Understanding the Standard Hardware Configuration for Customized Furniture

Customized furniture is becoming increasingly popular in the market. However, understanding the standard hardware configuration is crucial to ensure that your customized furniture meets your requirements. Standard hardware includes screws, bolts, brackets, and other components that are commonly used to assemble furniture. These components are designed to meet specific standards to ensure durability, safety, and ease of assembly. It's important to choose the right hardware for your customized furniture as different materials require different types of hardware. For example, wood requires screws with a longer thread length, while metal requires bolts with a larger diameter. In addition to choosing the right hardware, it's also important to follow proper installation procedures to ensure that your furniture is secure and stable. By understanding the standard hardware configuration for customized furniture, you can make informed decisions about the type of hardware you need and how to install it properly. This will help you achieve the desired look and functionality of your customized furniture while ensuring its longevity and safety.

As consumers increasingly turn to customized furniture, it is essential to understand the role of hardware in ensuring the durability and functionality of these products. The hardware, or fittings, used in custom-built furniture refer to the screws, brackets, knobs, and other components that hold the pieces together. While some furniture makers may use basic hardware as a cost-cutting measure, a higher quality standard hardware configuration can significantly improve the overall quality and longevity of your customized furniture. In this article, we will discuss the common hardware configurations found in customized furniture and their importance.

1、Screws

Screws are perhaps the most ubiquitous type of hardware used in furniture construction. They are responsible for holding pieces together at various points along the frame, such as the corners, sides, and back. The choice of screw depends on factors such as the wood species, the weight of the piece being built, and the intended use of the furniture. Common screw types include machine screws (also known as pan heads), countersink screws, and anchor screws. Machine screws are typically used for lighter wood species and provide a clean, flush appearance when driven into the wood. Countersink screws are designed to sink into the wood, providing a more secure hold than machine screws and allowing for a deeper insertion point for additional support. Anchor screws are used to attach heavy pieces, such as tables and cabinets, and are typically made of steel or high-strength brass.

2、Brackets

Brackets are used to connect pieces of furniture that run parallel to each other but do not share a joint. For example, a bookshelf with multiple shelves might have brackets attached to the back of each shelf to support the weight of the books and prevent them from tipping over. Brackets come in various shapes and sizes, depending on the specific requirements of the furniture design. Some common bracket types include dowel brackets, mortise and tenon brackets, and angle brackets. Dowel brackets are easy to install and require minimal hardware, making them a popular choice for DIY furniture projects. Mortise and tenon brackets provide a stronger connection between pieces and are commonly used in cabinetry and furniture with decorative features. Angle brackets are versatile and can be used to connect pieces of different lengths and heights.

3、Knobs and Pulls

Knobs and pulls are small fittings used to control movement within furniture, such as drawers or doors. They can be made of various materials, including metal, wood, plastic, and glass. The choice of material depends on the style of the furniture and the desired level of durability. Metal knobs and pulls are often used in modern or contemporary furniture designs due to their sleek appearance and durability. Wooden knobs and pulls add a warm, organic touch to traditional or rustic furniture styles. Plastic knobs and pulls are lightweight and easy to clean, making them suitable for kitchen and bathroom cabinetry. Glass knobs and pulls are highly decorative and can add a touch of elegance to any piece of furniture.

4、Bolts

Bolts are used to connect pieces of furniture at their joints or corners. They provide additional support and stability to the joint between two pieces of wood or other materials. Bolts can be made of various materials, including steel, aluminum, and stainless steel. The strength of the bolt depends on the thickness of the material being joined and the weight of the furniture being assembled. Steel bolts are strong and durable but can rust if not properly maintained. Aluminum bolts are lightweight and resistant to rust but may notprovide as much support as steel bolts. Stainless steel bolts offer the best balance between strength, durability, and resistance to rust but are also more expensive.

5、Hinges

Hinges are mechanical devices used to join two pieces of wood or other materials together at their corners or edges. They allow for easy opening and closing of doors, drawers, or cabinets while maintaining their structural integrity. Hinge types include soft-close hinges (also known as self-closing), which close gently without causing damage to the door or drawer; ball-bearing hinges, which provide smooth operation and reduce friction; and pocket hinges, which eliminate the need for a separate hinge plate by attaching them to a hole in the edge of the door or drawer. The selection of hinge type depends on factors such as the weight of the furniture being assembled, the intended use of the piece, and personal preference.

