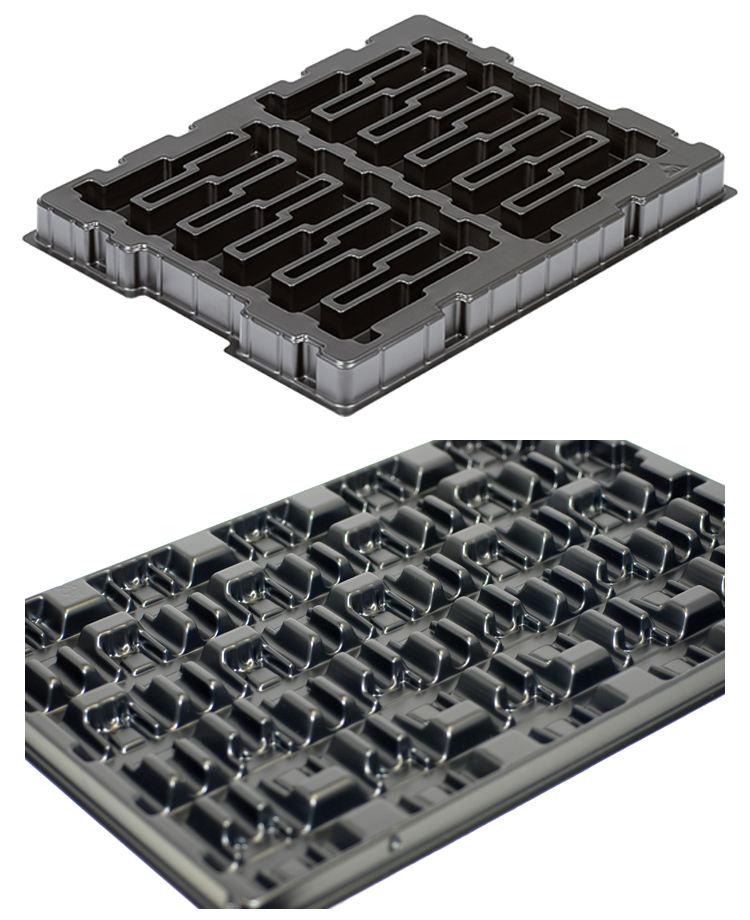

Title: The Art of Manufacturing Metal Components Reprocessing Trays

The art of manufacturing metal components reprocessing trays involves a meticulous process that requires skill and precision. Firstly, the raw materials are carefully selected based on their strength, durability, and corrosion resistance. Then, the metal is heated to a specific temperature and shaped into the desired shape using specialized machinery. Once the trays are formed, they are cleaned thoroughly to remove any impurities or marks. The surface is then treated with a coating material to enhance its resistance to wear and tear. Finally, the trays are tested for quality and compliance with industry standards before being packaged and shipped out for use. The manufacturing process of metal component reprocessing trays is not only important for ensuring product quality but also plays a crucial role in reducing waste and environmental impact. By adopting advanced technology and sustainable practices, manufacturers can create cost-effective and eco-friendly solutions for reprocessing metal components.

Introduction:

The manufacturing industry has been evolving over the years, and one area that has seen significant growth is the metal component reprocessing trays. These trays are used to manage and store various metal parts during the recycling process. They come in handy for industries such as automotive, electronics, and construction, which rely heavily on metal components. This article explores the art of manufacturing metal component reprocessing trays, focusing on the key players in this industry – the五金配件周转盘制造商.

Understanding the Importance of Metal Component Reprocessing Trays:

Metal component reprocessing trays play a vital role in maintaining the efficiency and safety of the recycling process. They help to organize and protect metal parts during transportation, storage, and processing. Without these trays, metal recycling would be challenging and potentially dangerous.

Key Players in the Metal Component Reprocessing Tray Manufacturing Industry:

The manufacturing of metal component reprocessing trays involves several steps, including design, production, and quality control. Several companies specialize in this industry, each with its unique approach and expertise. In this article, we will explore the key players in the metal component reprocessing tray manufacturing industry – the五金配件周转盘制造商.

1. A-One Industries:

A-One Industries is a leading manufacturer of metal component reprocessing trays. With over two decades of experience in the industry, the company offers a comprehensive range of custom-designed trays tailored to meet specific customer needs. Their product portfolio includes standard and bespoke trays, as well as containers for hazardous materials. A-One Industries prides itself on using high-quality materials and state-of-the-art equipment to ensure consistent product quality and durability.

2. B-Built Manufacturing:

B-Built Manufacturing is a family-owned business that specializes in manufacturing metal component reprocessing trays. The company has built a reputation for producing high-quality trays at competitive prices. They offer both standard and customized designs, with the ability to accommodate different shapes and sizes of metal parts. B-Built Manufacturing uses only premium-grade materials to ensure longevity and resistance to wear and tear.

3. C-Creative Metal Products:

C-Creative Metal Products is a dynamic manufacturer of metal component reprocessing trays. The company focuses on providing innovative solutions to meet customer needs while minimizing environmental impact. They offer a range of eco-friendly options, including recycled materials and biodegradable products. C-Creative Metal Products also collaborates with customers to develop custom-designed trays that suit their specific requirements.

4. D-Direct Metal Solutions:

D-Direct Metal Solutions is a mid-sized manufacturer that specializes in metal component reprocessing trays for various industries. The company has a team of experienced engineers who work closely with customers to design custom-made trays that cater to their unique needs. D-Direct Metal Solutions uses advanced production techniques and cutting-edge equipment to ensure consistent quality and efficiency throughout the manufacturing process. They also prioritize environmental sustainability by using eco-friendly materials whenever possible.

Advantages of Working with Metal Component Reprocessing Tray Manufacturers:

Working with a reputable metal component reprocessing tray manufacturer can bring numerous benefits to your business, including:

* Access to high-quality products: Manufacturer partners typically have a proven track record of producing durable and reliable trays that meet industry standards.

* Timely deliveries: Manufacturing partners can guarantee timely delivery of orders, helping you maintain operational efficiency and minimize downtime.

* Customizable solutions: Experienced manufacturers can provide tailor-made trays that meet your specific needs, ensuring maximum productivity and efficiency.

* Cost savings: By partnering with a manufacturer, you may be able to negotiate better pricing terms or enjoy bulk discounts on your orders.

* Environmental responsibility: Choosing a manufacturer with a focus on sustainability can help reduce your carbon footprint and contribute to a greener future for the planet.

Articles related to the knowledge points of this article:

Handrail Hardware Fittings: A Comprehensive Guide

Tent Hardware Accessories: An Essential Guide

Title: Shanghais Nuclear Power Hardware Accessory Quotation Network: A Comprehensive Guide