Stamping Hardware Manufacturers: A Closer Look

Stamping hardware manufacturers have long played a crucial role in various industries, providing essential components and parts for a wide range of applications. These manufacturers have specialized in creating precision-stamped hardware using high-quality materials and advanced manufacturing techniques. By closely examining the stamping hardware manufacturing process, it becomes apparent that these manufacturers play a significant role in terms of quality control, material selection, and process efficiency.Quality control is essential in stamping hardware manufacturing, as even minor defects can result in significant performance issues or even product failure. Manufacturers typically employ a series of quality checks at each stage of the manufacturing process to ensure that each part meets the specified standards. This attention to detail ensures that the end product is reliable and durable.Material selection is another crucial aspect of stamping hardware manufacturing. Manufacturers must carefully choose the right materials to ensure that the stamped hardware will have the desired mechanical properties, such as strength, hardness, and wear resistance. By understanding the unique characteristics of each material, manufacturers can tailor their selection to meet the specific requirements of each application.Process efficiency is also essential in stamping hardware manufacturing. Manufacturers strive to optimize their manufacturing processes to reduce costs and improve productivity. This often involves automating tasks, implementing lean manufacturing techniques, and using advanced production equipment. By focusing on process efficiency, manufacturers can offer competitive pricing while maintaining high quality standards.In conclusion, stamping hardware manufacturers play a vital role in supplying precision-stamped hardware to various industries. Their commitment to quality control, material selection, and process efficiency ensures that the end products are reliable, durable, and cost-effective.

Stamping hardware manufacturers are a crucial part of the manufacturing industry, providing a range of products from simple metal stampings to complex machinery components. These manufacturers use specialized equipment and processes to create high-quality, precision-crafted products that are used in various industries such as automotive, aerospace, electronics, and more.

In this article, we will explore the world of stamping hardware manufacturers, looking at their role in the manufacturing process, the types of products they produce, and the essential qualities that make them successful in their field.

Role in the Manufacturing Process

Stamping hardware manufacturers play a crucial role in the manufacturing process by providing the necessary components and parts that are used to assemble finished products. These manufacturers work closely with designers and engineers to create products that meet the specific needs of each industry. By using precision stamping techniques, they are able to produce high-quality, accurate parts that are essential for the smooth operation of machines and equipment.

Types of Products Produced

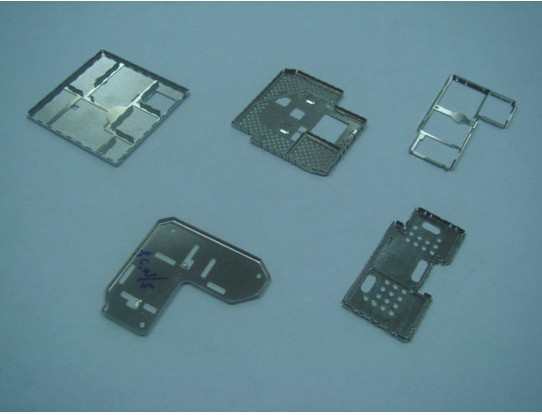

Stamping hardware manufacturers produce a wide range of products, including but not limited to:

1、Metal stampings: These are thin metal pieces that are stamped out using specialized presses. They are often used in the automotive industry for creating body panels, interior components, and more.

2、Machinery components: These are larger, more complex parts that are used in machines and equipment. They may include gears, shafts, and other mechanical components.

3、Electronics hardware: Stamping hardware manufacturers also produce electronic components such as circuit boards, connectors, and other parts that are essential for the functioning of electronic devices.

Essential Qualities of Successful Stamping Hardware Manufacturers

In order to succeed in the stamping hardware manufacturing industry, manufacturers must possess certain essential qualities. These qualities include:

1、Precision: Stamping hardware manufacturers must have a high level of precision in their work. This precision ensures that each part produced meets the exact specifications required for its intended use. By using precision stamping techniques, manufacturers can ensure that each part is accurately shaped and sized, reducing the risk of errors or defects in the final product.

2、Quality Control: Quality control is essential for any manufacturing industry, but it is particularly important for stamping hardware manufacturers. By implementing strict quality control measures, manufacturers can ensure that each part produced is inspected and tested for defects before being shipped to customers. This approach not only ensures high-quality products but also builds trust with customers who can rely on consistent, reliable performance from their hardware components.

3、Innovation: Innovation is key to success in any industry, and stamping hardware manufacturing is no exception. Manufacturers must constantly seek new ways to improve their processes and products to stay competitive in an ever-evolving market. By investing in research and development, manufacturers can explore new materials, techniques, and designs that will help them create better products for their customers.

4、Collaboration: Collaboration is essential for stamping hardware manufacturers to succeed in their field. By working closely with designers and engineers, manufacturers can ensure that their products meet the specific needs of each industry. Additionally, collaborating with other manufacturers can help them source high-quality raw materials or subcontract services that are necessary for their production process.

In conclusion, stamping hardware manufacturers play a crucial role in the manufacturing process by providing high-quality, precision-crafted products that are essential for various industries. By possessing essential qualities such as precision, quality control, innovation, and collaboration, these manufacturers can succeed in their field and build trust with customers who rely on their products for smooth operation and performance.

Articles related to the knowledge points of this article:

Triple Combination Hardware Manufacturers: The Ultimate Guide

Changzhou Hardware Manufacturers