Shenzhen Hardware Processing Customization: The Ultimate Guide

Shenzhen Hardware Processing Customization: The Ultimate Guide provides a comprehensive overview of hardware processing customization in Shenzhen, China. This guide covers the entire process, from understanding customer needs to finalizing the product. It highlights the various stages of hardware processing, including material selection, design, machining, assembly, and testing. Additionally, it discusses the benefits of hardware processing customization and how it can help businesses achieve their goals. Finally, this guide provides contact information for reliable hardware processing providers in Shenzhen.

Shenzhen, a city in southern China, has become a major hub for hardware processing and customization due to its advanced manufacturing capabilities and proximity to Hong Kong and other international markets. This guide will explore the intricacies of hardware processing customization in Shenzhen, including the various types of services available, the materials commonly used, and the production process from start to finish.

Types of Hardware Processing Customization in Shenzhen

Shenzhen's hardware processing industry offers a wide range of customization services to meet the diverse needs of its clients. Some of the most common types of customization include:

1、Metal Cutting: This service involves using cutting tools to remove material from a metal workpiece to create a desired shape or feature. Metal cutting can be done using CNC machines, which are capable of handling complex shapes and precision cuts.

2、Milling: Milling is a subtractive manufacturing process that involves removing material from a workpiece using a rotating milling cutter. This process can be used to create intricate shapes and features on both hard and soft materials.

3、Turning: Turning is a machining process that involves using a lathe to remove material from a workpiece while it is rotating. This process is commonly used to create cylindrical shapes, such as shafts, gears, and bearings.

4、Drilling: Drilling is a process that involves using a drill bit to create holes in a workpiece. This process can be done using CNC drilling machines, which can handle multiple drill operations simultaneously.

5、Tapping: Tapping is a threading process that involves using a tap bit to create internal threads in a drilled hole. This process is commonly used to create threaded holes for fasteners or to create a keyed connection between two parts.

Materials Used in Hardware Processing Customization

Shenzhen's hardware processing industry uses a wide range of materials to meet the diverse needs of its clients. Some of the most common materials include:

1、Metals: Metals are commonly used in hardware processing due to their strength, durability, and ability to withstand high temperatures and harsh environments. Common metals used include steel, aluminum, copper, brass, and stainless steel.

2、Plastics: Plastics are lightweight and easy to machine materials that are commonly used in hardware processing applications. They are often used to create components that require high precision but low strength, such as gears, bearings, and seals.

3、Composites: Composites are materials made up of two or more different materials that are combined together to create a new material with unique properties. Common composites used in hardware processing include carbon fiber reinforced plastic (CFRP), glass fiber reinforced plastic (GFRP), and nylon-based composites.

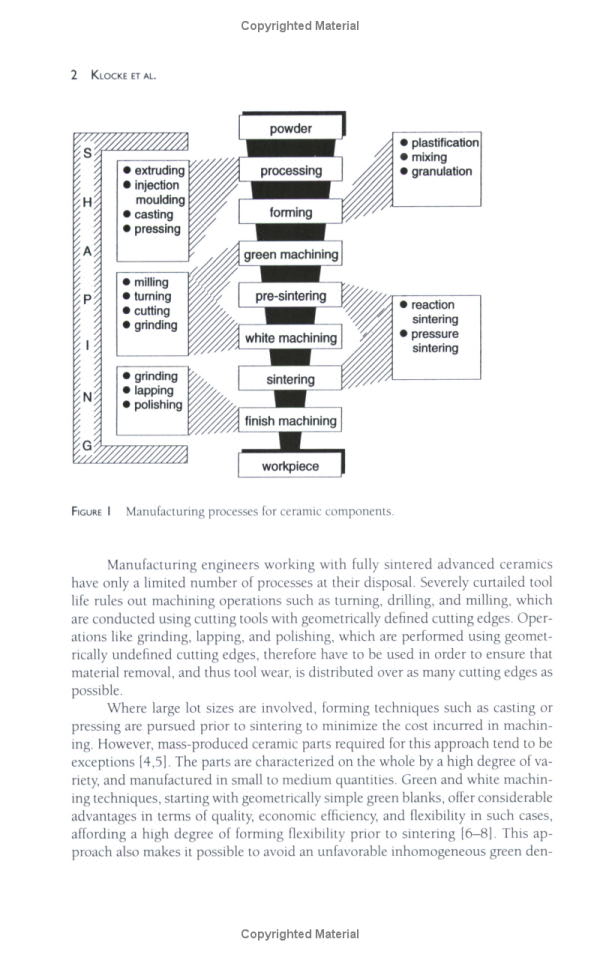

4、Ceramics: Ceramics are inorganic, non-metallic materials that are commonly used in hardware processing applications due to their high hardness, low thermal conductivity, and excellent chemical resistance. Common ceramics used include alumina, zirconia, and silica.

Production Process of Hardware Processing Customization

The production process of hardware processing customization in Shenzhen typically follows these steps:

1、Design: The first step is to create a design for the desired hardware component using CAD (computer-aided design) software. The design will specify the shape, size, material, and other important details of the component.

2、Material Selection: Next, the appropriate material for the component is selected based on the requirements of the application and the availability of the material in Shenzhen's market.

3、Cutting & Milling: Once the material is selected, it is cut and milled into the desired shape using CNC machines or other cutting tools. This step requires precision cutting to ensure accurate dimensions and smooth surfaces.

4、Turning & Drilling: Next, any necessary turning or drilling operations are performed on the workpiece to create the desired features or holes. These operations can be done using CNC turning machines or drilling machines equipped with precision tools.

5、Tapping & Other Operations: Finally, any tapping or other secondary operations are performed to complete the component's manufacture. These operations may include adding threads or other features to enhance the component's functionality or appearance.

6、Quality Inspection: After all manufacturing operations are completed, each component undergoes a quality inspection process to ensure it meets the specified standards for dimension, shape, and surface finish. Components that do not meet these standards are rejected and either repaired or reprocessed as necessary.

7、Packaging & Shipping: Once all components have passed quality inspection, they are packaged for shipping either directly to the customer or through intermediaries based on the customer's requirements for packaging and shipping arrangements.

Conclusion

Shenzhen's hardware processing industry has become one of the most important hubs for hardware processing customization due to its advanced manufacturing capabilities and proximity to international markets like Hong Kong. By understanding the types of services available in Shenzhen's hardware processing industry as well as the materials commonly used and production process followed by manufacturers like those at Pacific Precision Engineering Ltd., it becomes easier for businesses seeking hardware

Articles related to the knowledge points of this article:

Whole-House Custom Functional Hardware

Customizing Jiangsu Hardware Oven for Baking

Custom Door Hinge Manufacturing Factory: The Art of Crafting Perfect Hardware

Anhui Customized Hardware Brands

Title: Customizing Window Hardware for Qinghai: A Comprehensive Guide

Metal Processing and Custom Manufacturing Services in Guangdong, China: An Overview