Hardware Components: The Pin and Screw

The hardware components of a device, particularly those found on the surface of the printed circuit board (PCB), are essential for its proper functioning. Two such critical components are the pin and screw. The pin, also known as a terminal, is a metal piece with an opening or through-hole that allows electrical signals to pass from the device's internal components to external devices. The screw, on the other hand, is a threaded fastener used to secure the PCB to other components or the machine frame. The screw head provides a surface area for soldering or attaching other components, while the threads allow for easy tightening and loosening of the screw. Both the pin and screw play a crucial role in ensuring the proper connection between various parts of the PCB and maintaining its stability during use. Without these hardware components, the device would not function correctly, leading to potential malfunctions and damage to its internal components. Therefore, it is essential to ensure the correct selection, placement, and securing of these components during PCB assembly to achieve efficient and reliable device performance.

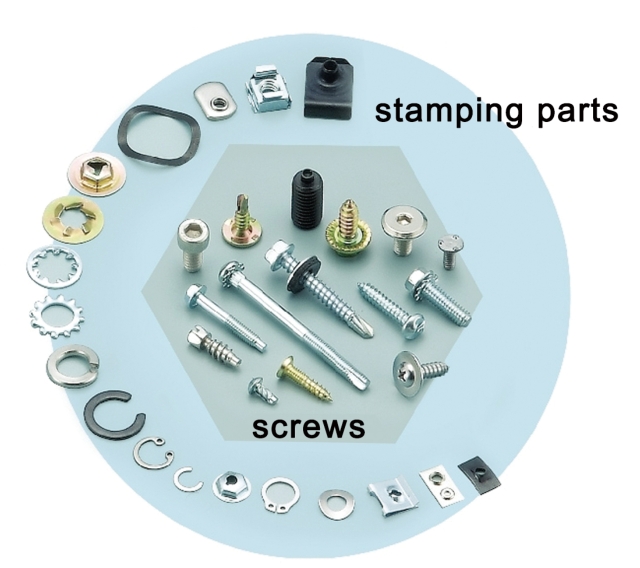

In the realm of industrial design and manufacturing, hardware components play a crucial role in the functionality and aesthetics of various products. Among these components, the pin and screw stand out as versatile and essential elements that connect, secure, and reinforce structures. This article delves into the significance of pin and screw hardware, its evolution over time, and its application in diverse fields.

The Evolution and Significance of Pin and Screw Hardware

Pins and screws have been in existence for thousands of years, with evidence of their use dating back to ancient civilizations such as Egypt, Greece, and Rome. However, it was not until the Industrial Revolution that these basic fasteners gained widespread popularity and became an integral part of modern manufacturing processes. The development of metallurgical techniques allowed for the creation of high-quality pins and screws made from various metals such as iron, steel, aluminum, and titanium. Today, pins and screws come in a wide range of shapes, sizes, materials, and heads designed to cater to specific applications.

One of the primary advantages of using pins and screws is their simplicity and ease of use. They require minimal tools to install or repair, making them suitable for various DIY projects and professional maintenance tasks. Additionally, pins and screws are highly versatile; they can be used to join different materials such as wood, plastic, rubber, and even metal itself. This adaptability makes them ideal for a variety of applications, including construction, automotive assembly, aerospace engineering, consumer electronics, and medical devices.

Furthermore, pins and screws contribute significantly to the sustainability of products by reducing waste during disposal. Unlike other fasteners such as nails or bolts, which can be difficult to remove without causing damage to the surrounding material, pins and screws leave minimal residue once installed. This feature makes them ideal for applications where environmental impact is a concern, such as renewable energy projects or waste management initiatives.

Applications of Pin and Screw Hardware

The versatility and practicality of pins and screws make them indispensable in various industries. In the construction sector, they are commonly used for joining wooden frames, metal studs, and other building components. Pins and screws also play a vital role in automotive assembly, where they secure engine parts, transmission lines, and other vehicle systems. In the aerospace industry, pins and screws are employed in aircraft manufacturing to assemble fuselages, wings, and other critical components.

Consumer electronics are another field where pins and screws have found extensive usage. From mobile phones to computers and appliances, electronic devices rely on pins and screws to hold together various components such as circuit boards, speakers, and power buttons. In addition, healthcare professionals use specialized screws made from stainless steel or titanium to secure surgical instruments during procedures. These screws offer superior resistance to corrosion, making them ideal for applications involving blood or body fluids.

Moreover, the use of pins and screws extends beyond traditional industrial settings. The DIY market has embraced these fasteners as an easy way to create customized furniture pieces, jewelry designs, and other household decorations. The ability to attach ordetach items with relative ease has made pins and screws an essential tool for creative individuals who enjoy working with their hands.

Conclusion

Pins and screws may appear mundane at first glance; however, their impact on society cannot be underestimated. Their simplicity, adaptability, and sustainability have made them invaluable components in various industrial settings. As technology continues to advance, so will our reliance on pins and screws for connecting, securing, and reinforcing structures. Whether in the boardroom or the workshop floor, these basic fasteners remain a cornerstone of modern manufacturing and innovation.

Articles related to the knowledge points of this article:

Lanzhou Hardware Accessories: Quality and Reliability for Your Projects

Title: Quotation for New Energy Hardware Parts in Shangyuan District

Shoe Buckle Hardware Accessories: Key Components for Shoe Production

A Comprehensive Comparison of Hardware Prices in Jiangxi: An Insight into the Local Market

Title: Exploring the World of Wholesale Cabinet Hardware Suppliers: A Comprehensive Guide