Customize Hardware Parts in Taizhou: A Guide to Professional Metalwork

Taizhou, a city in China known for its metalworking industry, offers a wide range of customization options for hardware parts. With skilled craftsmen and advanced machinery, Taizhou has established itself as a hub for precision metalwork. Whether you need standard or custom-made hardware parts, Taizhou can provide high-quality results. The city's metalwork tradition dates back centuries, and it continues to thrive today due to its skilled workforce and modern equipment. From manufacturing small components to large-scale production, Taizhou's metalworkers can handle any project. They use state-of-the-art machinery to produce precise parts quickly and efficiently, while also paying attention to detail and ensuring quality control at each stage of the process. If you're looking for professional metalwork services in Taizhou, consider working with a local company that offers customized hardware parts. By working with experienced craftsmen, you can ensure that your project gets the attention it deserves and that the final product meets your specifications. With Taizhou's commitment to excellence, you can trust that your hardware parts will meet your needs and exceed your expectations.

In today's rapidly evolving world, precision and customization are highly valued in various industries. The manufacturing sector is not an exception, where customized hardware parts play a crucial role in ensuring the success of different projects. Taizhou, located in the southern part of China, is renowned for its exceptional metalworking expertise and has become a popular destination for businesses seeking high-quality custom hardware solutions. This article aims to provide an in-depth guide to Taizhou's hardware part customization, covering everything from the process to common types of materials and popular applications.

