Crafting Custom Hardware Solutions: The Art of Quality Metal Components

Crafting Custom Hardware Solutions: The Art of Quality Metal ComponentsCustom hardware solutions require a unique approach that involves precision, expertise and attention to detail. The art of creating high-quality metal components lies in the ability to understand the needs of the client and deliver products that meet their specific requirements. This requires a deep understanding of the material properties, design principles and manufacturing processes involved.One key aspect of crafting custom hardware solutions is to work closely with clients to define their needs and expectations. This involves listening carefully, asking questions and collaborating with them throughout the design process. By understanding the client's vision and objectives, designers can create products that not only meet but exceed their expectations.Another important aspect of quality metal components is ensuring consistency in manufacturing. Precision manufacturing techniques such as CNC (computer numerical control) machining and stamping ensure that each component is made to exact specifications, providing a consistent product quality across multiple units.In addition to precision and consistency, custom hardware solutions must also be aesthetically pleasing. Designers must consider factors such as material choice, color and finish to create products that are both functional and visually appealing.Overall, crafting custom hardware solutions is an art that combines technical expertise with creative vision. By working closely with clients, utilizing precision manufacturing techniques and paying attention to aesthetics, designers can deliver high-quality metal components that meet the diverse needs of modern industries.

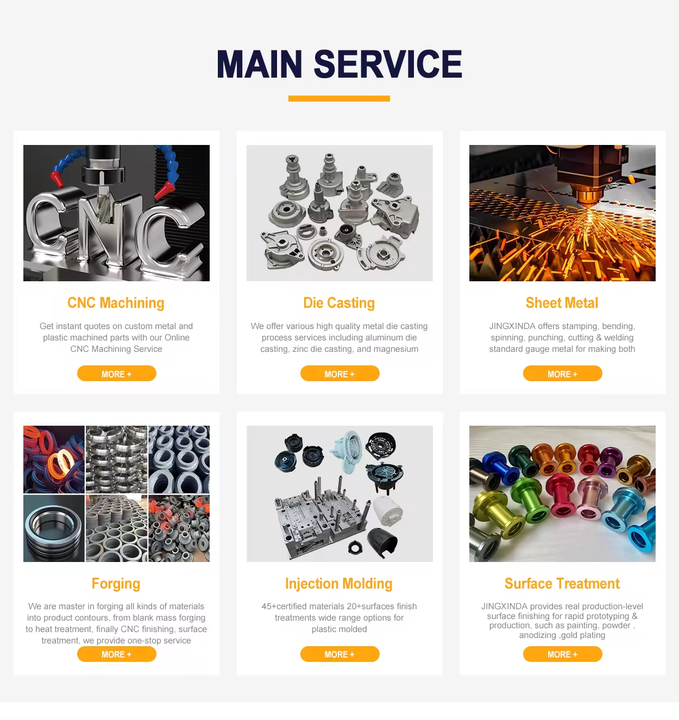

In the world of industrial manufacturing, precision and efficiency are paramount. This is especially true in the realm of hardware components, where even the slightest deviation from specifications can have significant consequences. As such, the demand for high-quality metal components that can be customized to meet specific needs has grown steadily in recent years. This has given rise to a specialized field of craftsmanship known as "quality metal component customization." At its core, this field focuses on creating custom metal parts that not only meet but exceed industry standards for durability, reliability, and performance.

