The Installation of Anti-Corrosion Glass and Hardware in a Woodworking Shop

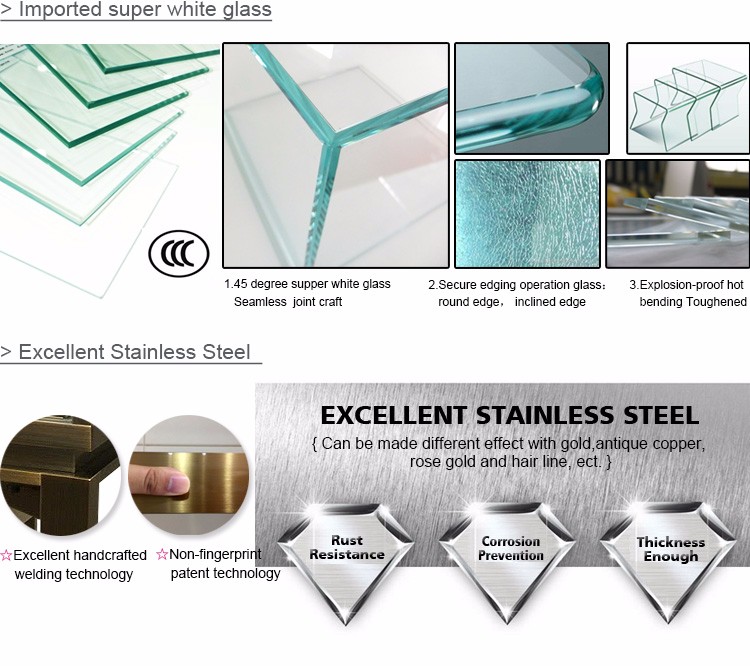

In a woodworking shop, the installation of anti-corrosion glass and hardware is crucial for the protection of the workshop environment and the tools stored within. The anti-corrosion glass, which is typically clear or tinted to protect the eyes from harmful UV rays, is installed over the workbench to shield the workspace from dust and debris. This glass also helps to reduce the spread of corrosion caused by moisture and other contaminants.The hardware, which includes nuts, bolts, and screws, is also essential for the workshop. It is used to assemble and disassemble tools and equipment, and its quality and performance directly affect the workshop’s output. Therefore, it is important to choose hardware that is resistant to corrosion and other environmental factors that could damage it. By installing anti-corrosion glass and hardware, a woodworking shop can ensure its longevity and efficiency.

In the bustling atmosphere of a woodworking shop, the installation of anti-corrosion glass and hardware is crucial for the preservation of the shop's tools and equipment. The process of installing the glass and hardware, however, can be quite challenging and requires a significant amount of expertise and care.

Firstly, the preparation of the surfaces is essential. The glass and hardware will be installed onto wooden surfaces, so it is important to ensure that these surfaces are smooth and free from debris or contaminants. This can be achieved by using sandpaper or a wood planer to level the surface and remove any rough edges.

Once the surfaces are prepared, the next step is to apply the anti-corrosion treatment. This treatment will help to protect the glass and hardware from the elements and ensure that they remain in good condition for longer. The treatment can be applied using a brush or a spray can, and it is important to ensure that all surfaces are evenly coated.

Once the anti-corrosion treatment has been applied, the glass can be cut to size using a glass cutter or a tile cutter. It is important to measure the size accurately to ensure that the glass fits snugly into the frame. The glass should be cleaned again before installation to remove any residue from the cutting process.

The installation of the glass and hardware can now commence. The glass is placed into the frame, and the hardware is attached using screws or bolts. It is important to ensure that the glass is properly supported and that there are no gaps or leaks around the edges. The hardware should be tightened securely to ensure that the glass remains in place.

Finally, the shop should be left to settle for a few days to allow the anti-corrosion treatment to fully cure and do its job. During this time, it is important to avoid any contact with water or other contaminants that could affect the treatment's effectiveness.

In conclusion, the installation of anti-corrosion glass and hardware in a woodworking shop is a crucial step in protecting the shop's tools and equipment from corrosion and other environmental factors. The process requires a significant amount of expertise and care, but it is well worth taking the time to do it properly. By following these steps, you can ensure that your shop's equipment remains in good condition for longer, increasing its lifespan and performance.

Articles related to the knowledge points of this article:

How to Open a Hardware Store: A Comprehensive Guide

Title: Is it Possible to Buy Second-Hand Clothes in a Hardware Store? The Truth Behind the Question

Gun and Hardware Store: The Story of Adhesive Gun and Its Impact on the Hardware Industry

Title: Opening a Large-Scale Hardware Store: A Comprehensive Guide

Title: Understanding the Cost of Engraving Stamps at Hardware Stores

Title: Understanding the Price Range for Plastic Flower Showers in Hardware Stores