Zhejiang Hardware Manufacturers Production of Aluminium Wire Cables

The production of aluminum wire cables in the Zhejiang hardware industry has been a key component of their economic growth. The state-of-the-art equipment used for manufacturing these wires allows for high precision and consistency in production, ensuring that they meet the highest standards of quality. The demand for these wires has grown significantly due to their versatility and durability, making them ideal for a wide range of applications including construction, electrical wiring, and automotive parts manufacturing. With the ongoing development of technology and innovation within the industry, it is expected that the production of aluminum wire cables in Zhejiang will continue to grow and expand, providing numerous employment opportunities for the local population while contributing to the overall economic development of the region.

Zhejiang Province, known for its thriving hardware industry, has been at the forefront of manufacturing excellence in China. Among the various products produced by Zhejiang hardware manufacturers is the铝线电缆, a versatile and essential component of modern electrical infrastructure. This article delves into the production process, materials used, and the importance of quality control in the manufacture of aluminium wire cables in Zhejiang.

The aluminum wire cable is an integral part of the electrical transmission and distribution system. It is made from high-strength aluminum wires that are tightly twisted together to form a solid conductor. The cable is then protected by an outer sheath of plastic or another material depending on the specific application.

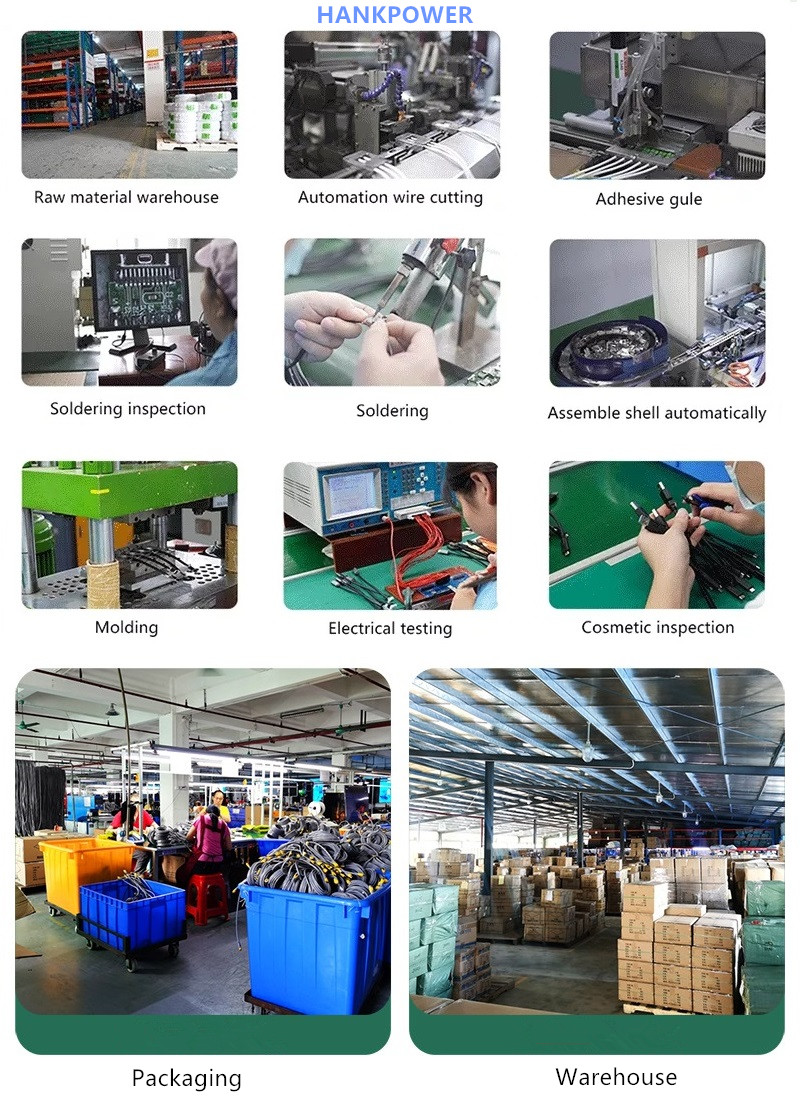

In Zhejiang, several leading hardware manufacturers specialize in the production of aluminium wire cables. These companies employ advanced machinery and technology to ensure consistent quality and efficiency in the manufacturing process. The production line typically starts with raw materials, including high-strength aluminum wires, plastic compounds, and other additives.

The aluminum wires are carefully selected based on their strength, purity, and other properties that are necessary for the cable's performance. The wires are then subjected to various processing stages, including cleaning, stretching, and twisting, to form the core of the cable. The twisting process involves rotating the wire around a mandrel at high speeds to create a tight bond between the wires. This step is crucial as it determines the cable's strength and flexibility.

After the core is formed, it is surrounded by a protective layer of plastic or another material. This layer helps to prevent damage from environmental factors, such as UV rays, moisture, and chemicals. The cable is then subjected to rigorous quality control tests to ensure that it meets specific standards for strength, resistance to voltage surges, and other parameters.

The final step in the production process is packaging and shipping. The aluminium wire cables are packaged in protective boxes or bags and labeled according to their specific use and characteristics. The cables are then shipped to customers across the country, where they are installed in various electrical systems, including power plants, substations, and homes.

Quality control is a critical aspect of the aluminium wire cable manufacturing process in Zhejiang. The manufacturers employ several measures to ensure that the finished product meets strict standards. These include regular inspections during the production process to identify any defects or issues with the cables. In addition, after production, each cable is subject to comprehensive testing before being shipped to customers. This testing includes checks for strength, resistance to voltage surges, and other parameters specified by international standards.

The importance of quality control in the manufacture of aluminium wire cables cannot be overstated. Poorly manufactured cables can pose serious safety hazards, particularly in large-scale power generation and distribution systems. On the other hand, well-made cables can ensure reliable and efficient electrical transmission and distribution, contributing to economic growth and social development. By investing in quality control measures, Zhejiang hardware manufacturers are not only ensuring the safety and reliability of their products but also contributing to the overall competitiveness of the province's hardware industry.

In conclusion, Zhejiang hardware manufacturers have established a reputation for producing high-quality aluminium wire cables that meet international standards. Through their advanced technology, rigorous quality control processes, and commitment to excellence, these manufacturers play a vital role in ensuring the safe and efficient operation of modern electrical systems. As the demand for electrical infrastructure continues to grow worldwide, it is clear that the future of Zhejiang's hardware industry lies in its ability to innovate and adapt to changing market demands while maintaining the highest standards of quality and safety.

Articles related to the knowledge points of this article:

Local Hardware Manufacturers in Yangzhou

Title: Exploring the Exemplary Hardware Manufacturing House of Xuzhou: A Journey to its Address

Title: Unlocking the Potential: Hebei Yueqin Metalworking Factory