Customized Metallurgical Cleaning and Drying Equipment: A Comprehensive Guide

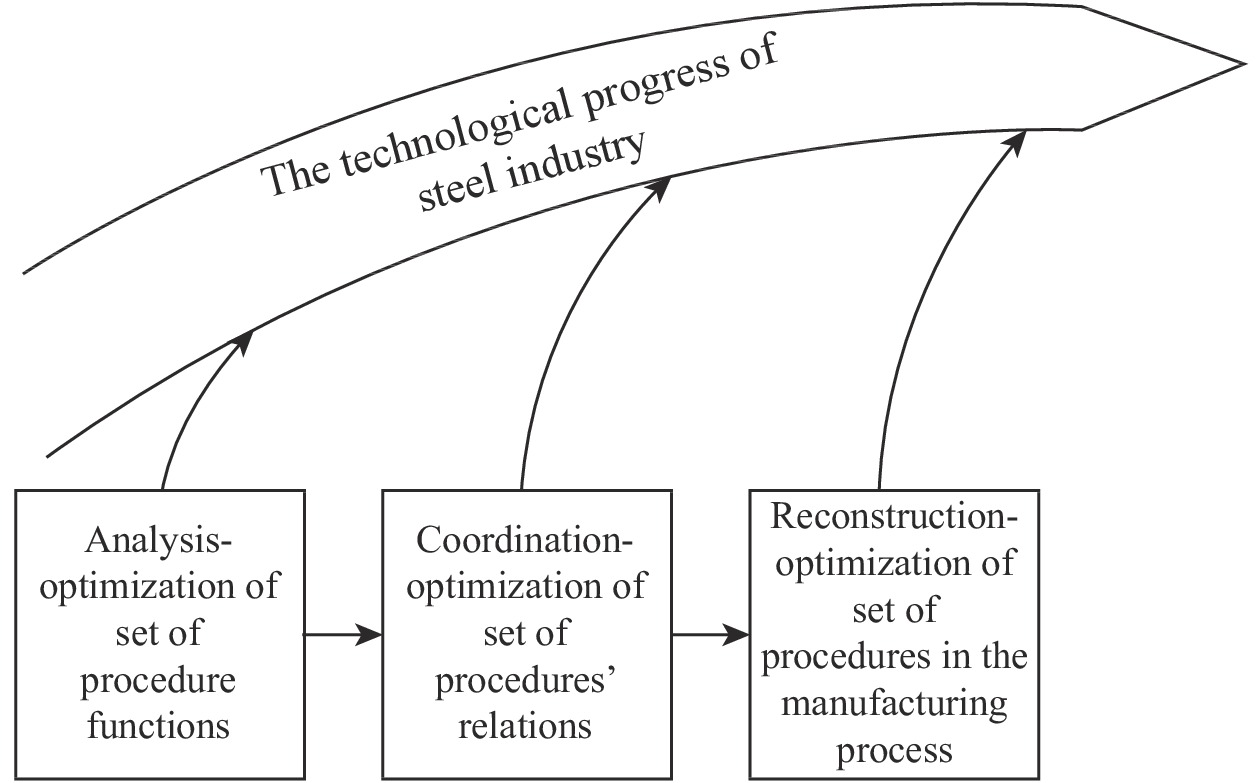

Customized Metallurgical Cleaning and Drying Equipment is a comprehensive guide that provides detailed information on the design, construction, and operation of customized cleaning and drying equipment for the metallurgical industry. The guide covers various aspects of the equipment, including the selection of appropriate materials, design, construction, and testing. It also discusses the importance of proper maintenance and safety measures to ensure the efficient and safe operation of the equipment. The guide provides practical solutions for metallurgical companies looking to optimize their cleaning and drying processes, improve product quality, and reduce production costs. The comprehensive guide offers valuable insights into the latest trends and best practices in the metallurgical industry, making it a must-read for manufacturers and engineers working in the field. With its clear and concise writing style, this guide is easy to understand and provides a comprehensive overview of customized metallurgical cleaning and drying equipment.

