Customizing Metal Parts Sourcing and Procurement: A Comprehensive Guide

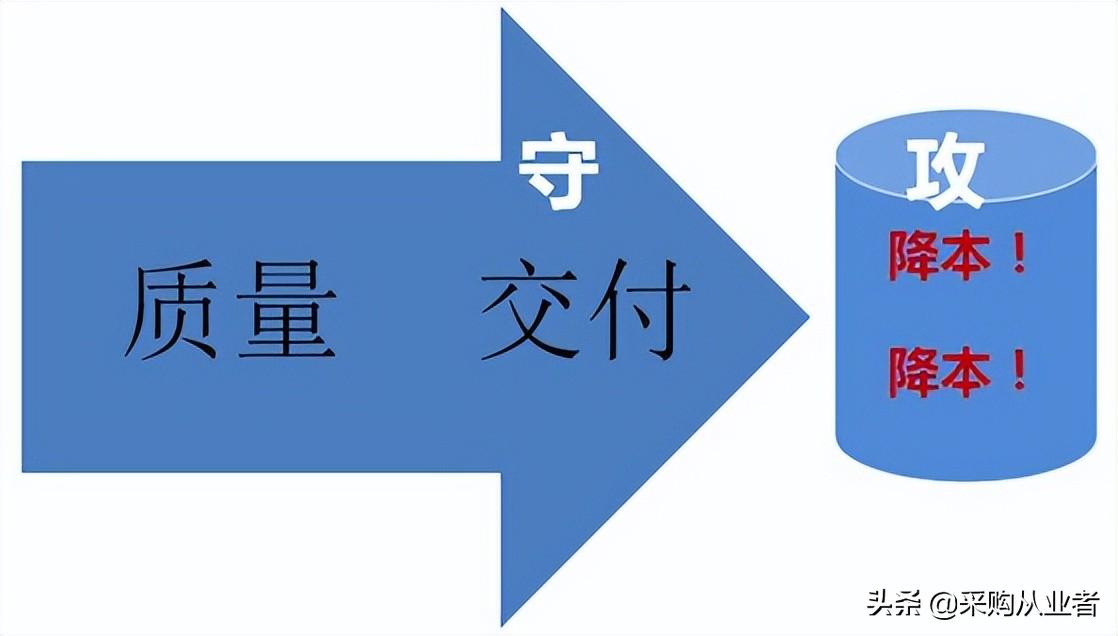

Customizing metal parts sourcing and procurement requires a comprehensive guide to ensure success. The process involves identifying the right suppliers, evaluating their capabilities, and negotiating favorable pricing and delivery terms. It also entails ensuring quality control standards are met throughout the manufacturing process.To start, companies must assess their current sourcing and procurement practices and identify areas for improvement. This may involve conducting market research to identify new suppliers or adjusting existing contracts with current vendors. Companies should also establish specific requirements for their customized metal parts, including material type, finish, and dimensions.Once suppliers have been identified, companies should evaluate their capabilities and assess their ability to meet the specified requirements. This may involve requesting samples of previous work or conducting on-site audits of potential vendors. Companies should also negotiate favorable pricing and delivery terms, including lead times and delivery schedules.During the manufacturing process, companies should implement quality control measures to ensure the customized metal parts meet their specifications. This may include regular inspections by quality control personnel or using advanced testing equipment to verify the quality of finished products.Overall, customizing metal parts sourcing and procurement requires a comprehensive approach that includes identifying suitable suppliers, negotiating favorable terms, implementing quality control measures, and regularly monitoring performance to ensure continued success.

In today's rapidly evolving industrial landscape, metal parts play a crucial role in the functioning of numerous machines and structures. The demand for customized metal components continues to increase, driving the growth of the sourcing and procurement sector. This has created a need for specialized suppliers who can cater to the specific requirements of their clients. In this article, we will explore the key aspects of customizing metal parts sourcing and procurement, including the process, advantages, challenges, and best practices.

The Process of Customizing Metal Parts Sourcing and Procurement

At its core, customizing metal parts sourcing and procurement involves creating a unique product that meets the specific needs and specifications of a client. This process typically includes several stages, each with its own set of considerations.

Client Consultation: The first step is to understand the client's requirements thoroughly. This involves gathering information about the type of metal parts required, their size, shape, material, weight, and other relevant factors. Additionally, it involves discussing any design preferences or aesthetic requirements the client may have.

Finding a Supplier: Once the client's requirements have been established, the next step is to find a suitable supplier. This could involve conducting research online, attending trade shows, or reaching out to existing suppliers. It is important to compare various suppliers based on factors such as quality, price, lead time, and customization capabilities.

Negotiating Contract Terms: After selecting a supplier, the next step is to negotiate contract terms. This involves agreeing on payment terms, delivery schedule, and any other relevant details. It is also an opportunity to clarify any remaining questions or concerns regarding the custom metal part.

Production and Delivery: With the contract terms finalized, the supplier can begin production. During this stage, it is important to maintain open communication with the supplier and monitor progress to ensure that the final product meets the agreed-upon specifications. Upon completion, the supplier will deliver the metal part(s) as agreed.

Advantages of Customizing Metal Parts Sourcing and Procurement

There are several advantages tocustomizing metal parts sourcing and procurement. Some of these include:

Flexibility: Custom metal parts allow for greater flexibility in design and functionality compared to off-the-shelf products. This enables customers to create truly unique products that meet their specific needs.

Quality Control: By working directly with a supplier, customers can have greater control over the quality of the final product. They can ensure that the metal part meets their exact specifications and has been manufactured to their standards.

Cost Savings: Custom metal parts can often be more cost-effective than off-the-shelf products due to their flexibility and reduced waste. Customers can also take advantage of volume discounts when ordering large quantities of customized components.

Challenges Associated with Customizing Metal Parts Sourcing and Procurement

Despite the many benefits of customizing metal parts sourcing and procurement, there are also several challenges that must be addressed. These include:

Long Lead Times: The customization process often requires additional time compared to mass production. Customers must be prepared to wait longer before receiving their finished products.

Limited Availability: Some suppliers may not have the capability to customize certain types of metal parts or may not have the necessary resources to produce large quantities. Customers may need to be flexible in their search for a suitable supplier.

Quality Control: While custom metal parts offer greater control over quality, they also require careful monitoring throughout the production process to ensure that they meet the agreed-upon specifications.

Best Practices for Customizing Metal Parts Sourcing and Procurement

To ensure success in customizing metal parts sourcing and procurement, it is important to follow best practices. These include:

Establish Clear Communication Channels: Regular communication with suppliers is critical to ensuring that everyone is on the same page throughout the process. This includes regular updates on production progress and any issues that arise.

Conduct thorough market research: Conducting thorough market research can help customers identify suitable suppliers and compare their offerings based on factors such as quality, price, and customization capabilities.

Articles related to the knowledge points of this article:

Custom Home Hardware: A Guide to Selecting and Installing Quality Hardware for Your Home

Title: Customized Hardware and Accessories in Fashion Industry: A Comprehensive Guide

Title: Embracing Quality and Customer-centricity: An Insight into Bejings Customized Hardware Stores

Customized Hardware Components by Weiyi - A Premier Provider of Quality and Precision