge points of this article:

Exploring the Marvels of Linyi Metalware Wholesale Market: A Hub of Industrial Supply

Tianjin Hardware Wholesale Supply

Title: Alibaba五金批发网, Your One-Stop Solution for All Metal Products and Components