Custom CNC Precision Metalworking in Huaian: A Comprehensive Guide

Huaian is a city in China that offers custom CNC precision metalworking services. This type of machining involves the use of computer-controlled tools to create intricate designs on metal products. Huaian has become a hub for precision metalworking due to its skilled workforce and advanced technology.CNC machines can create precise cuts and shapes on metal parts with high accuracy and efficiency. They are commonly used in industries such as automotive, aerospace, and medical device manufacturing. However, CNC machining requires specialized knowledge and expertise to operate effectively.To ensure quality workmanship and customer satisfaction, it is important to work with a reputable CNC precision metalworking shop in Huaian. These shops have experience in producing a wide range of metal products, from small prototypes to large-scale production runs.Some key factors to consider when selecting a CNC precision metalworking shop in Huaian include their machine capabilities, production capacity, quality control measures, and pricing. It is recommended to request samples of previous work and to consult with industry experts for guidance before making a decision.In summary, if you are looking for custom CNC precision metalworking services in Huaian, be sure to research and choose a reputable shop that can meet your specific needs and requirements. With the right supplier, you can achieve high-quality results and streamline your production process.

In an increasingly competitive market, precision metalworking has become a vital component for various industries. Among them, CNC (Computer Numerical Control) machining has emerged as a popular and efficient alternative to traditional manual machining. In this article, we will explore the concept of custom CNC precision metalworking in Huai'an, highlighting its key features, benefits, and applications.

CNC machining is a process that uses computer-controlled machines to perform various cutting, drilling, grinding, and shaping operations on metal materials. It offers several advantages over traditional manufacturing techniques, including increased accuracy, speed, flexibility, and consistency. By using computer-aided design (CAD) software, engineers can create detailed prototypes and production parts with exceptional precision and quality.

One of the primary advantages of CNC machining is its ability to produce large volumes of high-quality parts efficiently and cost-effectively. This makes it ideal for mass production applications in industries such as automotive, aerospace, consumer electronics, and medical equipment. Additionally, CNC machines can work with a wide range of metal types, including steel, aluminum, titanium, and alloys, making them highly versatile tools for various engineering challenges.

Huai'an, located in eastern China, is known for its thriving precision metalworking industry. The city has a long history of producing high-quality mechanical components and products, dating back to the early 20th century. Today, Huai'an is home to numerous CNC machining factories and suppliers that offer a wide range of services, including design, prototyping, and production.

To cater to the growing demand for custom CNC precision metalworking in Huai'an, several factors contribute to the city's success in this field. First and foremost is the skilled workforce. Huai'an boasts a large pool of experienced engineers, technicians, and operators who are well-versed in the latest CNC technologies and practices. This talent allows manufacturers in the city to provide customized solutions tailored to their clients' specific needs and requirements.

Another critical factor is the city's robust infrastructure, including modern facilities, transportation links, and access to raw materials. These factors help ensure that manufacturers can operate efficiently and deliver high-quality products on time. Furthermore, Huai'an's strategic location near major shipping ports provides easy access to global markets, further boosting its competitiveness in the international arena.

Custom CNC precision metalworking in Huai'an typically involves several stages, from initial design and consultation to final product delivery. Here's a general overview of these stages:

1. Design and Consultation: The client provides detailed specifications and requirements for the custom part or product they need produced. The manufacturer's design team uses CAD software to create detailed drawings and simulations of the part or product, taking into account factors such as material selection, size constraints, performance requirements, and cost-effectiveness. During this phase, the manufacturer also discusses any technical challenges or limitations associated with the project.

2. prototyping and testing: Based on the client's feedback and design specifications, the manufacturer creates a prototype of the part or product. This prototype undergoes rigorous testing to verify its functionality, reliability, and compliance with safety standards. Any necessary modifications are made before moving on to mass production.

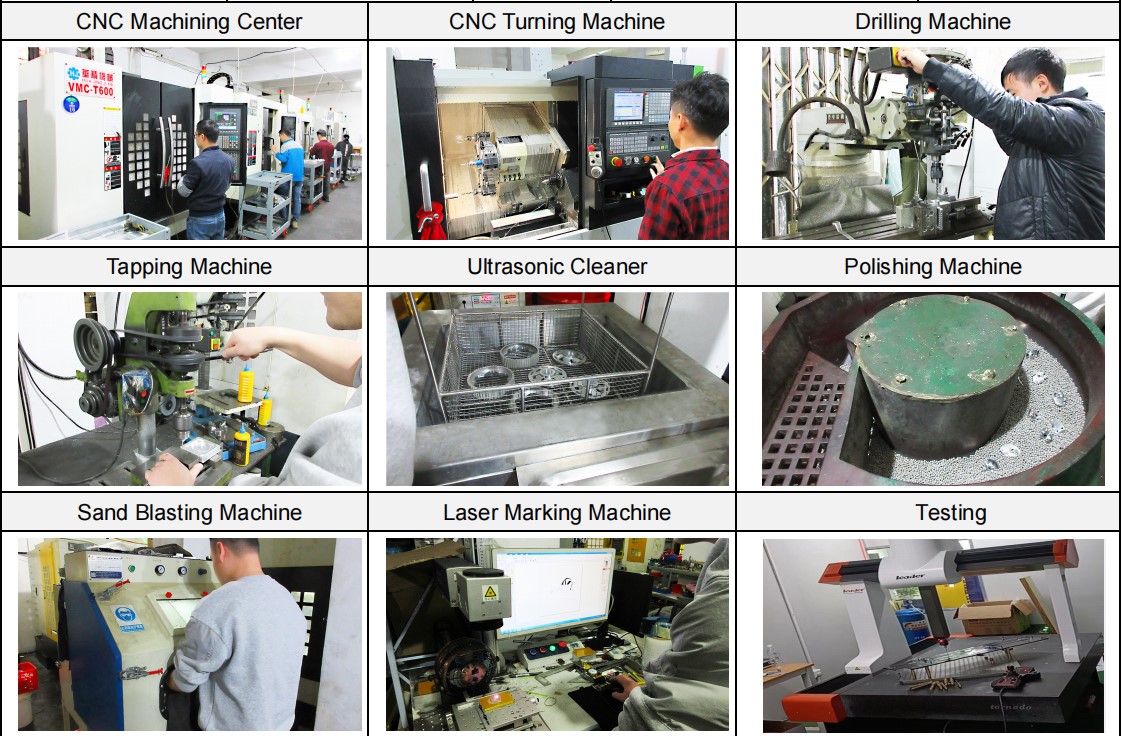

3. Mass Production: Once satisfied with the prototype, the manufacturer begins mass production of the part or product using their CNC machinery and trusted suppliers for raw materials. The manufacturing process involves various stages such as material handling, cutting, grinding, assembly, painting/coating, and quality control. Each stage is carefully monitored and controlled to ensure consistent quality standards are met.

4. Quality Inspection and Delivery: After completing mass production, the manufacturer performs thorough quality inspections to identify any defects or issues with the part or product. Once approved by the client

Articles related to the knowledge points of this article:

Custom Function Hardware for an Entire House: Pictures and More

Title: Innovative Solutions from Ningxia Hardware Processing Customized Manufacturers

Hardware Sample Display Box customization: A Comprehensive Guide