The Comprehensive Design of Metal Parts and Components

In the field of metal manufacturing, the design and production of metal parts and components is a crucial process that requires careful consideration of various factors such as material selection, shape, size, and function. To address these challenges, the Comprehensive Design of Metal Parts and Components (CDPMCP) has emerged as a comprehensive approach that incorporates advanced technologies, engineering principles, and design methodologies to optimize the performance and functionality of metal components. The CDPMCP involves a multidisciplinary approach that involves collaboration between engineers, designers, and scientists to develop innovative solutions that meet the unique needs of each project. This approach emphasizes the use of computer-aided design (CAD) software and other simulation tools to model and test different designs before committing to physical production. Moreover, the CDPMCP places great emphasis on sustainability and environmental responsibility, with a focus on reducing waste and minimizing the impact of metal production on the environment. This includes the use of recycled materials, energy-efficient production processes, and eco-friendly design concepts. Overall, the CDPMCP represents a significant step forward in the field of metal manufacturing by providing a holistic and collaborative approach to designing and producing metal components that are efficient, durable, and sustainable. By embracing this approach, manufacturers can stay ahead of the competition while also meeting the growing demand for high-quality metal products in various industries.

Introduction

The design of metal parts and components plays a crucial role in the functionality, durability, and overall performance of any product. It involves various aspects such as material selection, shape and form optimization, assembly, and mechanical properties evaluation. This article aims to provide an in-depth overview of the design process for metal parts and components, covering key topics such as material properties, design techniques, and industry standards.

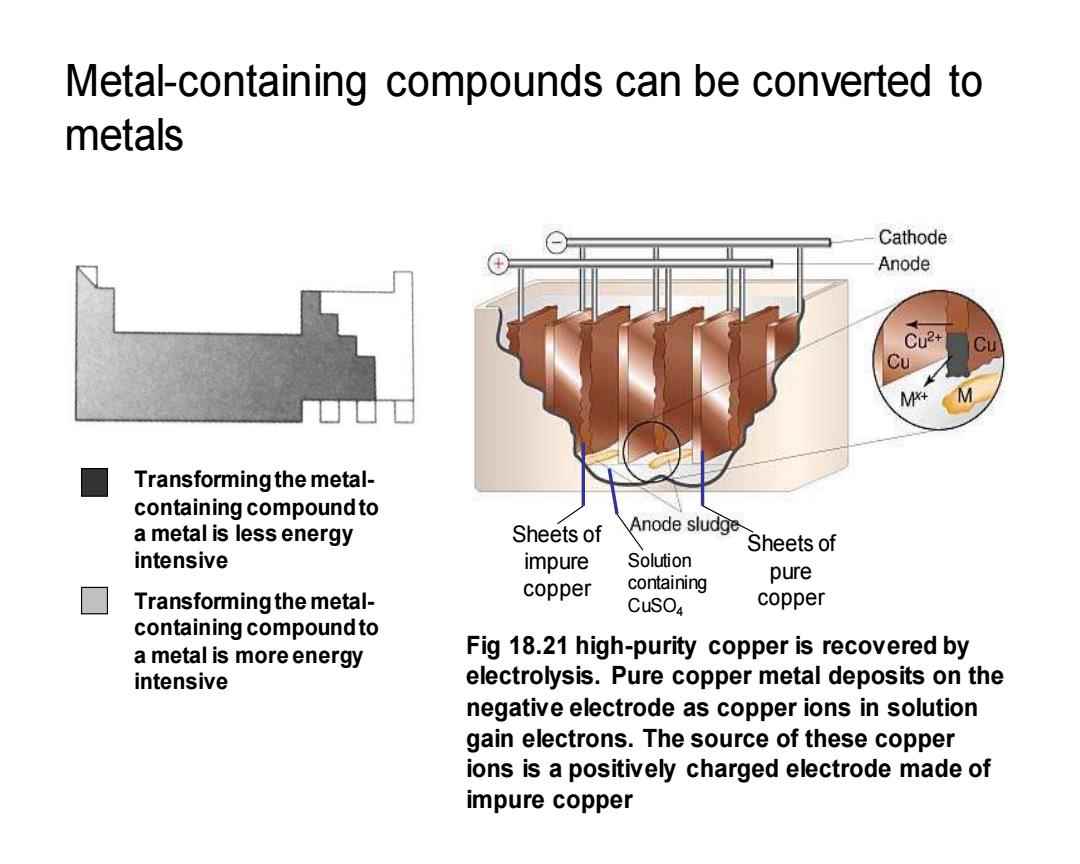

Material Selection

The first step in designing metal parts and components is to choose the appropriate material based on its physical and chemical properties. Metals can be classified into several categories, including metals with high tensile strength, metals that are resistant to corrosion, and metals that have excellent thermal conductivity. Each metal has unique characteristics that affect its application in different engineering fields. Some of the commonly used metals for metal part design include aluminum, steel, titanium, and magnesium.

Shape and Form Optimization

Once the material has been selected, the next step is to optimize the shape and form of the part. This involves determining the most efficient way to use the available material volume while meeting the required functional requirements. There are several design techniques that can be employed to optimize shape and form, including 3D printing, computer-aided design (CAD), and computational fluid dynamics (CFD). These techniques allow designers to create complex shapes and geometries that were previously impossible or impractical to produce using traditional manufacturing methods.

Assembly and Manufacturing Processes

After the shape and form of the part have been optimized, it is necessary to consider how it will be assembled and manufactured. Different assembly techniques can be used depending on the complexity of the part and the materials used. For example, simple assemblies may require manual labor, while more complex assemblies may require specialized equipment such as robots or automated assembly lines. Manufacturing processes can also vary greatly depending on the material and part size. Common manufacturing processes include stamping, welding, drilling, milling, and grinding.

Mechanical Properties Evaluation

The final step in designing metal parts and components is to evaluate their mechanical properties. This involves assessing factors such as strength, stiffness, fatigue life, ductility, and vibration resistance. Mechanical properties are critical because they determine how well the part will perform in its intended application. To evaluate these properties, engineers use a variety of tools and techniques such as stress analysis, load testing, and fracture mechanics. In some cases, additional testing may be required to verify the results obtained from these analyses.

Industry Standards and Guidelines

In addition to following best practices in metal part design, engineers must also adhere to industry standards and guidelines. These standards provide guidance on factors such as safety regulations, environmental impact assessments, and quality control procedures. Industry standards for metal parts and components vary depending on the country and region in which they will be used. For example, the International Organization for Standardization (ISO) provides international standards for many industrial sectors, including metal parts design.

Conclusion

Designing metal parts and components requires careful consideration of multiple factors, including material selection, shape and form optimization, assembly, mechanical properties evaluation, and adherence to industry standards and guidelines. By following best practices and utilizing advanced design techniques, engineers can create parts that meet the highest standards of performance and functionality. As technology continues to advance, we can expect new innovations in metal part design that will further enhance the efficiency and effectiveness of various industries worldwide.

Articles related to the knowledge points of this article:

Title: Quality Inspection of Window Wall Hardware Accessories in Hangzhou

Title: Customizing Metal Hardware Solutions in Qingdao: A Comprehensive Guide

Title: Exploring the World of Foshan Quality Hardware Accessories Retail: An In-Depth Analysis

Title: Understanding the Cost of Electronic Hardware Assembly in Guangzhou

Title: Comprehensive JIAZHANG NUCLEOGENIC POWER PLANT HARDWARE ACCESSORIES PRICE LIST

Fan Hardware Accessories: An Integral Part of the Fan Industry