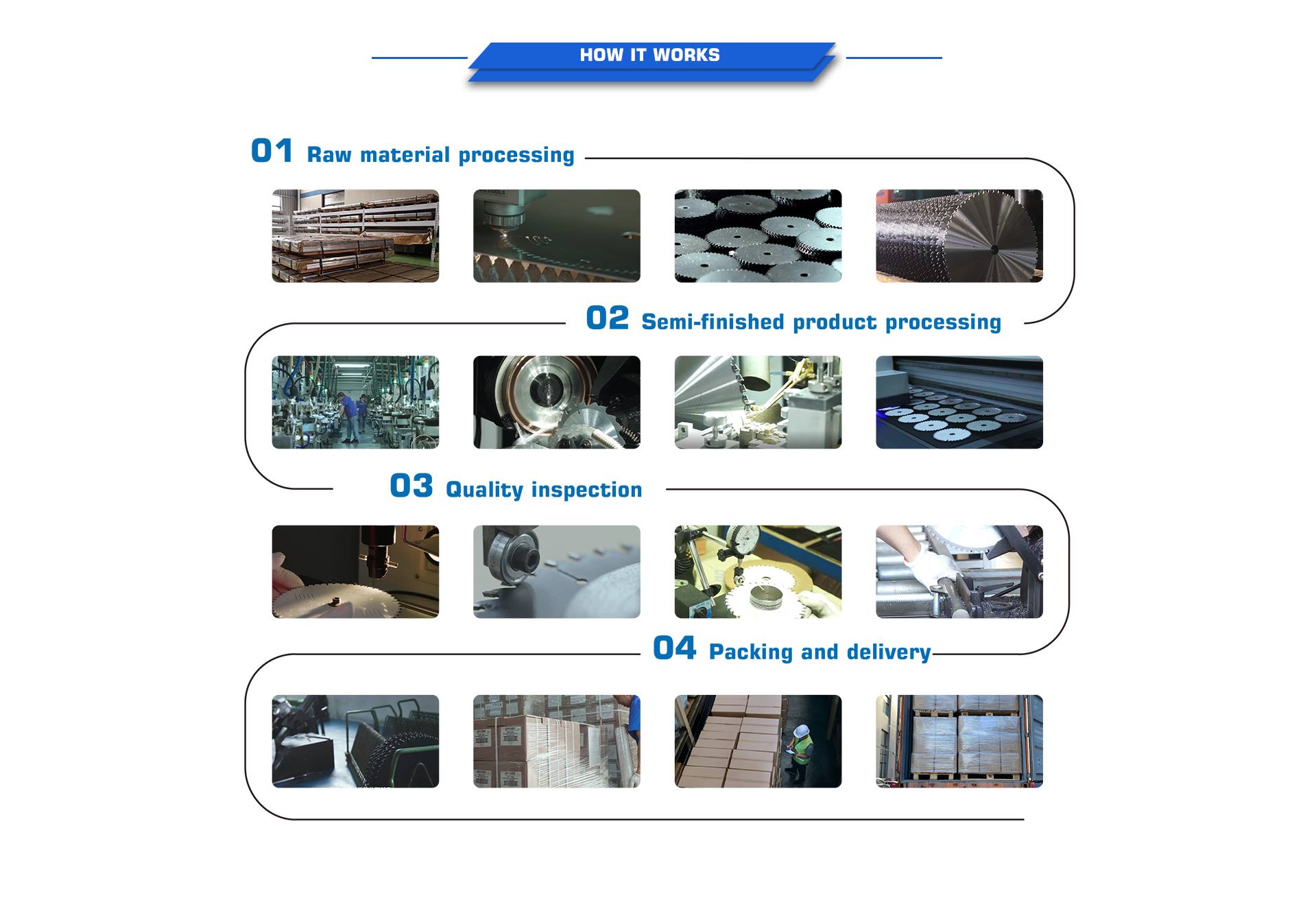

The Process of Customizing Hardware Parts in Taizhou

The customization process of hardware parts in Taizhou typically involves several steps, starting with design and engineering. Here's a breakdown of each stage:

1. Design and Engineering:

To create custom hardware parts, the first step is to develop a detailed design concept. This involves determining the purpose of the hardware part, selecting the appropriate materials, and designing the overall structure. Engineers may use computer-aided design (CAD) software to create accurate 3D models and simulations of the part before moving on to prototyping.

2. prototyping:

Once the design is finalized, the next step is prototyping. This involves creating a physical prototype of the hardware part using a variety of techniques such as CNC (computer numerical control) machining, laser cutting, or water jet cutting. The prototype helps to test the functionality, durability, and aesthetics of the part before mass production begins.

3. Mass Production:

After successful prototyping, the hardware part can be manufactured in large quantities using advanced manufacturing techniques. Taizhou has a well-established network of factories and workshops that specialize in producing metal parts using state-of-the-art equipment. The production process usually includes material selection, processing, assembly, and quality control. It's important to work with a reliable manufacturer that adheres to international standards for quality and safety.

Common Types of Materials Used for Hardware Parts in Taizhou

Taizhou offers a wide range of materials for custom hardware parts, depending on the application's requirements. Here are some common types commonly used in the region:

1. Stainless Steel: High-temperature resistance, excellent corrosion resistance, and strength make stainless steel an ideal choice for applications in food processing, healthcare, and marine environments. Common grades include 304L and 316L.

2. Aluminum: Lightweight, durable, and easy to work with, aluminum is a popular choice for applications in aviation, automotive, and consumer electronics. Common alloys include 6061T6 and 6063T6.

3. Titanium: Strong, lightweight, and resistant to corrosion, titanium is widely used in aerospace, medical, and sports equipment industries. However, it's relatively expensive compared to other metals.

4. Steel: Strong and versatile, steel is a cost-effective choice for many applications. Common grades include ASTM A572 and AISI 1018.

Popular Applications of Customized Hardware Parts in Taizhou

Taizhou's metalworking industry offers a wide range of custom hardware solutions suitable for various industries:

1. Automotive Industry: Custom metal parts for car engines, transmission systems, suspension components, and body panels are produced using advanced manufacturing techniques like CNC machining and laser cutting.

2. Medical Industry: Precision hardware parts for surgical instruments, implantable devices, and prosthetics are manufactured using stainless steel or titanium to ensure cleanliness and biocompatibility.

3. Aerospace Industry: High-strength metal parts for aircraft frames, brackets, wings, and fuselage are produced using aluminum alloys to reduce weight while maintaining durability and strength.

4. Industrial Automation: Customized metal parts for robotics, machinery automation

Articles related to the knowledge points of this article:

Title: Custom Precision Metallic Pads in Guangzhou: The Ultimate Guide

Custom Furniture Hardware: A Comprehensive Guide

Title: Customize Metal Panel Stamping in Nanchang: Your One-Stop Solution for Industrial Hardware

Custom Metal Plate Manufacturers