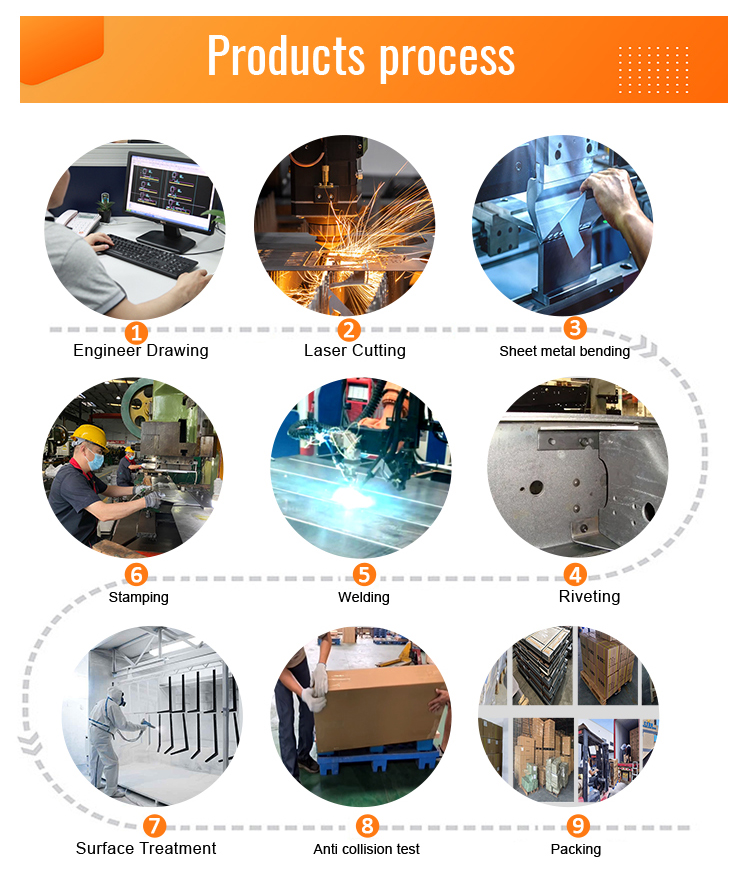

The process of creating custom metal components begins with careful planning and design. Skilled engineers and designers use state-of-the-art software to map out every detail of the part, from its dimensions and shape to its materials and finish. They also consider factors such as load-bearing capacity, vibration resistance, and environmental conditions when designing the part. Once the design is complete, the next step is to select the appropriate raw materials for production. This often involves a delicate balancing act between cost, quality, and availability, as some materials may be more expensive or harder to source than others.

After the raw materials have been selected, the actual manufacturing process begins. This typically involves several steps, including cutting, bending, drilling, and welding. Each of these steps requires precise measurement and skilled execution in order to produce components that meet the required specifications. In addition, many custom metal components require additional finishing touches, such as painting or plating, to ensure maximum durability and resistance to corrosion.

Despite the many complexities involved in creating custom metal components, the benefits are clear. By working closely with customers to understand their unique needs and requirements, manufacturers can create products that are tailored to their specific use case. This not only leads to higher levels of satisfaction for end users but can also help manufacturers differentiate themselves in an increasingly competitive market. Moreover, by investing in the latest technologies and best practices, quality metal component manufacturers can continuously improve their processes and stay ahead of industry trends.

At the heart of it all is a commitment to quality. From the initial design phase to the final inspection and delivery, every step of the process must adhere to strict standards of excellence. This requires not only technical expertise but also a deep understanding of customer needs and a willingness to go above and beyond to ensure satisfaction. It is this dedication to quality that sets apart quality metal component manufacturers from their competitors and helps them build long-term relationships with customers.

In conclusion, the art of crafting custom metal components is a complex and nuanced one that demands the highest levels of precision, craftsmanship, and dedication. Yet for manufacturers who are able to master this craft, the rewards can be substantial. By focusing on quality over quantity and tailoring their products to meet the unique needs of each customer, these manufacturers can establish themselves as leaders in their field and drive sustainable growth for their businesses. So whether you're looking for a simple metal bracket or a sophisticated piece of machinery, know that you can count on the experts at your local quality metal component manufacturer to deliver nothing less than excellence.

Articles related to the knowledge points of this article:

Top 10 Brands of Door and Window Hardware Fittings

Stationery and Hardware Accessories

The application of ERP system in hardware accessories industry

Title: Attention Points When Manufacturing Hardware Accessories in Xuzhou

Title: Shenzhens Informationization of Hardware Parts Planning

Title: The Cost of High-Quality Hardware Accessories Processing in Nanjing