The Comprehensive Process of Hardware Wholesale

Hardware wholesale is a complex process that involves several stages. The first step is to determine the type and quality of hardware required for the project. This includes identifying the specific hardware components such as screws, bolts, nails, and hinges that are needed. Once this has been determined, it is important to source these components from reputable suppliers who can provide high-quality products at competitive prices.After sourcing the hardware components, the next step is to assemble them into complete assemblies. This requires careful planning and coordination to ensure that all components are compatible and fit properly. It may also involve adding additional features or customizations to the hardware to meet specific project requirements.Once the hardware assemblies have been completed, they must be inspected thoroughly to ensure that they meet quality standards and are free of defects. Any defective or substandard hardware must be removed and replaced with new components.Finally, the hardware must be packaged and labeled appropriately for distribution to retailers or end users. This involves ensuring that the packaging is sturdy enough to protect the hardware during transportation while also providing clear labeling that indicates the contents of the package.Overall, hardware wholesale is a multifaceted process that requires attention to detail and careful planning to ensure that each component meets quality standards and is delivered on time. By following a comprehensive process, hardware wholesalers can provide their customers with high-quality products at competitive prices.

Hardware wholesale is a complex and multi-step process that involves various stages to ensure the smooth distribution of raw materials, manufacturing, and delivery of finished products. This article will provide an in-depth overview of the hardware wholesale process, from sourcing raw materials to delivering finished products to customers.

1. Sourcing Raw Materials

Sourcing raw materials is a crucial step in the hardware wholesale process. The quality and reliability of raw materials directly impact the final product's performance, durability, and cost-effectiveness. To ensure high-quality raw materials, suppliers must have robust sourcing networks, rigorous quality control procedures, and reliable logistics support.

a. Establishing Relationships with Suppliers

To source raw materials efficiently, hardware wholesalers work closely with suppliers, building long-term relationships based on trust, transparency, and mutual respect. These relationships often involve negotiating prices, establishing payment terms, and sharing knowledge about market trends, customer preferences, and industry best practices.

b. Conducting Market Research

Before sourcing raw materials, hardware wholesalers must conduct thorough market research to identify the most popular types of materials, their availability, pricing, and potential demand. This research helps wholesalers make informed decisions about which materials to source, how much to order, and when to place orders.

c. Quality Control Procedures

Once raw materials are sourced, hardware wholesalers must implement rigorous quality control procedures to ensure that the materials meet specific standards and requirements. Quality control measures may include testing for chemical composition, physical properties, and surface finish; inspecting the materials for defects or inconsistencies; and verifying the supplier's certifications and qualifications.

d. Logistics Support

Logistics play a critical role in ensuring the timely delivery of raw materials to hardware wholesalers. Suppliers must have efficient transportation systems, storage facilities, and packaging solutions to manage the inventory and minimize waste. Hardware wholesalers also need to coordinate with logistics providers to plan shipments and track the progress of deliveries.

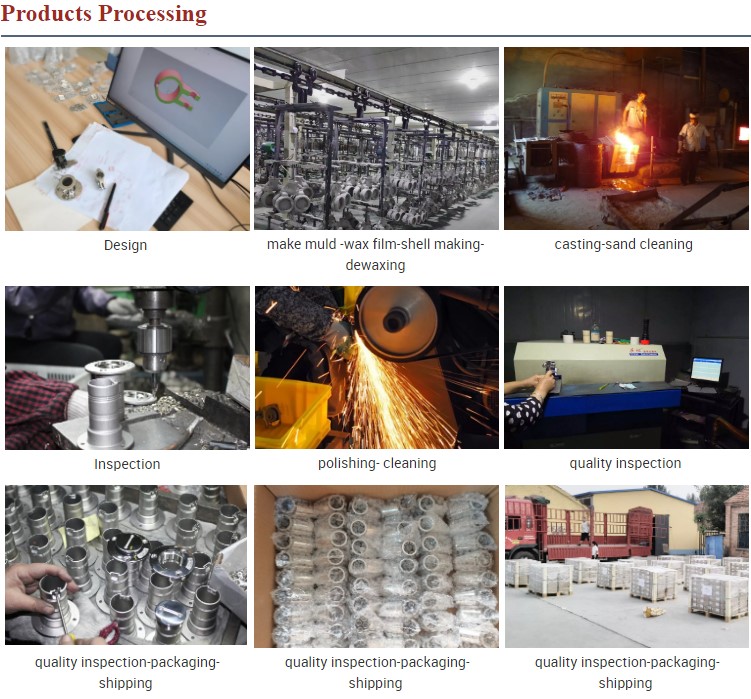

1. Manufacturing

After receiving raw materials, hardware wholesalers move into the manufacturing stage, where they transform raw materials into finished products ready for distribution. The manufacturing process may involve several steps depending on the type of product being produced and the complexity of its components.