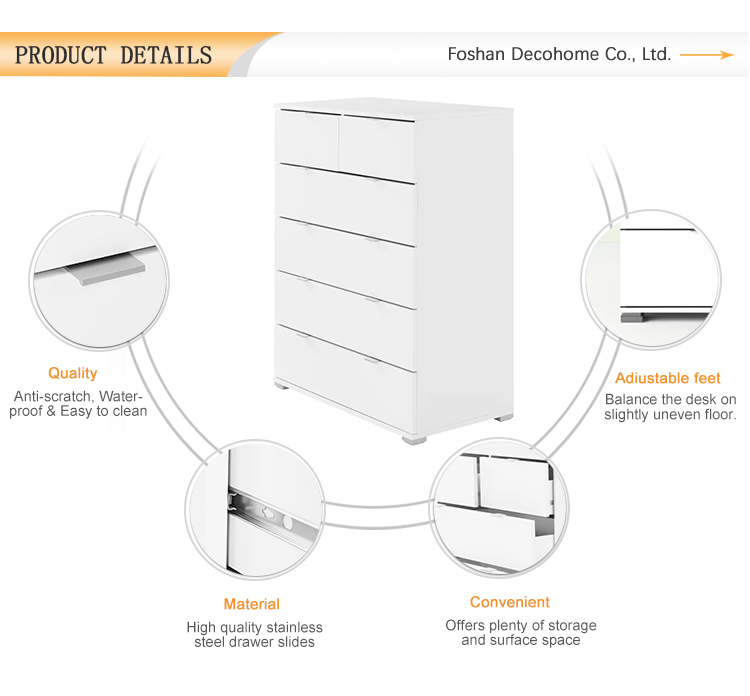

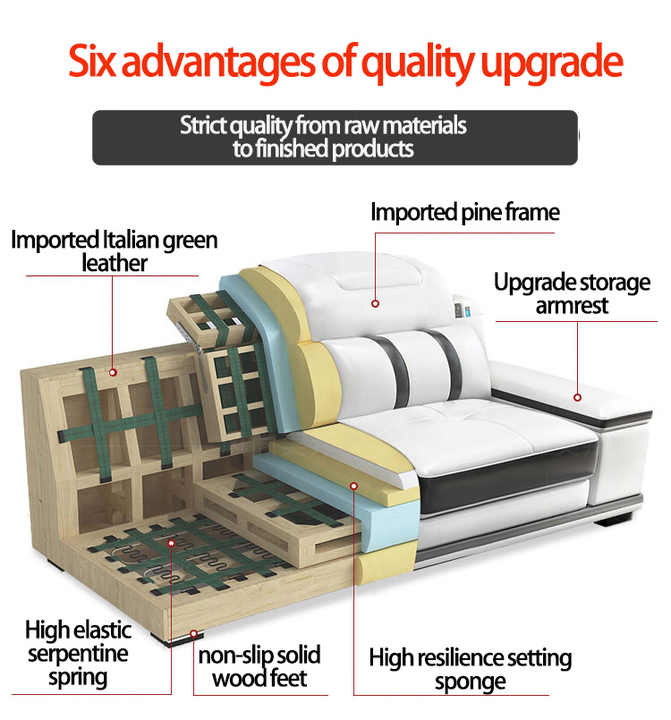

When choosing hardware for your customized furniture, it is essential to consider both its quality and quantity. A higher quality standard hardware configuration can provide better support, durability, and aesthetic appeal than cheaper alternatives. However, using too many or using low-quality components may actually weaken the joint between two pieces of wood or other materials, leading to instability or eventual failure. As such, it is crucial to strike a balance between cost-effectiveness and long-term reliability when selecting hardware for your custom-built furniture.

Articles related to the knowledge points of this article:

Title: The Promising Future of Xinjiang Metal Processing and Custom Manufacturing

Title: The Art of Customizing Metal模具货架 - A Comprehensive Guide

Title: Elevating Home Decor with Customized Bronze Furniture Hardware

Title: Hangzhou Customized Hardware Solutions