Custom Metal Stamping and Extrusion Parts in Xianning, Hubei Province

Xianning, located in the central part of Hubei Province, is known for its rich metal stamping and extrusion industry. With a long history of over 30 years, Xianning has developed into one of the largest production bases for precision metal stamping parts in China. The city boasts advanced equipment and technology, experienced technicians, and high-quality raw materials. The products produced by Xianning companies include auto parts, medical equipment, electronic devices, and household appliances. The advantages of custom metal stamping and extrusion parts in Xianning lie in their excellent quality, reasonable price, and fast delivery time. These products are widely used in various industries and have won praise from customers around the world. As the demand for precision metal components continues to grow, the metal stamping and extrusion industry in Xianning is expected to continue to develop and expand.

Introduction to Xianning, Hubei Province

Xianning, located in the central part of China, is a city with a long history and rich cultural heritage. It is known as the "City of Fish and Rice" and is home to numerous food delicacies. In recent years, Xianning has become a hub for manufacturing industries, particularly in the fields of metal stamping and extrusion parts. This article will provide an overview of custom metal stamping and extrusion parts in Xianning, Hubei Province, including their production process, materials used, and applications.

Production Process of Metal Stamping and Extrusion Parts

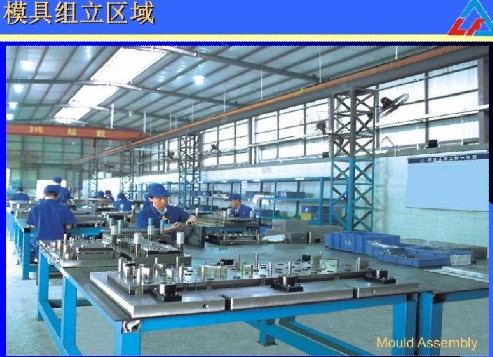

The production process of metal stamping and extrusion parts typically consists of several steps, including design, prototyping, raw material procurement, processing, and assembly. Here's a detailed look at each step:

1、Design: The first step in producing custom metal stamping and extrusion parts is designing the product according to customer requirements. This involves creating 2D and 3D drawings of the final product, determining the material type, size, and shape of the components, and specifying any special features or requirements.

2、Prototyping: Once the design is finalized, a prototype is created using either computer-aided design (CAD) software or rapid prototyping technology. This allows the customer to evaluate the product's functionality and appearance before committing to mass production.

3、Raw Material Procurement: Based on the selected material type, the factory sources high-quality raw materials from reliable suppliers. Common metals used for metal stamping and extrusion parts include aluminum, steel, stainless steel, and plastics.

4、Processing: The next step involves cutting, bending, spinning, drilling, and other forming operations to convert the raw materials into the final product. This may involve using specialized machinery such as press brakes, lathes, cnc machines, and welding equipment.

5、Assembly: After forming the components into their final shape, they are assembled into complete products according to the specified requirements. This may involve adding screws, nuts, bolts, or other hardware to ensure proper function and safety.

Materials Used for Custom Metal Stamping and Extrusion Parts

The choice of material depends on several factors such as cost, performance, durability, and environmental impact. Popular materials for metal stamping and extrusion parts include:

1、Aluminum: A lightweight and corrosion-resistant material commonly used for aerospace, automotive, and consumer electronics applications. Its strength-to-weight ratio makes it an attractive option for high-performance products.

2、Steel: A strong and durable material suitable for various industrial applications such as construction, machinery, and transportation. It comes in different grades based on its composition and surface finish to meet specific performance requirements.

3、Stainless Steel: A heat-resistant and corrosion-resistant material ideal for food processing, medical devices, and water treatment systems. It features excellent sanitation properties due to its non-porous surface.

4、Plastics: A versatile material used in various forms such as sheets, rods, pipes, and injection molded parts. It offers excellent mechanical properties and low weight compared to some other materials but may be less durable in extreme temperatures or harsh environments.

Applications of Custom Metal Stamping and Extrusion Parts

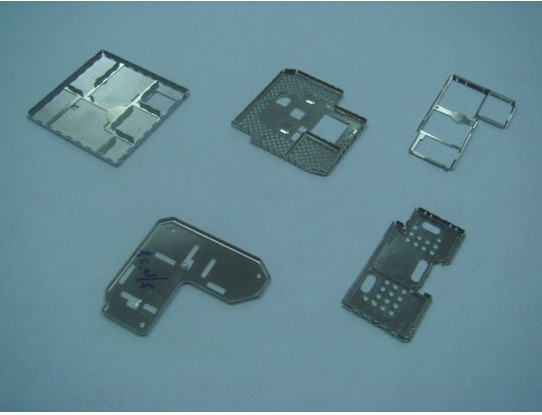

Custom metal stamping and extrusion parts have numerous applications across various industries due to their flexibility, precision, and affordability. Some popular examples include:

1、Automotive industry: Metal stamping and extrusion parts are essential components in automobile bodies, engines, transmission systems, and electrical panels. They play a crucial role in ensuring the safety and reliability of vehicles.

2、Electronics industry: These parts are widely used in consumer electronics such as smartphones, laptops, televisions, and home appliances. They help protect sensitive components from damage and enhance device performance.

3、Construction industry: Metal stamping and extrusion parts are used in building structures such as bridges, buildings, and infrastructure projects. They provide support, reinforcement, and stability to ensure structural integrity.

4、Medical industry: These parts are used in medical devices such as prosthetics, implants

Articles related to the knowledge points of this article:

Title: Superior Home Design: Custom Hardware for Your Dream Home

Title: Customizing Hardware for Reliable and Durable Baggage in Xiamen

Custom Tailored Jackets for the Elite: A Look into the World of Hardware and Clothing

Title: Customized Hardware Handles Manufacturer in Hubei: An Expert Guide