Introduction:

In the industrial sector, metallurgy plays a crucial role in the production of various products. The process involves various stages, such as smelting, casting, refining, and finishing. Each stage requires precise equipment to ensure efficiency and quality. One such equipment is the metallurgical cleaning and drying machine, which helps to remove impurities, contamination, and moisture from metals during the processing. In this article, we will discuss the importance of customization in metallurgical cleaning and drying equipment and explore some key factors to consider when selecting a suitable device.

The Importance of Metallurgical Cleaning and Drying Equipment:

Metallurgical cleaning and drying equipment is essential for maintaining the integrity and quality of metals throughout the manufacturing process. It helps to:

1、Remove impurities and contaminants: Irregularities in the metal surface, such as scratches, dents, or cracks, can affect its mechanical properties and lead to defects in the final product. Metallurgical cleaning equipment removes these imperfections, ensuring that the metal retains its strength and durability.

2、Reduce moisture content: Moisture can adversely affect the performance of metals, causing rusting, corrosion, or other forms of damage. Metallurgical drying equipment eliminates excess moisture, preserving the metal's properties and extending its lifespan.

3、Improve efficiency: By removing impurities and reducing moisture, metallurgical cleaning and drying equipment helps to streamline the manufacturing process, saving time and resources while also improving overall productivity.

Customization Options:

When it comes to choosing a metallurgical cleaning and drying equipment, customization is essential to meet specific production requirements. There are several factors to consider when selecting a device that meets your needs:

1、Material compatibility: The first step in customization is to determine the type of metal you will be working with. Different metals require different cleaning and drying techniques, so it's crucial to choose equipment compatible with your material of choice. Some common materials used in metallurgy include aluminum, steel, titanium, and nickel.

2、Surface area: The size of the surface area to be cleaned and dried determines the size and configuration of the cleaning and drying equipment. For example, if you need to clean a large area of metal quickly, you may opt for a larger-scale machine with multiple scrubbing brushes or air flow systems. Conversely, if you need to clean delicate surfaces like surgical instruments or electronic components, you may require specialized equipment with smaller brushes or gentle cleaning methods.

3、Deterioration control parameters: Metallurgical cleaning and drying processes can cause wear and tear on equipment over time. To extend the life of your device and maintain optimal performance, consider incorporating features such as temperature control, pressure regulation, and automatic shut-off systems that prevent damage due to excessive stress or wear.

4、Energy efficiency: Energy consumption is a significant concern in today's sustainable manufacturing practices. Look for metallurgical cleaning and drying equipment that offers high energy efficiency ratings or implements eco-friendly technologies like heat recovery systems or renewable energy sources like solar panels or wind turbines.

5、Custom design: Finally, consider having your metallurgical cleaning and drying equipment designed according to your specific requirements. This customization may include adding special attachments or sensors for monitoring the cleaning process or integrating software controls for easier operation and maintenance. Working with a reputable manufacturer who offers customized solutions can help you achieve the ideal balance between performance, cost-effectiveness, and flexibility.

Conclusion:

In conclusion, metallurgical cleaning and drying equipment plays a crucial role in maintaining the quality and integrity of metals used in various industrial applications. Choosing a suitable device that meets your specific production requirements is essential for achieving optimal results while minimizing costs and maximizing efficiency. By considering factors such as material compatibility, surface area, deterioration control parameters, energy efficiency, and custom design options, you can select a metallurgical cleaning and drying equipment that best suits your needs.

Articles related to the knowledge points of this article:

Title: Custom Wardrobe Hardware Hangao: A Guide to Choosing the Best Hardware for Your Wardrobe

Customized Hardware Stretching Manufacturers

Title: Revolutionizing Home Customization: The Premier Hub for Customized Hardware in China

Title: Custom Metalworking Factory in Foshan: A Comprehensive Guide