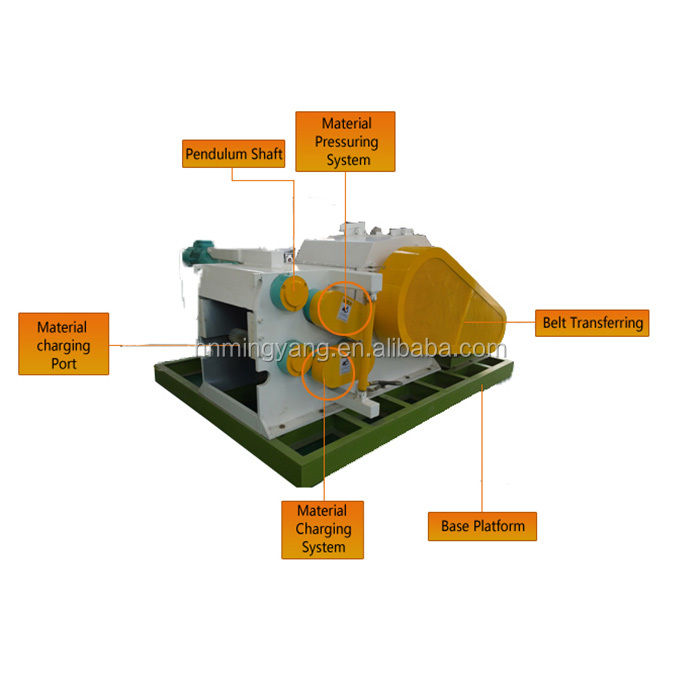

a. Designing Products

Product design is an essential aspect of hardware manufacturing. Designers work closely with customers to understand their needs, preferences, and budget constraints to create functional and attractive products that meet market demands. They use computer-aided design (CAD) software to generate detailed drawings and specifications for each product.

b. Sourcing Components

Hardware products often require multiple components that need to be sourced from different suppliers. Wholesalers must collaborate with component suppliers to ensure that the required components are available at competitive prices and meet the product's specifications. They may negotiate bulk discounts, arrange for expedited shipping, or establish long-term relationships with component manufacturers.

c. Fabricating Products

Once all components are sourced, hardware wholesalers start fabricating products using various manufacturing techniques such as welding, drilling, milling, or cutting. Fabrication processes vary depending on the product type and complexity but generally involve shaping and joining metal components together to create a finished product.

d. Quality Control in Manufacturing Processes

Quality control measures continue during the manufacturing process to ensure that each product meets strict standards and specifications. Manufacturers perform regular inspections to check for defects or inconsistencies in the products' dimensions, surface finish, and overall functionality. They may also use statistical process control (SPC) techniques to monitor production processes and detect any patterns or anomalies that could indicate quality issues.

1. Packaging and Shipping

The final stage of the hardware wholesale process is packaging and shipping completed products to customers worldwide. Effective packaging ensures that the products remain safe during transit while also enhancing their aesthetic appeal and brand identity. Shipping methods depend on factors such as product size, weight, destination, and customer preference, but common options include air freight, container shipments, or express courier services.

a. Packaging Solutions

Wholesalers must choose appropriate packaging solutions that protect the products during transport while also minimizing waste and environmental impact. Common packaging materials include cardboard boxes, foam peanuts, plastic bags, or wooden crates. Wholesalers may also customize packing materials to enhance brand recognition or showcase unique product features.

b. Shipping Planning

Before shipping completed products, hardware wholesalers must plan the shipping routes, select appropriate carriers, and arrange for necessary documentation such as commercial invoices, customs declarations, or tracking numbers. They may also use software tools to automate shipping processes and optimize costs by selecting the most efficient shipping routes or carrier options.

c. Deliveries and Customer Service

After the products are shipped, hardware wholesalers continue providing excellent customer service by monitoring delivery statuses

Articles related to the knowledge points of this article:

Wholesale Hardware Valve Plate

Title: City of Yangs Hardware Wholesale Market - A Hub of Trade and Innovation

Title: Exploring the Wonders of Zhengzhou Hardware and Daily Commodity Wholesale Market

Fishing Dragon Hardware Wholesale

Title: Exploring the Wonders of Jiangmen Hardware and Electrical Wholesale Market