Plastic and Metal Hardware Components Manufacturers

Plastic and Metal Hardware Components Manufacturers The industry of plastic and metal hardware components has seen significant growth in recent years. With the increasing demand for lightweight, durable, and cost-effective products, these components have become crucial for various applications. Manufacturers have adopted advanced technologies to produce high-quality and precision components that meet the stringent requirements of their customers. From plastic fasteners to metal bearings, these components are essential for the smooth functioning of machines and equipment. The industry is poised for further growth as manufacturers continue to innovate and improve their products to meet the evolving needs of their customers.

Plastic and metal hardware components have become essential components of various industrial and consumer products. These components, which are primarily used for connecting, supporting, and protecting other parts of a product, are crucial for the proper functioning and longevity of a product. In this article, we explore the role of plastic and metal hardware components in product design and manufacturing.

Firstly, plastic hardware components have numerous advantages in product design. They are lightweight and easy to transport, making them ideal for reducing the overall weight of a product. Additionally, plastics are resistant to corrosion, which means they can be used in harsh environments without worrying about deterioration. Another advantage of plastic components is their low cost, which helps to reduce the overall cost of production.

Metal hardware components, on the other hand, have their own unique set of advantages. They are strong and durable, making them suitable for applications that require high levels of structural integrity. Metals are also excellent conductors of heat and electricity, making them ideal for products that involve these elements. Furthermore, metal components can be easily customized to meet specific design requirements, providing manufacturers with more flexibility in product development.

However, it is important to note that the choice of plastic or metal hardware components depends on the specific application and product requirements. In some cases, a combination of both materials may be necessary to achieve the desired balance of cost, performance, and durability.

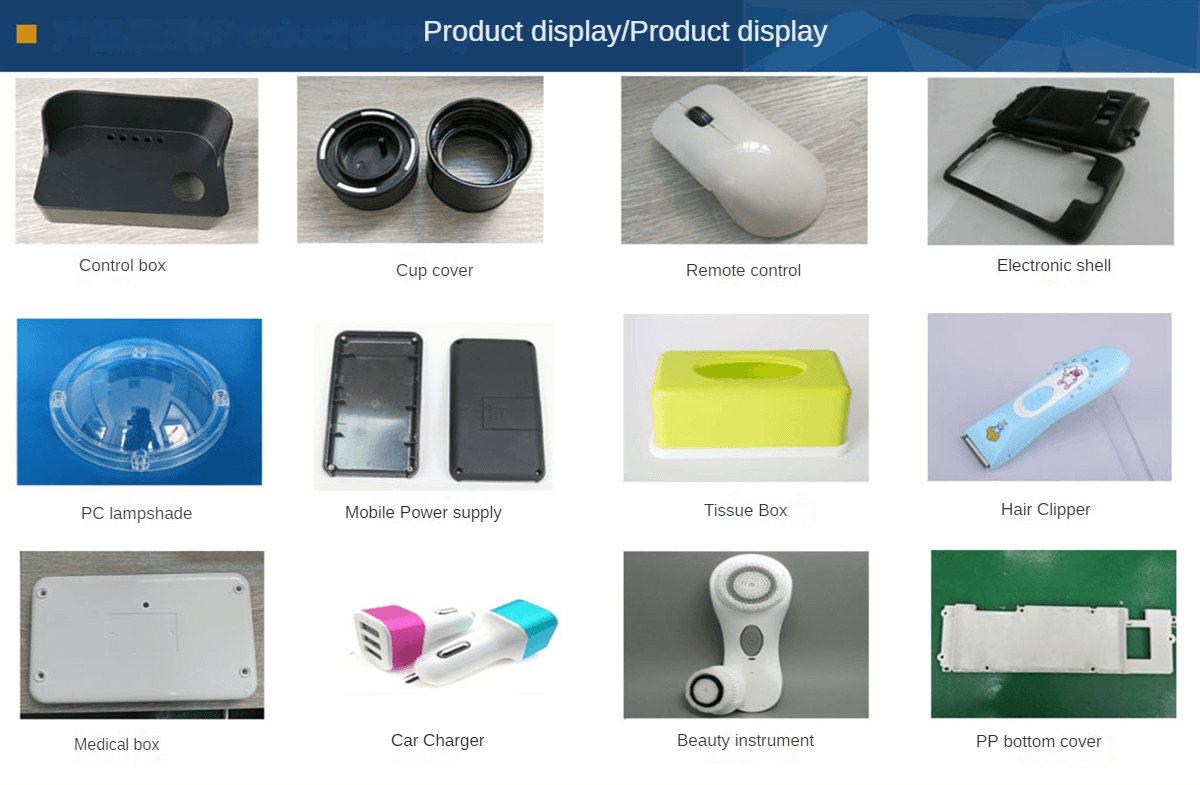

Moreover, hardware components manufacturers play a crucial role in the production process. They provide designers and engineers with the necessary tools and resources to create high-quality products that meet the demands of their target market. By working closely with manufacturers, designers can ensure that their products are not only functional but also aesthetically pleasing and user-friendly.

In conclusion, plastic and metal hardware components have their own unique set of advantages that make them suitable for different applications and product designs. By understanding these advantages and working closely with manufacturers, designers can create high-quality products that meet the needs of their target market.

Articles related to the knowledge points of this article:

Promising Prospects for the Development of Hardware Accessories Manufacturing in Suzhou

Home decoration hardware accessories

Title: Nantongs Premier Imported Hardware Components Processing Shop